All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(20884 products available)

electronic part mold are essential parts of the manufacturing sector that help to shape raw materials into desired forms. From household goods to automobile parts, these instruments are made from plastic, metal, or other materials into precise forms to produce a range of products. Applications for electronic part mold abound and include blow moulding, injection moulding, and compression moulding. Their dependability and accuracy are essential for guaranteeing the consistency and quality of the end goods. The design and utility of electronic part mold change with technology, providing more production process adaptability and efficiency as well as more evolution.

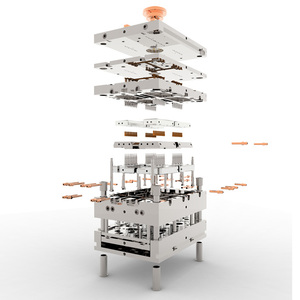

The market features various varieties of electronic part mold, each intended for certain uses. Injection moulds are among the most often utilized. They are used mostly in the mass manufacture of plastic components. Two sections of these moulds create a cavity into which molten plastic is pumped. By inflating hot plastic inside a mould chamber, hollow objects, such as bottles and containers are made using blow moulds. Conversely, heat and pressure applied in compression moulds help shape thermosetting plastics. Depending on the needs of the manufacturing process, every type of electronic part mold presents special benefits including speed, precision, and economy.

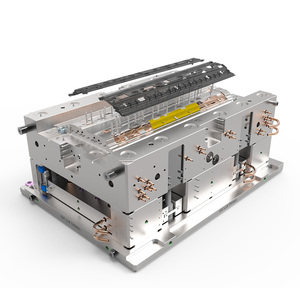

electronic part mold have several purposes that are vital for the manufacturing process. They offer the framework and shape required to create consistently excellent goods. Precision engineering, durability, and material as well as production method adaptation are among electronic part mold main features. Essential for preserving quality standards, the accuracy of these moulds guarantees less material waste and uniform product dimensions. Modern electronic part mold also are made to be robust and able to tolerate the high heat and pressures of moulding operations. This durability guarantees a long lifespan and lowers the demand for regular replacements, therefore maximizing manufacturing efficiency.

Building electronic part mold calls for several materials selected depending on the intended use and the type of product being produced. Common materials have different qualities and include steel, aluminum, and other alloys. Because of its strength and wear resistance, steel is sometimes chosen for big-volume manufacture. For lower-volume applications and prototyping, aluminum is appropriate since it is lightweight and easier to process. The material choice affects the performance, longevity, and cost-effectiveness of the mould, so producers can customize electronic part mold to fit their particular requirements. Composite materials are progressively employed to improve moulding capabilities and lower environmental impact as technology develops.

Using electronic part mold successfully calls for a complete awareness of their capabilities and constraints. Extending the life of the mould and guaranteeing the best performance depends on proper maintenance and handling. Frequent cleaning and inspection help to guarantee moulding process precision and prevent damage. The product's material and design will help in choosing the suitable type of mould. Furthermore, cutting-edge technology such as computer-aided design (CAD) and computer-aided manufacturing (CAM) can be used to improve electronic part mold accuracy and efficiency. Higher quality goods and lower manufacturing costs are outcomes producers can get by streamlining these operations.

Choosing the suitable electronic part mold for any production line requires careful evaluation of numerous elements. Among the most crucial factors is the material intended to be handled. Different materials are needed for particular electronic part mold designs to guarantee the best durability and shape. For thermoplastics, injection moulds are the best; for thermosetting plastics, compression moulds are more appropriate. Achieving the intended product quality and efficiency depends on matching the electronic part mold type with the content.

Another important consideration in selecting electronic part mold design, is complexity. Complex forms and detailed elements could call for sophisticated moulding methods and precision engineering. Think about the electronic part mold capabilities in terms of tolerances and feature production capacity. Furthermore, the planned production volume can affect the decision since high-volume manufacturing might need sturdy materials like steel for the electronic part mold construction to resist frequent use.

Injection electronic part mold and compression moulds have diverse uses and functions. Injection moulds are appropriate for producing intricate forms and large-volume manufacturing because they allow molten material to be injected into a cavity. Conversely, typically utilized in thermosetting polymers, compression electronic part mold forms materials use heat and pressure. The material, degree of design complexity, and manufacturing requirements will determine which of these two to use.

Optimizing the usage of electronic part mold in production depends on technology. Perfect and quick mould fabrication is made possible by tools including computer-aided design (CAD) and computer-aided manufacturing (CAM). These systems can guarantee the electronic part mold satisfies the required criteria, replicate the moulding process, and forecast possible problems. Using these developments might help lower production costs and improve the quality of products.

Maintaining electronic part mold lifespan and performance depends on proper maintenance. Consistent cleaning helps to eliminate residue and stop damage. Examining the electronic part mold for wear and tear will assist in spotting problems early on, enabling quick repairs. Maintaining the mould's accuracy and usefulness depends partly on lubrication and calibration. Following these guidelines will help electronic part mold have a much longer lifetime.

Indeed, electronic part mold can be tailored to particular manufacturing techniques and product designs. Customizing the mould could mean changing its dimensions, form, or material to fit certain needs. This flexibility enables producers to customize electronic part mold to get the exact features and dimensions of products. Modern design tools help to create bespoke moulds that satisfy specified criteria.

Selecting the appropriate electronic part mold might be difficult given the several elements that have to be taken into account. Critical components are material compatibility, design complexity, manufacturing volume, and cost. Furthermore, future scalability and technical requirements should be considered. These difficulties call for careful investigation to make sure the chosen electronic part mold fits the manufacturing objectives and capabilities.