All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1032 products available)

Edon pumps cover a wide range of industrial and consumer applications. Here are some key types of pumps from Edon:

Edon Centrifugal Pumps:

Centrifugal pumps convert rotational energy into fluid flow. They feature an impeller that rotates within the casing. The rotating impeller applies centrifugal force to the fluid, pushing it outwards from the center, thereby generating flow. Fire fighting centrifugal pumps are specially designed to fight fire. They are made to transfer high volumes of water in a short space of time. Clean water centrifugal pumps are used to transfer non-viscous liquids such as water, light oil, liquid food, etc. They work by converting the electro-motive force into fluid energy. Solar water centrifugal pumps use solar energy to convert it into electric energy through the solar panel, and then it drives the motor of the pump to move water. Sewage centrifugal pumps are designed to transport wastewater containing solids and debris. They typically have durable materials and clog-resistant impellers to handle the harsh conditions of sewage systems.

Edon Submersible Pumps:

Submersible pumps are sealed to make them suitable for underwater use. They have a sealed motor that drives the pump, which is also submerged in the fluid being pumped. A typical application of submersible pumps is to drain water from an underground mine or well.Or they are used in agricultural fields for irrigation systems. The deep well submersible pump is made to work in water wells. It is designed for continuous submerged operation. The pump draws water from an underground aquifer through a vertical well casing. The vertical configuration and sealed design of deep well submersible pumps allows them to reach great depths and supply clean drinking water from wells.

Edon Screw Pumps:

Edon screw pumps use screw rotors to transfer fluids. The screws rotate in a fixed cavity, generating a pressure differential that pushes the fluid forward. They work fine with high-viscosity fluids such as oil, asphalt, etc. Double screw pumps have a driving screw and a driven screw. The work of pumping the fluid is shared. The efficiency is high. Meanwhile, the liquid has little interruption and remains uninterrupted transfer. Power screw pumps have an exterior helical gear that provides the power to move the screw. This helps the pump to be used in numerous areas, such as the marine industry for oil transfer, lubrication systems, and chemical processing equipment.

Edon Diaphragm Pumps:

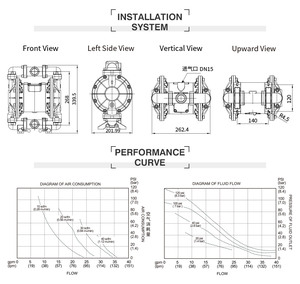

Diaphragm pumps consist of a diaphragm that moves back and forth to change the volume of the pump chamber. This movement creates a pressure difference that sucks up the liquid and ejects it, making the flow possible. Air-operated double diaphragm pumps work by compressed air back-and-forth driving two diaphragms in two pumping chambers. One chamber draws in the liquid while the other expels it. This is called the "ballotini" effect, and it is a type of positive displacement pump. Diaphragm transfer pumps are used to handle fluids from place to place in the food industry, haz-mat industry, and oil/gas industry, as well as in the construction industry.

Specifications for Edon pumps vary depending on the type of pump being used. Below are some of the specifications to keep in mind.

Proper pump maintenance can easily prevent breakdowns and extend the pump's lifespan. Below are some helpful maintenance tips for a pump.

Construction and Infrastructure:

In the construction and infrastructure industry, Edon concrete pumps are commonly used to transport freshly mixed concrete from the ground level to various points of construction sites. Edon water pumps, on the other hand, are commonly used for dewatering, construction site water management, and providing potable water supply or sanitation services.

Industrial Processes:

Edon industrial pumps are widely used in manufacturing processes to convey chemicals, lubricants, coolants, and other fluids. They are also used in the mining industry for ore slurry handling, mine dewatering, and cooling systems.

Agriculture and Irrigation:

Farmers use Edon water pumps to irrigate crops, manage drainage systems, and maintain water supply for livestock and farm operations.

Oil and Gas:

Edon pumps play a crucial role in the oil and gas industry. They are used for fluid transfer, including crude oil,water (used for enhanced oil recovery), chemicals, and additives. They are commonly used in upstream oil extraction, offshore platforms, refineries, and petrochemical facilities.

Transportation and Logistics:

In the logistics and transportation industry, Edon pumps are used to handle and transfer various liquids and fluids, such as fuels, lubricants, and chemicals, in warehouses, distribution centers, and ports.

Environmental and Municipal Services:

Edon pumps are widely used in environmental protection and municipal services. They are used for wastewater treatment, solid waste leachate treatment, landfill gas extraction, and air pollution control. Additionally, Edon pumps are also used for municipal water supply, sewage treatment, and stormwater drainage.

Food and Beverage Processing:

Edon pumps are used to handle various types of food and beverage fluids, ingredients, and cleaning solutions. They are also used for sanitary transfer and filing operations in processing plants.

When selecting a suitable industrial pump for a specific application, it is essential to consider the following factors:

Fluid Characteristics

It is imperative to consider the specific features of the fluids that the pump will be handling, such as viscosity, temperature, density, chemical composition, and whether there are any solids.

Required Capacity and Pressure

Determine the flow rate and pressure required for the application. The capacity is typically measured in liters per minute (L/min) or gallons per minute (GPM), while the pressure is usually measured in pounds per square inch (PSI) or bar.

System Design

Consider the design of the system that the pump will be a part of, including the piping configuration, any valves or filters, and the available space for the pump.

Operating Environment

The environment where the pump will be installed is also an important consideration. Things like atmospheric corrosion, temperature/humidity fluctuations, vacuum pressure, and exposure to water have to be taken into consideration. This will help determine whether the pump needs to be explosion-proof or watertight.

Budget

The initial purchase cost and ongoing operating expenses (energy costs, maintenance, etc.)

Q1: Which pump is used for high flow rate?

A1: Centrifugal pumps are commonly used for applications requiring a high flow rate.

Q2: What are the two main types of Edon pumps?

A2: The two main types of Edon pumps are centrifugal Edon pumps and positive displacement pumps.

Q3: Can industrial pumps be repaired?

A3: Yes, industrial pumps can be repaired, depending on their condition and the availability of replacement parts.

Q4: What type of pump is most widely used?

A4: The centrifugal pump is the most widely used industrial pump.

Q5: What is the biggest pump in the world?

A5: The biggest pump in the world is the KSB Tara, designed for the transportation of sewage and industrial wastewater.