All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(4234 products available)

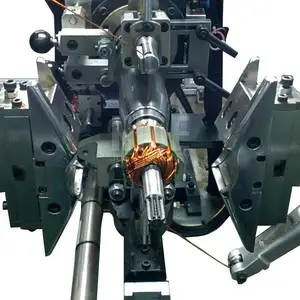

A DC motor winding machine is a precise and automated device designed to wind coils and stators for DC motors. These machines are equipped with advanced mechanisms and controls to facilitate the winding process, ensuring accuracy and efficiency. A BLDC motor winding machine provides a comprehensive solution for the production of brushless DC motors, offering consistent and high-quality windings that are essential for the motor's performance and reliability.

A DC machine winding is used for winding coils and stators of DC motors, which are essential components in various industries. DC motors are commonly employed in applications requiring precise speed control, such as robotics, automation, and electric vehicles. The winding machine is utilized to create the coil configurations within the motor, determining its performance characteristics.

For example, in the automotive sector, these machines play a crucial role in the manufacture of electric vehicle components. They are utilized to wind the stators of DC motors, contributing to the efficient and reliable operation of the vehicle's propulsion system. In the industrial automation sector, DC motor winding machines are used to produce motors for machinery and equipment, enabling precise control and motion in manufacturing processes. Additionally, in the renewable energy sector, such as wind and solar power, these machines contribute to the production of specialized DC motors used in generators and tracking systems.

The BLDC winding machine operates through a series of automated processes to ensure the precise and efficient winding of coils and stators. It consists of a spindle or rotating platform where the winding is executed. The machine is equipped with tensioning devices that maintain the appropriate tension on the wire during winding. Additionally, it may have wire guiding mechanisms to ensure the uniform distribution of wire throughout the winding process.

The BLDC stator winding machine incorporates sophisticated controls that allow for the customization of winding parameters such as the number of turns and wire gauge. These parameters are crucial in determining the motor's performance characteristics. The machine accurately winds the wire around the designated components, creating the required coil configuration. Furthermore, the machine can perform various winding patterns, including lap and concentric windings, based on the motor design requirements.

DC motor winding machines offer significant advantages in terms of efficiency, precision, and versatility. Their automated operation reduces manual labor, streamlining the production process and increasing overall efficiency. By ensuring precise and consistent winding, these machines contribute to the high-quality and reliable performance of DC motors. This level of precision is crucial in applications where even minor deviations can impact motor efficiency and longevity.

The versatility of DC motor winding machines allows for the customization of winding parameters to meet specific design requirements. This adaptability is essential in industries where motor performance is tailored to unique applications. Moreover, the use of advanced controls and technology in these machines enhances productivity and reduces the risk of errors. By integrating sophisticated features, DC motor winding machines contribute to the advancement of motor manufacturing practices, meeting the evolving demands of various industries.