All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(796 products available)

Magnifying sheets are of different types, and each has characteristics suitable for certain activities. They are obtainable in multiple strength focal points, sizes, and materials. Some of the more prevalent **custom PVC magnifying sheets** are listed below.

The magnification power of the Custom PVC magnifying sheets may be slight, about 1.5X magnification, or significant, reaching over 5X. In this case, such a property will depend on the lens used and the intended use.

Low Magnification

Low magnification is less than 3X, found in sheets that serve for broad examination or simple viewing. These are particularly appropriate for checking documents, photographs, or labels since they distort, and the images appear near the actual size.

High Magnification

High magnification, more than 3X, can better find fine details useful in specialized activities like scientific research or jewelry appraisal. However, it is essential to know that higher magnification means a smaller viewing window and possible distortion of the image.

**Magnifier sheets** are also produced with significant differences in thickness. Thicker sheets offer better magnification and higher image clarity. However, they become more composite and cumbersome when used. It is also necessary to use the appropriate thickness for the custom sheet by considering the main purpose intended.

1mm Thickness

These are relatively thin and are best suited for low-power magnification. They are lightweight and easy to handle when doing daily work or makeovers.

2mm Thickness

The 2mm sheets are a compromise between usability and power magnification. These are the best for complex applications such as model making and detailed artwork inspections.

5mm Thickness

5mm sheets are for specialized uses where that extra magnification counts. These sheets are probably heavy and not as easy to use if they are needed for lengthy processes.

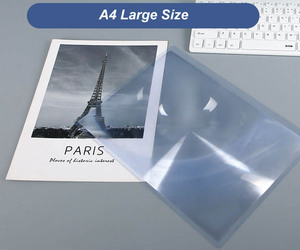

Magnifying sheets are obtainable with various dimensions so that the users can opt for a size that suits their needs and their profession.

Small-Sized

The small-sized magnifiers, say around 5x7 inches, are portable and convenient. They are largely applied in quick magnifications or as part of a kit for making miniatures.

Medium-Sized

Medium-sized sheets like 8x10 inches are the more frequently used size for general purposes. They are big enough to work with on a desk yet small enough to be portable.

Larger-Sized

Large sheets above 12x15 inches offer a larger viewing area, ideal for magnifying large objects or detailed blueprints. They are mostly fixed and designed for use on tables rather than for movement.

Certain features make **plastic magnifier sheets** desirable for given uses. They also improve the operation and explain the adaptability of such products. Some of these features include:

Some of the Custom PVC magnifying sheets carry an anti-fog coating, particularly in locations where humidity is a concern. These sheets stay clear for a long period of time and do not limit vision, so they are preferred for outdoor activities.

Heat-resistant PVC magnifying sheets are appropriate for periods when the sheets are to be used in hot settings. Unlike other types of plastic, PVC does not deform with temperature changes, making it a staple material in this magnifying glass.

Magnifying sheets stand out from other optical instruments due to their light weight. The sheets are portable and can be carried anywhere, making them appropriate for outdoor activities, inspections, and other fieldwork.

Magnifying sheets have another feature called a scratch-resistant surface. These additional coatings guarantee that the sheets will hold their magnifying potential for an elongated period while preventing damages from daily use.

The greatest advantage when it comes to these sheets is that they can be made to order regarding size and shapes. Custom magnifiers can serve their purpose in advertising, industrial inspections, or craft projects. They can be made in any shape or size to meet customers' needs.

Custom PVC magnifying sheets are employable in a number of business settings, and knowing this makes it easy to put such sheets in everyday use. Some of the current uses include the following:

Magnifying sheets are applied forwardly in the packaging and labeling industry to create friction and display certain product features. Such sheets are useful in enabling consumers to view fine details like ingredient descriptions or special features. Thus, it constructs a good experience and hence helps sales.

Security printing is affiliated with participate in preventing counterfeiting and enhancing guarantees on products such as currency, stamps, or event tickets. Custom magnifying sheets are integrated with security features like microtext or hidden images that are visible only after magnifying.

Such sheets are also used in quality assurance processes. In production lines, the plant managers use such a magnifier sheet to inspect defects, the alignment of components, and adherence to various labeling standards. This procedure helps eliminate inferior products in the market and, in the process, preserves brand reputation.

Custom PVC magnifying sheets are also common in the retail sector, as they are associated with custom magnifying glasses. This magnifying glass has a specific lens size and shape to magnify the items of interest. These come in handy for postcards, stamps, coins, or even jewelry.

The marketing approach in this context mostly uses custom PVC magnifying sheets. For instance, custom magnifying sheets can be inserted into direct mail campaigns to give the potential customers a special touch. These are also known as "tactile marketing," and it is a great way to improve brand memory and enhance the general experience of the customers.

Custom PVC magnifying sheets are common among artists and hobbyists. For example, in model building or scrapbooking, these sheets are normally used to view fine details or add optical effects to The artwork. These sheets are cut into custom sizes and shapes to fit specific projects, providing the crafters with the flexibility to design.

When selecting Custom PVC magnifying sheets, several key factors must be considered. These factors affect the effectiveness, usefulness, and longevity of such products.

Knowing the primary purpose of a Custom PVC magnifying sheet is the key to its selection. A more normal magnification such as for document verification does not require much magnification power or thickness. Conversely, more such sheets are needed in activities such as scientific research to ensure that the magnifier sheets are **scratched plastic magnifying sheets** to avoid ambiguity when viewing fine details.

Some PVC magnifying sheets have a UV protection layer. If such sheets will be subject to sunlight for a long time, as is the case with outdoor stationery, selecting a UV-protected sheet is worth it. These sheets don't just protect the magnifier sheets from yellowing; they also increase their usefulness by protecting them from harmful rays of sun.

Optical clarity is among the most important magnification sheet features. When choosing a sheet for use, ensure the sheet has good optical clarity and no distortion. This is particularly important to objects needing sharp and clear images, such as maps or technical drawings.

Durability and the type of material play an important role in this process. Stainless steel sheet magnifiers are ideal for tasks such as inspections and outdoor activities. Thus, it contributes to longevity, as they can deal with such rough handling.

Custom PVC magnifying sheets offer various shapes and dimensions in the craft and business world. So, if the magnifying sheet is intended for a special purpose, ensure that it is available in that size and form. In other words, such a product can be cut and shaped to fit specific needs.

Magnifying sheets vary in thickness; the thicker the sheet, the stronger the magnification and the higher the image clarity. However, this also means that the magnifying sheet is heavier and not very easy to work with. When choosing a Custom PVC magnifying sheet, ensure that the thickness is balanced with the magnification.

A1: A magnifying sheet should be 2 mm thick for professional use. This thickness provides a good balance between clarity and ease of handling.

A2: Yes, and custom PVC magnifying sheets are ideal for outdoor use. They are waterproof, durable, and resistant to UV rays and fogging, making them perfect for outdoor inspections or activities.

A3: Yes, custom PVC magnifying sheets can be cut into specific shapes. They can be easily cut with scissors or a craft knife to create custom sizes and shapes.

A4: Custom PVC magnifying sheets can offer a maximum magnification power of up to 5X. This makes them suitable for detailed inspections in various professional fields.

A5: These sheets are more versatile than traditional magnifying glasses. They can be customized in size, shape, and thickness to fit specific needs, whereas magnifying glasses are usually fixed in size.