(1016 products available)

The csi flat panel detector comes in diverse types, each constructed for particular medical imaging requirements. These types are detailed below:

Direct Flat Panel Detectors

The direct flat panel detectors convert X-ray photons straight into digital images through a technique called direct conversion. In this approach, a layer of cadmium selenide (CdSe) or scintillation is utilized to capture incoming radiation. Consequently, this leads to high-quality image acquisition with stellar resolution and contrast familiar in systems like CT and MRI scans. Direct detectors are widely used in intensive medical settings due to their precision and reliability.

Indirect Flat Panel Detectors

Indirect flat panel detectors function by converting X-rays into visible light before the conversion to digital images. Usually, these devices integrate a scintillation layer fashioned from cesium iodide (CsI), which produces photons of light upon X-ray exposure. Following this, an array of amorphous silicon (a-Si) captures the resultant light and converts it to an image. These detectors are favored in radiology for their exceptional image quality and high resolution.

Wireless Flat Panel Detectors

These feature the convenience of wireless data transmission. Usually, they are specially designed for flexibility and ease of use. Often, wireless flat panel detectors feature built-in Wi-Fi or Bluetooth functionality. This allows seamless transfer of images to medical systems or archives without the hindrance of cables. Their compactness makes them ideal for portable devices in emergency medicine or field hospitals. Nevertheless, they may be heavy compared to wired alternatives.

Clinical and Surgical Flat Panel Detectors

Cesium iodide (CsI) and amorphous selenium (a-Se)) are usually the most applicable flat panel detectors in surgical and clinical environments. These settings necessitate real time, high-resolution imaging for procedures like angiography and fluoroscopy. Commonly, these detectors are built to endure the intense demands of frequent usage. Normally, they are designed to be compact and easily integrated into existing medical systems.

Aerospace Inspections

The flat panel xray imager plays an essential role in the identification of structural defects in such areas as aircraft components and fuselage welds. Conventionally, it has the ability to deliver high-resolution images which enable the detection of minute cracks, voids, and other defects that can negatively affect aircraft performance. Usually, its application promotes safety and reliability in fleet maintenance as well as in the advancement of regulatory compliance in the aerospace industry.

Automotive Testing

Commonly, flat panel detectors are used in non-destructive testing (NDT) in the quest to inspect welds, joints, and composite materials in vehicles. Normally, high-quality images help in identifying weaknesses early in the production process. This ultimately results in reducing the risk of component failure. In addition, they ensure adherence to safety standards and functionality.

Manufacturing Quality Control

In the manufacturing industry, flat panel detectors are crucial when it comes to inspecting a broad spectrum of products. This encompasses welded metals, industrial machinery, and electronic components. Typically, their capacity to capture minute details enables the identification of defects such as misalignments, solder issues, or internal cracks. Conventionally, this proactive identification of defects has the ability to reduce rework costs, enhance product quality, and ensure safety. This detectors are critical for effective production workflows.

Construction and Civil Engineering

In construction, flat panel detectors examine welds and joints in structures like bridges and skyscrapers. Therefore, by providing clear images of internal defects, they enable engineers to ensure structural integrity. Moreover, this capability reduces the risk of catastrophic failure. Often, it results in long-term savings by mitigating the need for costly repairs down the line.

Energy Sector Inspection

In the energy sector, flat panel detectors are applied in the examination of pipelines, pressure vessels, and welds in refineries and power plants. Usually, their ability to detect internal flaws aids in preventing leaks or failures. This enhances operational safety. Besides, it reduces downtime by ensuring needed maintenance and repairs are done proactively.

Portability and Size

Flat panel detectors are designed in a compact manner which makes them easy to carry and maneuver in diverse settings. While in most cases, their dimensions approximate the size of a standard digital tablet, they weigh significantly less. Consequently, their portability makes them ideal for both hospital rooms and in the field.

Real-Time Imaging

The csi flat panel detectors offer real-time imaging that is essential for dynamic procedures. Often, physicians receive instant feedback that enables prompt decision-making during surgeries or interventional procedures. This capability results in improved patient outcomes and enhances efficiency in medical settings.

Durable CsI Scintillator

Usually, cesium iodide (CsI) is used in the flat panel detectors as the scintillator. Commonly, it has a high packing density that guarantees optimal X-ray conversion to visible light. In addition, CsI's needle-like crystal structure minimizes light dispersion. Therefore, it leads to sharp images with superior contrast and resolution.

Wide Dynamic Range

Normally, the dynamic range is expansive, enabling the detection of both low and high X-ray dose areas in a single image. Therefore, this versatility makes them fit for various applications. These applications range from routine radiography to complex fluoroscopic procedures. Moreover, a wide dynamic range minimizes the need for retakes. This enhances workflow efficiency.

The Cylindrical flat panel detector holder is installed in a couple of simple steps. They include:

Mounting the Detector on the X-Ray Machine

Users should position the flat panel detector into the bucky tray or fixed mount on the X-ray machine by aligning it with the central X-ray column.

