(925 products available)

A deep drawing lamp reflector is a crucial component in the design of metal parts. Deep drawing is a manufacturing process where a metal disc is converted into a deeper part than the drawing blank. Lamp reflectors are used in this process to provide light that helps in heating the metal blank. This heating is important for deep drawing as it makes the metal malleable enough to be shaped into the desired part. Here are the various types of deep-drawing lamp reflectors.

Aluminum Reflectors

These reflectors are made of aluminum, which is a lightweight and robust material. They are usually used in applications that require high durability and strength. Aluminum reflectors can withstand harsh conditions and are often used in industrial deep drawing processes.

Plastic Reflectors

Plastic reflectors are lightweight and cost-effective. They are suitable for applications that require non-conductive materials. However, they may not offer the same level of durability and heat resistance as aluminum reflectors.

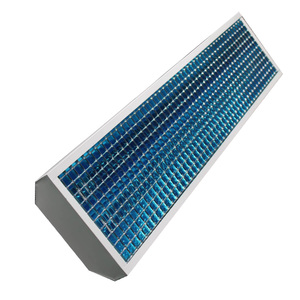

Polished Metal Reflectors

These reflectors are made of metal that has been polished to a high degree of smoothness. This increases the amount of light that is reflected and is used in applications that require intense lighting. They are suitable for use in deep drawing processes where high visibility is essential.

Vacuum Metalized Reflectors

These reflectors are made by depositing a thin layer of metal onto a plastic substrate under vacuum conditions. This process creates a durable and lightweight reflector with high reflectivity. Vacuum metalized reflectors are used in applications where weight savings and high performance are essential.

Textured Reflectors

Textured reflectors have a surface pattern that diffuses light. This produces a more even light distribution, and they are used in deep drawing applications that require consistent lighting across the area. Textured reflectors can be made from aluminum or plastic.

Clear Glass Reflectors

These reflectors are made from clear glass. They provide high light transmission and are used in applications that require high levels of illumination. However, they are more fragile and less versatile than other types of reflectors.

Deep drawing lamp reflectors are essential components of metal forming and deep drawing processes. These reflectors have specific functions and features that enhance lighting efficiency and metalworking.

Uniform Light Distribution

Deep drawing lamp reflectors ensure that there is even light distribution across the work area. This uniformity minimizes shadows and creates a clear view of the metal sheets. Uniform light helps operators monitor the drawing process and prevents defects.

Concentration of Light

The design of these deep drawing lamp reflectors allows the direction of light towards specific areas. This concentration results in sufficient illumination where it is most needed. For example, in the case of areas of the metal sheet that are about to be drawn. The concentrated light increases visibility and control over the deep drawing process.

High Temperature Resistance

Deep drawing processes involve the application of heat. Lamp reflectors for these applications are constructed with materials that can withstand high temperatures. For example, aluminum and steel. These materials resist warping and ensure durability.

High Light Reflectivity

These reflectors are made with materials that have a high light reflectivity coefficient. For example, polished aluminum and stainless steel. The high reflectivity allows for maximum light output, enhancing the efficiency of the drawing lamp.

Durability

Durability is an important feature of deep drawing lamp reflectors. These reflectors are constructed with materials that can withstand wear and tear. They also resist scratches and corrosion. This ensures that the reflectors maintain optimum performance over a long period of time.

Adjustability

Some deep drawing lamp reflectors have adjustable components. For example, dimmers and light angles. This adjustability allows operators to customize the lighting conditions depending on the specific requirements of the deep drawing process. This improves the efficiency of the operation.

Heat Dissipation

Deep drawing lamp reflectors are designed to manage and dissipate heat that is generated. For example, by using fins or ribbed structures. Effective heat dissipation prevents overheating of the lamp and ensures continuous operation.

Deep-drawn lamp reflectors are widely applicable in various industries. Their design allows for the efficient distribution of light for different uses. Some common application scenarios include:

When choosing a lamp reflector, it is important to consider a number of factors in order to purchase an ideal product. Here are some of them:

Consider The Type Of Metal Used

It is important to choose a lamp reflector that will be durable and last a long time. The metal used to make the reflector has to be corrosion resistant and conductive in order to provide optimum light. Also, choose a material that is easy to clean and maintain.

The Size Of The Lamp And The Size Of The Reflector

The size of the lamp is very important when choosing a reflector. A small lamp will need a small reflector, and a large lamp will need a large reflector in order to work correctly. Also, the depth of the reflector will impact how light is distributed. A deeper reflector is good for focusing light on a certain area, while a shallower reflector spreads the light more evenly.

The Type Of Coating

The coating on the lamp reflector plays an important part in how light is produced. A coating that is highly polished increases brightness, while a white coating increases light that is more diffuse. The coating has to be durable and withstand high temperatures.

The Type Of Lamp

Different lamps have different needs when it comes to reflectors. For example, LED lamps need special LED reflectors to work efficiently, while halogen lamps work well with halogen reflectors. The type of lamp used will determine the kind of reflector needed.

Wattage And Voltage

The wattage and voltage of the lamp will impact the choice of reflector. Lamps with high wattage need reflectors that can withstand high levels of heat, while low wattage lamps can use reflectors made of different materials.

Customization

In some cases, a custom lamp reflector is needed. This involves taking measurements and working closely with the manufacturers to come up with a reflector that will meet all the requirements of the lamp.

Q1: What are the key features of a deep-drawing lamp reflector?

A1: Key features include durability, high thermal resistance, corrosion resistance, high reflectivity, and a uniform and deep shape.

Q2: What are the common materials used in deep-drawing lamp reflectors?

A2: The common materials include glass, aluminum, and stainless steel. These materials are preferred due to their high temperature and heat resistance.

Q3: What is the minimum order quantity for deep-drawing lamp reflectors?

A3: The minimum order quantity varies depending on the manufacturer. Some manufacturers have a MOQ of 100 pieces, while others have 500 pieces or more. It is advisable to check the MOQ provided by the manufacturer before placing an order.

Q4: Are deep-drawing lamp reflectors customizable?

A4: Yes, some manufacturers offer customizable deep-drawing lamp reflectors. Customization may include the size, material, and shape of the reflectors. It may also include the addition of brand logos on the reflectors.

Q5: How can buyers find reliable deep drawing lamp reflector suppliers on Alibaba.com?

A5: Buyers can find reliable suppliers by checking the supplier's ratings and reviews, verifying business licenses, and comparing quotes from different suppliers. They can also communicate with the supplier to determine their level of professionalism.