All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2326 products available)

A DPF filter cleaning machine is a modern tool designed to clean and maintain diesel particulate filters (DPF). DPF filters trap harmful soot and emissions from diesel engines to reduce environmental pollution. Over time, these filters get clogged, affecting their performance and the engine's efficiency. Traditional cleaning methods, such as using compressed air or back-flushing, are no longer effective or safe for DPFs. Therefore, specialized DPF cleaning machines are now used to remove all trapped soot and debris without damaging the filters.

There are several types of DPF cleaning machines, each with unique features and uses. This section highlights some of the most popular machines:

Ultrasonic DPF cleaning machine:

It uses high-frequency sound waves to produce vibrations in a liquid cleaning solution. This process, known as ultrasonic cavitation, generates microscopic bubbles that collapse and create powerful shock waves. These shock waves dislodge and remove contaminants, such as soot and debris, from the DPF surfaces. The machine can thoroughly clean DPFs without using harsh chemicals or physical abrasion that could damage the filters. Additionally, ultrasonic cleaning is fast and efficient, saving time and labor costs.

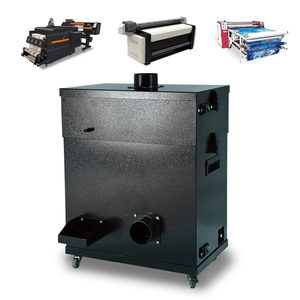

Vacuum DPF cleaning machine:

A DPF filter cleaning machine with a powerful vacuum removes soot and particulate matter trapped in the diesel particulate filter. The machine has a vacuum with high suction power to collect loose particulates during the cleaning process. Some also have multiple filtration stages to prevent the release of fine particles back into the environment. As a result, the machines improve air quality by ensuring the collected particulates are contained within the machine.

Air-powered DPF cleaning machine:

The machine uses compressed air to clean diesel particulate filters. They incorporate air jets and blow-off nozzles that generate high-velocity air streams to dislodge and remove accumulated soot and debris from the filter surfaces. The machines can also remove blockages in the DPF's flow channels by blowing through the entire filter. They are portable and easy to operate.

DPF regeneration machine:

The DPF regeneration cleaning machine mimics the high temperatures achieved during normal engine operation. It uses a heating element to raise the exhaust temperature to the required level. Consequently, all trapped soot and particulates in the DPF oxidize and turn into harmless gases like CO2. The machine also has a control system that monitors the temperature and flow rates to ensure the cleaning process is efficient and safe. Furthermore, it has data logging capabilities that record the cleaning process parameters.

DPF chemical cleaning machine:

The DPF chemical cleaning machine uses specialized cleaning agents to remove accumulated soot and particulate matter from the filters. These cleaning agents are designed to dissolve or disperse the trapped particles, allowing them to be flushed or rinsed out. They are particularly useful for removing stubborn deposits that traditional cleaning methods may not effectively remove. The machines also include a pumping system to circulate the cleaning solution through the DPF and a filtration system to capture the dislodged particles.

There are several DPF cleaning machines available, each with its own specifications. Here are some common specifications of a DPF cleaning machine:

Cleaning Capacity:

The total amount of soot and ash a DPF cleaning machine can clean in a single cleaning cycle is referred to as cleaning capacity. Different machines have different cleaning capacities. The cleaning capacity is measured in grams.

Airflow:

Airflow refers to the total volume of air that moves through the DPF cleaning machine in a minute. It is measured in cubic feet per minute. Machines with higher airflow ratings have more effective cleaning capabilities.

Ultrasonic Frequency:

Some DPF cleaning machines use ultrasonic cleaning technology to remove soot and other deposits. The ultrasonic frequency, measured in kilohertz, determines the cleaning power of the machine. Higher frequencies result in more effective cleaning, especially for delicate filters.

Heating Capacity:

Some DPF cleaning machines have a heating element that warms the cleaning solution or air. Heating capacity is measured in watts or BTUs. Machines with a higher heating capacity can improve the effectiveness of the cleaning process by increasing the temperature.

Vibration Level:

Machines that use vibration to dislodge deposits have their vibration level measured in decibels. The vibration level is an indicator of the cleaning machine's ability to remove stubborn deposits.

It is essential to maintain a DPF cleaning machine regularly to ensure optimal performance and longevity. Here are some general maintenance requirements:

There are several factors that buyers need to consider before purchasing a DPF cleaning machine. These are;

Jobs and DPF types

It is crucial to consider the kinds of DPF jobs intended to be carried out and the types of DPFs that are likely to be encountered. Different DPF cleaning machines are designed for various DPF types and cleaning methods. Some are more suitable for DPFs with ceramic substrates, while others are better for metallic substrates.