Connecting the Cables

Users should refer to the machine's manual for the precise cable connection. In instances where the detector is wireless, the user should ensure the wireless settings are correctly configured.

Powering Up the System

They should power up the X-ray machine and the connected computer or digital display to access the imaging software.

Software Configuration

The users should launch the imaging software and configure it in line with the machine's specifications and the detector's settings.

Calibration

After configuration, they should conduct calibration. This enables the detector and machine to create precise images. Users should follow the calibration procedure as stipulated in the software.

Testing

Finally, after completion of the above steps, users should run a test by conducting a dummy X-ray to check the system's working efficiency. They should make image adjustments if necessary.

Proper maintenance of the csi flat panel detector enhances its longevity and efficacy. Here are some ways of maintaining it:

Routine Cleaning

Users should clean the detector regularly using a soft, lint-free cloth to remove contaminants like dust and fingerprints. They should avoid abrasive materials that may scratch the surface. Also, they should ensure they use only approved, gentle cleaning solutions that are suitable for electronic devices. Note, excessive moisture on the panel can result in damage.

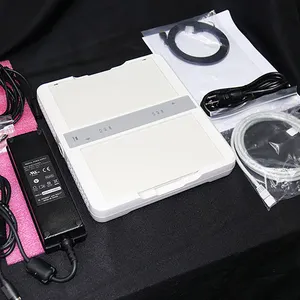

Proper Storage Conditions

When not in use, the detector should be stored in a dry, temperate environment free from direct sunlight. Also, users should keep it in the protective case that comes with it to avoid unplanned physical damage. They should avoid extreme humidity that can corrode internal components.

Regular Software Updates

The detector's performance may be impacted in the absence of software updates. Therefore, users should consistently check for and install updates from the manufacturer's website. This guarantees enhanced effectiveness, security, and improved feature accessibility.

Damage Monitoring

The user should inspect the detector occasionally for any signs of damage or wear. These include cracks or loose connections. Further, they should report any detected issues immediately to the manufacturer for appropriate repair or replacement guidance. Proactive damage monitoring minimizes further degradation and maintains the gadget's functionality.

Avoiding Excessive Pressure

While transporting or using the detector, users should avoid applying excessive force or pressure on its surface. This is due to the fact such activities can lead to internal damage or malfunction. in addition, they should avoid placing heavy items on top of the panel to protect its integrity.

JBiperatthe following factors helps wholesalers and business owners stock the right flat panel detector.

Type

Buyers should consider the kind of panel detector that suits their clientele's needs. They include direct and indirect digital radiography systems. Each type has its own merits. For example, direct detectors offer better image quality. On the contrary, indirect detectors are more cost-effective.

Supplier reputation

Business owners should prioritize stocking detector systems from reputable manufacturers. Such organizations use quality materials to manufacture their products. Also, they offer warranties for their systems. In addition, they have customer service departments that respond promptly to customers' issues.

Specifications

Business owners should consider various technical specifications. They directly impact the device performance and image quality. Some of them include the pixel size, dynamic range, and detector material. Each specification has a different impact depending on the medical condition being treated.

Image quality

Wholesalers should get flat panel detectors that offer quality images. Usually, they determine the quality of the images the detector can produce. Buyers should also consider the size of the panel. Bigger panels allow greater imaging areas.

Compatibility

Buyers should ensure the flat panel detectors they purchase are compatible with existing radiography equipment. They should also prioritize those systems that are easy to integrate with other digital medical gadgets.

Pricing

Retail store owners should buy flash panel detectors at various price ranges. They should also consider the total cost of ownership. Cost-effective systems have low maintenance costs. At the same time, they consume less power. Business owners should also consider the financing options available.

Market trends

Buyers should research the current trends in the flat panel detector market. Usually, they affect the demand and supply of these systems. For instance, there is an increase in demand for wireless flat panel detectors, as they are easy to use. This is because they allow users to wirelessly transfer images. On the other hand, conventional ones require the users to connect them using wires.

Here are some FAQs flat panel detector wholesalers and business owners should expect from their customers:

What is a csi flat panel detector?

It is a medical imaging gadget used to create radiographic images. Usually, it converts X-rays into high-quality digital images. It is made using cesium iodide and amorphous silicon.

Which are the primary features of csi flat panel detectors?

Its key features include a high-resolution scintillation crystal (cesium iodide), a wireless design option, compatibility with multiple imaging systems, and the ability to operate in real time.

Which are the industrial applications of the csi flat panel detector?

They are used for quality control in manufacturing. Also, they inspect constructed buildings and repair pressure vessels and pipelines. Lastly, they are used in the aerospace sector for inspecting fuselage welds and aircraft components.

How should the csi flat panel detector be maintained?

For longevity, users should clean the flat panel detector regularly using a soft cloth. They should store it in a dry environment and avoid exerting excessive pressure. Additionally, they should check for software updates and report any issues to the manufacturer.

Which factors should be considered when purchasing flat panel detectors

Wholesalers should consider the type, specification, and image quality of the flat panel detector. Also, they should check its compatibility with other imaging equipment.