All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

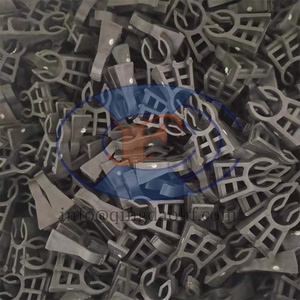

(7387 products available)

Custom wheel adapters and spacers are crucial components in the automotive industry. They are designed to enhance vehicle performance and aesthetics. Understanding the types of custom wheel adapters and spacers is essential for businesses.

Custom wheel adapters and spacers are manufactured in various specifications to accommodate different vehicle models and wheel sizes. Here are some general specifications to expect:

Material

Custom wheel spacers and adapters can be manufactured from different materials, each with advantages. One of the most common materials is aluminum. Aluminum is lightweight and offers good corrosion resistance. Manufacturers also make these components from carbon steel and forged steel. Steel spacers and adapters are more durable and suitable for heavy-duty applications.

Thickness

Wheel spacers come in various thicknesses depending on the intended purpose. The thickness of spacers can range from 3mm to more than 30mm. A 30mm spacer is suitable for customizing a truck's wheel so that it can fit wider tires for off-road purposes. Adapters also have varying thicknesses. The thickness of wheel adapters can range from 10mm to 50mm. Thicker adapters are ideal for sports cars where the need for speed is the order of the day.

Size

Custom wheel spacers and adapters come in various sizes to fit different wheel and hub diameters. They are measured in terms of bolt pattern, which is the arrangement of lug nuts on the wheel. For example, a spacer with a 5x114.3 bolt pattern has 5 holes arranged in a circle with a diameter of 114.3mm. Some common sizes include 4x100, 5x100, 5x114.3, and 6x139.7.

Surface Finish

Custom wheel adapters and spacers can have different surface finishes. Anodizing is a common surface treatment for aluminum adapters and spacers. This process enhances the corrosion resistance of the material while also improving its appearance. Manufacturers may also apply a zinc coating to steel spacers and adapters. Zinc coating protects the steel from rusting.

Maintaining custom wheel spacers and adapters is important to ensure safety and enhance their lifespan. Here are some maintenance tips:

Choosing custom wheel adapters and spacers can be pretty challenging considering the numerous options available. Here are some tips to guide businesses when selecting custom wheel adapters and spacers:

Understanding Offset and Fitment

Offset is the distance between the wheel's mounting surface and its centerline. It affects the wheel's position in relation to the vehicle's body and suspension. A positive offset pushes the wheel closer to the vehicle, while a negative offset extends it outward. Proper offset is crucial for stability, handling, and avoiding clearance issues.

Material Matters

Custom wheel adapters and spacers are often manufactured with aluminum, steel, and titanium. Each of these materials has its advantages. Aluminum is lightweight and resistant to corrosion, making it a popular choice for racing and performance applications. Steel is more robust and durable, making it suitable for off-road and heavy-duty use. Titanium offers high strength-to-weight ratio and corrosion resistance but is more expensive than the other two materials.

Purpose and Use

Another factor that should be considered when choosing custom wheel adapters and spacers is the purpose. For racing or high-performance vehicles, lightweight adapters and spacers that minimize unsprung weight are essential. Off-road vehicles may require heavy-duty options to withstand rough terrain. Street use may not demand specialized features, but quality and durability should not be compromised.

Vehicle Requirements

It is important to take into consideration the vehicle specifications such as the make, model, and year. The specifications should be matched to the adapter and spacer options to ensure compatibility. This includes verifying bolt patterns, thread sizes, and clearance requirements. This would ensure safety and optimal performance.

Quality and Safety

Quality is paramount when choosing custom wheel adapters and spacers. Adapters and spacers should be sourced from reputable manufacturers that meet industry standards. Quality products undergo rigorous testing to ensure strength, durability, and precision. This would help prevent catastrophic failures, improve handling and stability, and enhance vehicle performance. The custom wheel adapters and spacers should have quality assurance certifications such as ISO or CE.

Thickness and Size

The custom wheel spacers thickness should not be overlooked as it plays a crucial role in the selection process. Depending on the desired wheel fitment and clearance issues, the size of the adapters should be determined. Choosing the wrong size could affect the vehicle's handling, stability, and safety.

Installation and Maintenance

Choosing adapters and spacers that are easy to install and maintain is recommended. Some adapters and spacers come with installation kits or instructions, making the process easier. It is advisable to choose products that require minimal maintenance, such as regular cleaning and inspection, to ensure optimal performance and longevity.

Replacing wheel spacers and adapters can be a simple DIY task that can be done at home. Below are some of the basic steps that can be followed:

Step 1: Gather all the necessary materials needed for the process. This includes a jack, jack stands, lug nut wrench, torque wrench, and basic hand tools.

Step 2: Park the car on a flat surface and loosen the lug nuts. After that, the car should be raised with a jack and secured on jack stands.

Step 3: Remove the wheels by removing the lug nuts and exposing the wheel hub.

Step 4: For wheel adapters, the initial step is to clean the surface of the wheel hub. After that, the wheel adapter is aligned with the bolt pattern and placed on the wheel hub. The bolts should be tightened evenly to secure the adapter. Then, the wheel is reinstalled and the lug nuts tightened.

For wheel spacers, the initial step is to clean the wheel spacer surface and the wheel's mounting surface. Then, the wheel spacer is aligned with the bolt pattern and installed onto the wheel hub. The bolts should be tightened evenly. After that, the wheel is reinstalled and the lug nuts tightened in a crisscross pattern.

Step 5: The manufacturer’s torque specifications should be followed when tightening the lug nuts using a torque wrench. This will ensure the even distribution of pressure and secure fitment. Once the process is completed, the car should be lowered and the jack stands removed.

Q1: What are the benefits of wheel spacers?

A1: Besides improving the vehicle's appearance by making it look meaner and aggressive, a wheel spacer has other benefits. A wheel spacer can increase a car's stability by widening its track. It can also improve the car's cornering ability. Installing a wheel spacer can fix a rubbing issue that is caused by suspension or chassis modification. In most cases, a wheel spacer can allow the fitment of a larger tire size.

Q2: How long do wheel spacers last?

A2: There is no specific time or mileage that can determine when a wheel spacer will start to wear out. However, buyers should be aware that a wheel spacer is a wearable part. Its condition can be affected by driving habits, the type of terrain, and the quality of the wheel spacer, among other factors.

Q3: Are custom wheel adapters and spacers safe?

A3: Yes, custom wheel adapters and spacers are safe. However, this is only the case if they are properly installed and maintained. Also, the custom wheel adapters and spacers must be the right size for a specific vehicle.

Q4: Do wheel spacers affect alignment?

A4: Installing a wheel spacer can affect the wheel alignment. This is because the wheel spacer alters the vehicle's track width. It can also put more stress on the suspension components. As a result, the camber and caster angles can be affected.

Q5: Can wheel spacers be fitted on any vehicle?

A5: Custom wheel spacers can be fitted on many vehicles, especially on trucks and 4x4s. However, it is important to check if a specific car is compatible with wheel spacers. Buyers can consult a professional mechanic.