(499 products available)

Dumbbell sampling machines are essential tools in the realm of material testing, specifically designed to prepare test specimens for tensile tests. These machines are adept at cutting precise dumbbell-shaped samples, which are then subjected to various stress tests to evaluate material properties.

The applications of dumbbell sampling machines are diverse, catering to industries ranging from plastics to textiles. These machines are crucial for quality control laboratories, research and development departments, and manufacturing entities focused on material strength and durability.

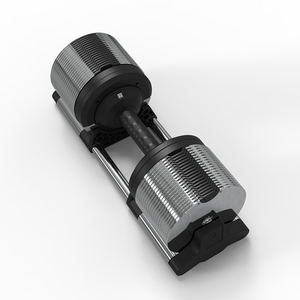

A dumbbell sampling machine is equipped with features that ensure the accuracy and repeatability of sample preparation. These include precision blades and advanced control systems that dictate the dimensions of the cut, adhering to international testing standards. The robust construction of these machines ensures longevity and consistent performance.

The construction of a dumbbell sampling machine typically involves high-grade metals that resist wear and tear, ensuring that the integrity of the sample cut is never compromised. The design is often compact, allowing for efficient use of laboratory space.

Utilizing a dumbbell sampling machine in material testing brings forth numerous advantages, such as enhanced precision in sample preparation, which is critical for accurate test results. The automation of the sampling process reduces the potential for human error and increases the throughput of testing procedures.

When selecting a dumbbell sampling machine, it is important to consider the specific requirements of the material testing to be conducted. Factors such as sample thickness, material type, and the desired standard of the specimen shape should guide the selection process.