Portability

Assess whether portability is essential for the intended DPF cleaning tasks. Some DPF cleaning machines are compact and portable, while others are larger and stationary. If DPF cleaning is required at different locations or in confined spaces, a portable DPF filter cleaning machine would be advantageous.

Budget

Setting a budget before purchasing a DPF cleaning machine is important. DPF machines are available at various prices, so buyers should consider the features, performance, and long-term benefits. Sometimes, opting for a more affordable portable DPF cleaning machine can be advantageous in the long run.

Safety and Environmental Considerations

When choosing a DPF cleaning machine, it is important to consider safety features such as protective equipment and environmental considerations such as emissions and waste disposal. Some DPF cleaning machines have integrated systems for minimal environmental impact and safe operation.

Brand Reputation and Support

It is advisable to research the brand reputation of the DPF cleaning machine and manufacturers. Reliable brands offer quality products and excellent customer support. Additionally, check if spare parts and accessories for the chosen DPF cleaning machine are easily obtainable.

Features and Functionality

When choosing a Dpf filter cleaning machine, consider its features and functions. Look for machines with multiple cleaning options, such as ultrasonic, chemical, or water-based cleaning. Some machines may also have integrated heating systems or advanced filtration technologies to enhance cleaning efficiency. Select a machine that best meets the DPF cleaning requirements and budget.

Here is a step-by-step guide on how to clean DPF using a DPF cleaning machine:

1. Safety Precautions: Before anything else, it's crucial to adhere to safety measures. This entails putting on the necessary safety gear, like gloves and safety glasses, and ensuring that the area is well-ventilated where the DPF cleaning machine will be used.

2. Preparing the Vehicle: Ascertain that the automobile is parked on a level surface and that the parking brake is engaged. Read the manufacturer's instructions to ensure the DPF cleaning machine is compatible with the cleaning machine.

3. Removing the DPF: The first step is to remove the DPF from the exhaust system. This often entails loosening several bolts or clamps. The vehicle's service manual should be consulted for instructions on locating and removing the DPF.

4. Connecting the DPF Cleaning Machine: After installing the DPF, hook up the DPF cleaning machine according to the manufacturer's instructions. This often entails attaching the machine's inlet and outlet ports to correspond with the DPF's exhaust system.

5. Selecting the Cleaning Cycle: Select the appropriate cleaning cycle on the DPF cleaning machine. Depending on the kind of DPF and the cleaning solution being utilized, different cycles may be required.

6. Starting the Cleaning Process: Activate the DPF cleaning machine after double-checking that it is correctly connected and set to the right cleaning cycle. Depending on the model, the machine will use compressed air and a cleaning solution to clean the DPF's interior filters while also injecting the cleaning solution.

7. Monitor the Process: During the cleaning process, keep an eye on the machine's indicators and make sure everything is operating as it should. Follow the manufacturer's instructions for the suggested cleaning time.

8. Disconnecting the DPF Cleaning Machine: After the cleaning cycle is complete, turn off the DPF cleaning machine and carefully disconnect it from the DPF. Make sure there are no leaks or damages by inspecting the cleaning solution.

9. Reinstalling the DPF: Reinstall the DPF in accordance with the manufacturer's instructions. Ensure that all bolts and clamps are properly torqued and that there are no exhaust leaks.

10. Perform a Test Drive: After reinstalling the DPF, perform a test drive to ensure everything is operating as it should. Check the DPF cleaning machine's indicators and make sure there are no error codes or warning signals.

Q1: What is a DPF?

A1: A DPF is a diesel particulate filter. It's a device used in the exhaust system of diesel vehicles to remove soot and particulate matter from the exhaust gases, reducing air pollution.

Q2: What does a DPF filter cleaning machine do?

A2: A DPF filter cleaning machine is used to clean diesel particulate filters that can become clogged with soot over time. DPF cleaning machines remove the accumulated particulate matter from the DPFs, restoring their function and performance.

Q3: Why is it important to clean DPF filters?

A3: Cleaning DPF filters is essential to maintain engine performance, fuel efficiency, and reduce harmful emissions. A clogged DPF can lead to increased fuel consumption, engine performance issues, and potentially costly repairs.

Q4: How often should DPF filters be cleaned?

A4: The frequency of DPF cleaning depends on several factors, including the type of vehicle, driving conditions, and the quality of diesel fuel used. Generally, a professional DPF cleaning is recommended every 50,000 to 100,000 miles or as needed.

Q5: Are DPF cleaning machines safe for all types of vehicles?

A5: Yes, DPF cleaning machines are designed to be safe and effective for all types of diesel vehicles, including cars, trucks, and heavy-duty vehicles. Following the manufacturer's instructions and using the machine correctly is essential to ensure safety and efficiency.