(36277 products available)

The digital temperature display with a sensor is a device that measures and shows the temperature in degrees. It has two main components: the temperature sensor, which detects temperature changes, and the display, which shows the measured temperature. There are several types of digital temperature displays on the market.

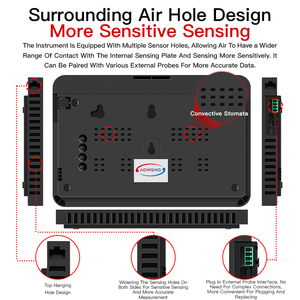

The design of digital temperature displays includes many aspects. They range from aesthetics to functionality and influence the effectiveness of the devices. Business buyers need to pay attention to these aspects when choosing temperature displays.

Digital temperature displays can be used in many different applications and industries.

Food industry

Digital temperature displays are widely used in the food industry, especially in restaurants, catering, and food manufacturing. They are used in cooking equipment like fryers and stoves to ensure the right cooking temperature. Food storage equipment like refrigerators and freezers use digital temperature sensors to ensure food quality. Food delivery vehicles also use these displays to monitor temperatures during transportation. Additionally, food inspection tools such as meat thermometers and candy thermometers utilize these displays to ensure food safety.

Pharmaceutical industry

In the pharmaceutical industry, digital temperature displays are crucial for drug manufacturing, storage, and transportation. They are used in climate control chambers and drug storage cabinets to maintain and monitor temperatures for sensitive drugs, vaccines, and biologics. During the distribution of pharmaceuticals, digital thermometers in delivery vehicles and cargo containers ensure that drugs requiring temperature control are kept within their safe temperature ranges. Moreover, the cold chain monitoring systems used in the transportation of temperature-sensitive pharmaceuticals also rely on these displays to provide real-time temperature data.

Greenhouses and horticulture

In greenhouses and horticulture, digital temperature displays are used to monitor and control the temperature of plants. They are used in heating, ventilation, and air conditioning (HVAC) systems to maintain optimal growing conditions for crops and flowers. Temperature sensors are also used in soil moisture meters to provide data for irrigation systems. Additionally, in aquaponics systems, digital temperature displays are used to monitor water temperatures for both fish and plants.

Industrial applications

Industrially, digital temperature displays are used in process control to monitor and control temperatures in manufacturing. They are used in HVAC systems for building management to maintain comfortable living and working conditions. Temperature sensors are also used in machinery and equipment for performance monitoring. Furthermore, in safety and protection systems, digital thermometers are used to detect overheating and trigger alarms.

Educational institutions and laboratories

In educational institutions, digital temperature displays are used in science classes to teach temperature concepts. Laboratories utilize these displays for various experiments requiring precise temperature measurements. Additionally, weather stations in schools and research institutions use these displays to monitor and record environmental temperature data.

Aviation and automotive industries

In the aviation industry, digital temperature displays are used in cockpit instruments to provide pilots with critical information about aircraft systems. They monitor engine temperatures, airspeed indicator temperatures, and other vital indicators to ensure safe and efficient flight operations. Similarly, in the automotive industry, these displays are used in dashboard instruments to provide drivers with real-time information about vehicle conditions. They indicate engine temperatures, external air temperatures, and other important data to help ensure safe driving.

There are several important factors that one should consider when choosing a digital temperature display with a sensor. By considering these factors, one will be able to choose an appropriate digital temperature display with a sensor that fits one's specific requirements. It is important to consider the type of environment in which the device will be used. If it will be used in harsh conditions, one should opt for a device with a sturdy construction that is resistant to water, dust, and extreme temperatures. The accuracy and range of measurements are also important to consider. One should choose a device that provides precise readings within the desired range. The resolution and calibration of the sensor should also be considered to ensure measurement accuracy.

One should also consider the ease of installation and usage of the device. One should look for clear instructions and user-friendly interfaces that make the device easy to operate. Additionally, one should consider the features and functionality of the device. One should choose a device that has additional features such as data logging, alarm functions, and connectivity options. The power supply and energy efficiency of the device are also important to consider. One should choose a device that has low power consumption, which helps to reduce operating costs. Digital displays can be powered by batteries or mains electricity, so one should select the appropriate power supply mode according to one's needs. Consider the display and readability of the device. One should choose a device that has a clear and easy-to-read display, making it convenient to view measurements.

Lastly, one should also consider the cost and budget of the device. One should choose a device that is cost-effective and meets one's requirements while staying within budget. The brand and after-sales service of the device should also be considered. One should choose a well-known brand's product that provides quality assurance and good after-sales service. By considering these factors comprehensively, one will be able to choose a digital temperature display with a sensor that meets one's specific needs. It is advisable to do some research and compare various products to make an informed decision.

Q1. How does a digital temperature display work?

A1. Digital temperature displays work by measuring the temperature using a thermistor, thermocouple, or RTD. This reading is converted into an electrical signal, which is then processed and displayed on the screen.

Q2. What is the difference between Celsius and Fahrenheit in digital temperature displays?

A2. Celsius and Fahrenheit are two different scales for measuring temperature. Digital temperature displays can show readings in either scale, often switchable depending on user preference.

Q3. How can one calibrate a digital temperature display?

A3. Calibration can be done by comparing the device's readings with a known accurate thermometer and adjusting the display output accordingly, usually through a calibration menu in more advanced devices.

Q4. What factors should be considered when choosing a digital temperature display with a sensor?

A4. Consider accuracy, range, response time, power supply, environmental conditions, and connectivity options to choose a suitable device for specific applications.

Q5. How can one maintain a digital temperature display?

A5. Keep the device clean and free from dust; check batteries regularly for power supply maintenance and ensure connections are secure for optimal performance.