(16787 products available)

![[JT-MS1100]Solid Ink Roll <strong>Coder</strong> Expiry <strong>Date</strong> Stamping Coding Machine Batch EXP MFG Code Printing Machine with CE Certificate](http://s.alicdn.com/@sc04/kf/H1d0450148db54f09ba8147b6007c682dC.jpg_300x300.jpg)

![[JT-MS1100]Solid Ink Roll <strong>Coder</strong> Expiry <strong>Date</strong> Stamping Coding Machine Batch EXP MFG Code Printing Machine with CE Certificate](http://s.alicdn.com/@sc04/kf/H2806e84843544e0194592bfa6b376b6eJ.jpg_300x300.jpg)

![[JT-MS1100]Solid Ink Roll <strong>Coder</strong> Expiry <strong>Date</strong> Stamping Coding Machine Batch EXP MFG Code Printing Machine with CE Certificate](http://s.alicdn.com/@sc04/kf/H1a163587d6994f72976a598646287df0e.jpg_300x300.jpg)

![[JT-MS1100]Solid Ink Roll <strong>Coder</strong> Expiry <strong>Date</strong> Stamping Coding Machine Batch EXP MFG Code Printing Machine with CE Certificate](http://s.alicdn.com/@sc04/kf/H935c94eca2ec46da84a82f939cfd09e3U.jpg_300x300.jpg)

![[JT-MS1100]Solid Ink Roll <strong>Coder</strong> Expiry <strong>Date</strong> Stamping Coding Machine Batch EXP MFG Code Printing Machine with CE Certificate](http://s.alicdn.com/@sc04/kf/Hc2f0b6feac4f4c6eb7083bf4059648094.jpg_300x300.jpg)

![[JT-MS1100]Solid Ink Roll <strong>Coder</strong> Expiry <strong>Date</strong> Stamping Coding Machine Batch EXP MFG Code Printing Machine with CE Certificate](http://s.alicdn.com/@sc04/kf/H4a68f5ae7d614b079a61c3de53ee6e4dY.jpg_300x300.jpg)

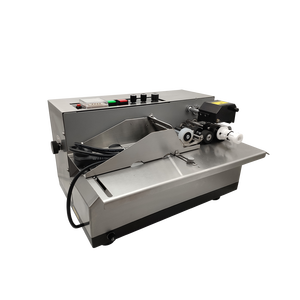

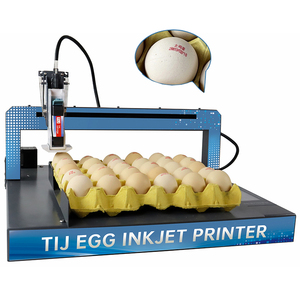

Date coders are essential machines used in various industries to print manufacturing dates, expiration dates, and batch codes on products. These machines are crucial for ensuring product traceability, quality control, and compliance with regulations. Date coders come in different types and configurations to meet the specific needs of businesses.

There are several types of date coders available in the market, including handheld date coders, inline date coders, and automatic date coding machines. Handheld date coders are portable and suitable for small-scale operations, while inline date coders are integrated into production lines for continuous coding. Automatic date coding machines are ideal for high-volume production environments.

When considering a date coding machine, important technical specifications to look for include printing speed, printing resolution, type of printing technology (such as inkjet), compatibility with different surfaces, and ease of integration with existing production lines. Additionally, the ability to support various languages and fonts can be beneficial for businesses operating in global markets.

The features of modern date coders have evolved to enhance efficiency and accuracy in coding processes. Some advanced features include touchscreen interfaces for easy operation, automatic date adjustment, self-cleaning printheads, and connectivity options for data transfer and synchronization with other equipment.

Integrating date coders into production processes offers several advantages, such as reducing human error in date coding, ensuring consistent and legible prints, improving productivity by automating coding tasks, and facilitating quick changeovers between different products or date formats. These advantages contribute to overall operational efficiency and product quality.

Date coders find applications in various industries, including food and beverage, pharmaceuticals, cosmetics, and electronics. In the food industry, date coders are used to mark expiration dates and lot numbers on packaging, ensuring food safety and compliance with labeling requirements. Pharmaceutical companies rely on date coders to imprint manufacturing dates and barcodes on drug packaging for track and trace purposes.

When selecting a date coding machine for your business, consider factors such as production volume, coding requirements, available space for installation, maintenance needs, and budget constraints. It’s essential to choose a date coder that aligns with your production goals and quality standards to optimize operational processes.

Proper maintenance of date coders is crucial to ensure consistent performance and longevity of the equipment. Regular cleaning of printheads, replacing ink cartridges or fluids as needed, and conducting preventive maintenance tasks according to the manufacturer's guidelines can help prevent downtime and costly repairs. Additionally, training operators on machine usage and maintenance practices is essential for maximizing the efficiency of date coders.