All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(290 products available)

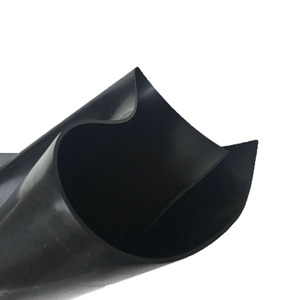

The material is known as diamond plate roll rubber matting and comes in various types. These types depend on the setting in which they will be used. These mats provide traction and comfort underfoot while preventing slips in wet or dry areas.

Vinyl diamond plate mats use vinyl diamond plate patterns for easy maintenance and cleaning. The matrix is stain-resistant and available in colors that improve visibility. These qualities make it popular in kitchens, workshops, and retail environments.

Nitrile rubber mats handle oils, chemicals, and grease. They feature a textured diamond plate surface that ensures excellent grip. Nitrile mats are ideal for automotive workshops and manufacturing plants that frequently deal with such conditions. This is because they resist wear and tear associated with exposure to such substances.

Plain rubber mats feature a solid, non-slip rubber surface. They are suitable for general-purpose use where basic anti-slip properties are required. These mats are often used in entryways, gyms, and industrial areas with minimal exposure to chemicals.

Heavy-duty rubber mats are designed for extremely high-traffic areas and harsh conditions. Their reinforced diamond plate pattern rubber is thicker and more durable. These mats withstand heavy machinery, fork trucks, or large foot traffic volumes. Many of these mats also offer increased noise-dampening and anti-fatigue properties.

Selecting the proper diamond plate roll rubber matting requires careful consideration of several factors, including the intended application, environment, and required durability. There are also other factors like thickness, texture, and size, and they should be considered.

Knowing the primary reason for choosing such mats will influence the decision significantly. For instance, mats in industrial settings require materials resistant to chemicals and oils. Mats meant for commercial use should be attractive and easy to clean, whereas mats used on manufacturing plants' floors should be durable and non-slip.

The environment in which the matting will be installed is another vital point to consider. Outdoor environments require mats that can withstand UV rays and extreme weather conditions. On the other hand, mats that will be exposed to moisture regularly should have excellent drainage capabilities to avoid mold and mildew growth.

Durability is vital for instances having high traffic volumes or with heavy machinery. The materials should also be resistant to wear and tear, and they should also be highly flexible. In terms of thickness, more extended uses require thicker mats. Such mats provide better wear resistance, hence making them ideal for heavy-duty applications.

Some diamond plate rubber mats require more maintenance than others. Mats used in commercial kitchens or workshops should be easy to clean and stain-resistant. Mats with extended maintenance requirements should also have quick and easy cleaning processes available.

Safety is one of the core reasons for installing these mats. Therefore, it's essential to examine the mat's slip resistance besides its thickness and texture. For instance, deeper patterns provide better traction in slippery conditions, while more prominent patterns enhance visibility. This makes them suitable for wet and dry environments.

The specification considerations and care requirements sustain diamond plate roll rubber matting's performance, durability, and appearance. Some of these specifications include:

Maintenance of diamond plate rubber matting is vital for its durability. Proper maintenance is also important for its cleanliness and overall hygiene. One of the most important maintenance requirements considers the cleaning methods that should be used. Usually, the type of cleaning agent used should be suitable for the kind of material. For instance, mild detergents are good for vinyl mats, while nitrile soaps are good for nitrile mats.

In addition to this, regular inspections of the mats should be done to check for damages. This helps in identifying repairs needed before the damage worsens and becomes more costly. Mats that wear out, especially in high traffic areas, should be replaced promptly to maintain safety and functionality.

To avoid such damages, the matting should be placed in suitable conditions where extreme heat or direct sunlight can be avoided. Mats exposed to such conditions frequently should be UV-resistant designs to prevent cracking or fading.

Diamond plate rubber matting is a versatile and practical flooring solution that combines safety, durability, and comfort. Its unique diamond pattern provides excellent traction in slippery conditions, making it suitable for various applications ranging from industrial to commercial and residential settings. When selecting the right matting, one should consider factors such as purpose, environment, and required thickness to ensure optimal performance. Regular maintenance, including proper cleaning and inspection, will extend the life of the mats, keeping them functional and visually appealing. With its unique features and customizable options, diamond plate rubber matting continues to be a popular choice for enhancing safety and aesthetics in multiple environments.

Several factors can help make this decision. To begin with, frequent cracking or fading means the matting has been exposed to external elements over time. If the matting has become very smooth and shiny, it means it no longer provides good traction, which is one of its main purposes. Also, if the mat has started breaking down, such as having small pieces of it coming off, or if there are holes, it means it is time for a replacement. Vertical rubber mats like these are not meant to last forever. Hence, one has to be keen when the materials reach their retirement age.

Yes, both the thickness and length of the rolls influence their performance significantly. As earlier mentioned, rolls can range in thickness from 1/16 inch to 1/2 inch and even more in the case of some products. Usually, the higher the thickness, the more durable it becomes. Longer rolls cover large areas without seams.

However, shorter rolls are more manageable in installation. More extended rolls also take more time to replace if damaged. The thickness and length combination should thus suit the particular application requirements.

Yes, manufacturers produce flexible diamond plate roll rubber matting. Users can have them customized according to specific application requirements. Color, pattern depth, material composition, and roll size can all be customized. Users should just ensure they deal with manufacturers who have the technology to provide the customization.

This largely depends on the conditions and the traffic to which it is exposed. Cleaning should be done regularly, of course. The cleaning should be as frequent as needed in high-traffic areas where it comes into contact with dirt, grease, or spills. They should also be cleaned after seasonal changes, like before winter, if they will get water and snow.

On the other hand, low-traffic areas like offices can be left for less frequent cleaning. Also, exterior mats exposed to debris and environmental elements should be cleaned more often.