Types of DC Motor Starters

A DC motor starter is an electrical device designed to start and control the speed and torque of direct current (DC) electric motors. It provides a safe and efficient way to manage motor operations, protecting both the motor and connected equipment from damage caused by high inrush currents during startup.

Key Benefits of DC Motor Starters

DC motor starters find applications in various industries where precise motor control is essential, including manufacturing, material handling, transportation, and more. They're particularly valuable in tasks requiring consistent and reliable motor performance, such as conveyor systems, hoisting equipment, printing machines, and packaging machinery.

Industry Insight: DC motor starters increase operational efficiency, reduce wear and tear on equipment, and improve overall system performance by seamlessly integrating with control systems, enabling automation and remote control capabilities.

Common DC Motor Starter Types

Switch Starter

A basic starting configuration that uses a switch or set of contacts to connect or disconnect the motor from the power supply.

Best for: Small DC motors in power tools, fans, or small machinery

Advantage: Simple and cost-effective starting method

Limitation: May not provide smooth starting or stopping for larger applications

Relay Starter

Employs one or more relays to control the motor's connection to the power supply, acting as electrically operated switches for remote control.

Best for: Industrial automation or applications requiring safety interlocks

Advantage: More control and safety features than switch starters

Limitation: More complex circuit design than basic switch starters

Push Button Starter

A control circuit using push buttons to start or stop the motor, typically with momentary contact buttons and latching contacts.

Best for: Machine tools, conveyors, and production lines requiring operator control

Advantage: Precise control over motor operation, including starting, stopping, and speed adjustment

Limitation: Requires operator presence for manual control

Manual Starter

A DC motor starter requiring manual operation via rotary switch, toggle switch, or lever to control the motor's electrical circuit.

Best for: Small machinery, fans, or ventilation systems where precise control isn't critical

Advantage: Simple, reliable, and cost-effective solution

Limitation: Less convenient and lacks automation compared to other starter types

| Starter Type | Complexity | Cost | Control Precision | Best Applications |

|---|---|---|---|---|

| Switch Starter | Low | Low | Basic | Small motors, power tools |

| Relay Starter | Medium | Medium | Good | Industrial automation, remote control |

| Push Button Starter | Medium | Medium | High | Production lines, machine tools |

| Manual Starter | Low | Low | Basic | Small machinery, ventilation systems |

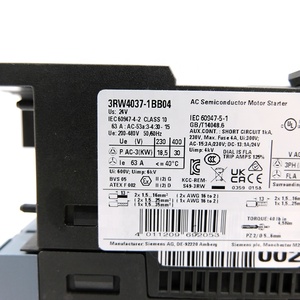

Specifications and Maintenance of DC Motor Starters

Key Specifications

| Specification | Description | Typical Range | Importance |

|---|---|---|---|

| Current Rating | Should be equal to or greater than motor full-load current | 10A - 500A+ | Critical - Provides overload protection |

| Voltage Rating | Should match motor supply voltage | 12V - 600V+ | Critical - Ensures proper operation |

| Wiring Connections | Marked terminals for electrical connections | Bolts, screw terminals, plug-in connectors | High - Enables proper installation |

| Control Voltage | Voltage applied to control circuit (typically lower than supply voltage) | 24V - 110V | Medium - Determines control system compatibility |

| Size and Mounting | Physical dimensions and mounting options | Panel, DIN-rail, or surface-mounted | Medium - Affects installation requirements |

Selection Tip: Always choose a DC motor starter with a current rating at least 25% higher than your motor's full-load current to allow for startup surges and occasional overloads while maintaining a safety margin.

Essential Maintenance Practices

Proper maintenance of DC motor starters is crucial for ensuring reliability, extending operational life, and preventing costly downtime. Implement these key maintenance practices:

Regular Inspection

Check for wear, damage, and loose connections. Inspect contacts, coils, terminals, and enclosures for signs of deterioration or overheating.

Frequency: Monthly or according to usage intensity

Tools needed: Inspection mirror, flashlight, thermal camera (optional)

Cleaning

Remove dust, dirt, and debris using a clean cloth or brush. Clean contacts and electrical connections with appropriate cleaning solutions.

Frequency: Quarterly or as environmental conditions dictate

Tools needed: Compressed air (low pressure), electrical contact cleaner, lint-free cloths

Lubrication

Apply manufacturer-recommended lubricant to moving parts such as contacts and mechanisms to reduce friction and extend component lifespan.

Frequency: Semi-annually or per manufacturer guidelines

Materials needed: Appropriate electrical contact lubricant, precision applicator

Testing

Perform functional tests to verify proper operation of the control circuit, overcurrent protection, and interlocks to ensure system safety and performance.

Frequency: Annually or after any system modification

Equipment needed: Multimeter, insulation tester, appropriate test loads

Safety Warning: Always disconnect power and follow proper lockout/tagout procedures before performing any maintenance on DC motor starters. Verify power is off using appropriate testing equipment before touching any components.

How to Choose DC Motor Starters

Selecting the right DC motor starter is crucial for ensuring optimal performance, safety, and longevity of your motor system. Consider these essential factors when making your decision:

Current Rating

Choose a starter with a current rating that exceeds your motor's full-load current (FLC).

Recommendation: Select a starter rated at 125% of FLC for normal operations and 150% for applications with frequent overloads.

Why it matters: Prevents starter damage and ensures proper motor protection during high-current situations.

Voltage Rating

The starter's voltage rating must match your motor's operating voltage to ensure compatibility and safety.

Recommendation: Verify exact voltage specifications rather than approximate ranges.

Why it matters: Improper voltage matching can lead to premature component failure or inadequate motor performance.

Size and Installation

Consider the physical dimensions and mounting options for your specific application environment.

