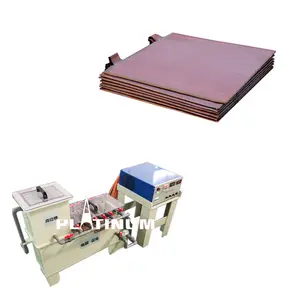

Electrolytic Etching Machine: An Introduction

An electrolytic etching machine is a powerful tool designed for precision metal marking and engraving. Utilizing electrochemical processes, these machines effectively etch intricate designs onto various metallic surfaces. They are popular in industries such as manufacturing, jewelry, and art, providing a versatile solution for customizing products and components. With the ability to create sharp, clear designs, electrolytic etching machines enhance branding, identification, and decorative applications.

Types of Electrolytic Etching Machines

Electrolytic etching machines come in several types, each catering to different operational needs and user preferences. Understanding these types can help you select the right machine for your specific requirements.

- Portable Electrolytic Etching Machines: Ideal for on-site marking, these compact devices are easy to transport and operate.

- Desktop Models: Designed for stability and precision, these machines are perfect for workshop environments.

- Automated Electrolytic Etchers: These high-tech machines integrate computer control for mass production and repetitive tasks, ensuring consistency in output.

- Handheld Etchers: Great for small tasks, these devices offer flexibility and ease of use for personal projects.

Applications of Electrolytic Etching Machines

The versatility of electrolytic etching machines allows them to be employed across various sectors. Here are some of the common applications:

- Metal Identification: Used to engrave serial numbers, barcodes, and logos on metals for easy traceability.

- Jewelry Making: Perfect for intricate designs on pieces, adding unique touches to custom jewelry items.

- Industrial Parts Marking: Ideal for creating marks on machinery and components that withstand harsh environments.

- Artistic Projects: Enabled artists and crafters to explore metalworking with detailed designs and personalization.

Features and Advantages of Electrolytic Etching Machines

Electrolytic etching machines come packed with features that make them a preferred choice for professionals and hobbyists alike. Here are some standout features and the key advantages they provide:

- Precision Marking: They offer high levels of accuracy, resulting in clean and detailed engravings.

- Speed and Efficiency: These machines operate rapidly, significantly reducing production times while maintaining quality.

- Eco-Friendly Operation: Electrolytic etching utilizes minimal chemicals, making it an environmentally friendly option.

- Low Maintenance: With fewer mechanical parts exposed to wear, these machines typically require minimal upkeep.

- Versatility: Capable of working on various metals, including stainless steel, aluminum, and copper, broadening their usability