Recommendation: Choose compact, easily mounted starters that simplify wiring and maintenance access.

Why it matters: Proper physical integration ensures easier installation, maintenance, and space optimization.

Control Voltage

Ensure the starter's control voltage is compatible with your existing control system.

Common options: 24V, 48V, or 110V control circuits

Why it matters: Mismatched control voltages may require additional components or prevent integration with existing systems.

Protection Features

Evaluate the safety and protection mechanisms included with the starter.

Key features: Overload protection, short circuit protection, under voltage protection

Why it matters: Comprehensive protection features safeguard both the motor and starter from damage, increasing system reliability and lifespan.

Starter Type

Select the appropriate starter type based on your application requirements and control needs.

Options: Manual, semi-automatic, or fully automatic starters

Why it matters: The starter type determines the level of operator intervention required and the flexibility of your motor control system.

Expert Advice: When selecting a DC motor starter, consider not only your current requirements but also potential future needs. Choosing a starter with slightly higher ratings and more features than immediately necessary can accommodate system expansions and prevent premature replacements.

| Selection Factor | What to Look For | Common Mistakes to Avoid |

|---|---|---|

| Current Rating | 125-150% of motor FLC | Using exact motor FLC without safety margin |

| Voltage Compatibility | Exact match with motor voltage | Assuming small voltage differences are acceptable |

| Environment Suitability | Appropriate IP rating for operating conditions | Ignoring temperature, dust, or moisture factors |

| Control Requirements | Features matching operational needs | Over-specifying features that won't be utilized |

| Quality & Reliability | Reputable manufacturers, warranty terms | Choosing solely based on lowest price |

How to DIY and Replace DC Motor Starters

Replacing a DC motor starter can be a straightforward process when approached methodically with proper safety precautions. Follow this step-by-step guide for a successful installation:

Safety First: Working with electrical components poses serious safety risks. If you're not confident in your abilities or knowledge, consult a qualified electrician. Always follow local electrical codes and regulations.

Ensure the power supply to the motor is completely disconnected. Use a voltage tester to verify there is no power before proceeding. Follow proper lockout/tagout procedures if applicable in your workplace.

Take clear photos or make detailed diagrams of the existing starter's wiring connections. Label all wires if they aren't already identified. This documentation will be crucial for correctly wiring the new starter.

Carefully disconnect all wires from the old starter. Keep track of which wire connects to which terminal. Use labels if necessary to avoid confusion during reassembly.

Unscrew or unbolt the old starter from its mounting location. Note the orientation and mounting position for installing the new unit.

Mount the new DC motor starter in the same position as the old one. Ensure it is securely fastened to prevent vibration and movement during operation.

Connect all wires to the new starter following your documentation from Step 2. Double-check each connection against your diagram or photos to prevent errors.

Before restoring power, verify all connections are secure and correct. Check for loose terminals, exposed wires, or any signs of potential problems.

Restore power and test the motor operation at minimal load if possible. Observe for proper starter function, unusual noises, or other abnormalities.

Installation Tip: When installing the new starter, ensure adequate clearance around the unit for heat dissipation and maintenance access. Poor ventilation can lead to overheating and premature component failure.

| Common Issue | Possible Cause | Solution |

|---|---|---|

| Motor fails to start | Incorrect wiring, blown fuse, or tripped protection | Verify wiring connections, check fuses and reset protection devices |

| Motor starts but quickly stops | Overload protection activating too quickly | Check overload settings and motor load conditions |

| Starter makes unusual noise | Loose components or contacts | Tighten all connections and verify proper mounting |

| Overheating of starter | Inadequate ventilation or undersized starter | Ensure proper clearance around unit, verify starter rating |

Frequently Asked Questions

A DC motor starter is an electrical device used to start and control direct current (DC) motors. It regulates the flow of current to the motor, providing smooth acceleration and preventing damage to the motor and connected equipment. These devices incorporate various control and protection features to ensure safe and efficient motor operation across different applications.

A DC motor starter is necessary to control the starting process of DC motors and prevent sudden inrush currents that can cause mechanical stress or electrical faults. During startup, DC motors can draw 5-8 times their normal operating current, which can damage the motor windings, trip circuit protection devices, or cause voltage dips in the power supply. Additionally, DC motor starters provide essential features like overload protection, speed control, and safe stopping capabilities, all of which enhance the motor's reliability, performance, and operational safety.

A DC motor starter works by controlling the current flow to the motor using specific electrical components and circuits. During the start-up phase, the starter gradually increases the current by introducing resistance into the armature circuit and then progressively removing it as the motor accelerates. This controlled ramp-up prevents the mechanical shock that would occur with direct connection to power. The starter monitors current levels throughout operation, providing protection against overloads and other fault conditions. Most modern DC starters also incorporate electronic control circuits that allow for precise speed control, soft starting capabilities, and integration with automated systems.

Using a DC motor starter offers numerous benefits, including extended motor lifespan through reduced mechanical stress during startup and shutdown cycles. These starters improve energy efficiency by optimizing motor performance and providing better control over motor speed and torque. The built-in protection features safeguard both the motor and connected equipment from damage due to electrical faults, overloads, or abnormal operating conditions. Additionally, advanced DC motor starters enable precise speed control, smooth acceleration profiles, and integration with automated control systems, enhancing overall system functionality and operational flexibility.

DC motor starters come in several variations to suit different applications and requirements. The main types include switch starters (simple on/off control for small motors), relay starters (using electromagnetic relays for remote operation), push-button starters (offering operator interface with momentary contacts), and manual starters (requiring physical operator intervention). More advanced types include electronic soft starters (providing gradual voltage ramp-up) and microprocessor-controlled starters (offering programmable features and system integration). Each type offers different control capabilities, protection features, and complexity levels, making them suitable for various industrial, commercial, and specialized applications.