(5896 products available)

Market Overview: The global market for conventional lathe machines is positioned for steady growth, with the overall lathe machines market estimated at US$12.4 billion in 2023 and projected to reach US$15.4 billion by 2030, growing at a CAGR of 3.2% during this period, according to Global Industry Analysts. This growth is significantly influenced by the automotive sector, expected to reach US$7.3 billion by 2030, with a CAGR of 3.8%, highlighting the increasing demand for precision-engineered components. The U.S. market alone was valued at approximately $3.3 billion in 2023, while China is poised for robust growth at a CAGR of 4.7%, reaching $3.0 billion by 2030, indicating a shift in manufacturing capabilities towards regions with enhanced industrialization.

Consumer Behavior and Trends: The demand for conventional lathe machines is being driven by the expansion of the manufacturing sector and the rising adoption of automation technologies. As industries increasingly focus on precision manufacturing, the need for reliable and efficient machining tools has surged. Additionally, the integration of IoT and Industry 4.0 principles into manufacturing processes is reshaping consumer expectations, with buyers seeking machines that offer high precision and reduced operational costs. However, manufacturers face challenges such as the high costs associated with advanced lathe models and a shortage of skilled labor, which could impede market growth. Nonetheless, opportunities remain for innovation in machine design and technology, especially in emerging markets like China and India, where investments in manufacturing infrastructures are on the rise.

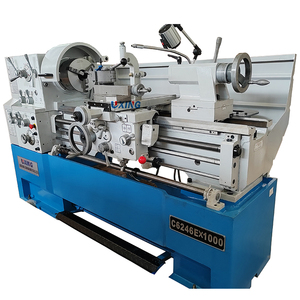

A conventional lathe machine is widely used for different machining processes, such as cutting, drilling, sanding, knurling, boring, and facing. There are various types of lathe machines based on their design, function, and application.

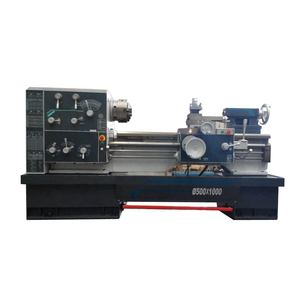

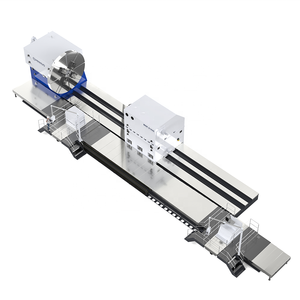

Conventional metal lathe machines have various specifications, including the swing over bed, maximum machining length, spindle speed, spindle taper, motor power, dimension and weight.

Periodical maintenance of the lathe machine tool is a critical task. With periodical maintenance, the machine's precision will be maintained, and the lifespan will be increased to cut down on the cost of repairs and replacements.

Begin the lathe machine maintenance routine by cleaning the tool. Every day, the operator should remove any bulk or round chips and dust on the bed, around the tool post, on the cross rail, and on the carriage. They should clean all the surfaces and around the controls.

Use a soft brush, a feather duster, or an air gun to remove the residual chips around and underneath the lathe. On the threaded parts of the saddle and the cross rails, use a rag to remove any residual chips. On the racked part threaded, put some oil on the coarse thread to lubricate it. Prior to putting off the lathe machine tool, the operator could put a thin layer of grease on the slide surfaces for lubrication and to prevent rusting as long as it is clean.

When cleaning the machine tool, make sure no electrical parts or painted parts get wet. Other parts can be cleaned with a dry cloth.

When removing any chips from the lathe tool, make sure no chips fall into any rotating spindle holes.

Besides regular cleaning, operators should regularly oil the lathe machine tool per the manufacturer's instructions. The oiling points include guides, dovetail, gibs, and slides, among others. Use the right type of oil on the lubrication points as outlined in the manual.

The following sectors use conventional lathes for various applications.

Machine shops

Machine shops use conventional lathes to make and repair parts from different materials. The repairs include worn or damaged threads, sleeves, and bearings. The machine makes custom and replacements components for several assemblies and sub-assemblies.

Construction

Construction uses the lathe machine to make parts for scaffolding, window frames, gates, and fences. The machine customizes wood and plastic pipe to fit the construction plans. With the lathe and proper attachments, workmen can join, groove, and thread pipes. The machine makes the job easy and faster than manual methods.

Aerospace

The aerospace sector makes precision parts for ships and airplanes. It uses CNC lathes because they cut with higher precision. This type of lathe also produces complex aerospace components with little human intervention.

Automotive industry

Automotive uses the lathe machine to produce interior and exterior automobile parts. Some are made from wood, but plastic and metal are more common. The automotive industry uses CNC (Computer Numerical Control) lathes. With Computer Aided Design (CAD) software, designers can create parts with complex shapes that fit exactly. The CNC machine makes them in large volumes with high precision and low tolerance. Some CNC machines combine lasering and lathing for even better results.

Electronics

The electronics industry uses the machine to make housings for electronic meters, gauges, and dials. The conventional lathe makes the housings from plastic or aluminum. It also makes knobs, shafts, and other related accessories.

Maritime

The maritime sector makes or repairs parts for ships and boats. Common jobs include making marine engine parts, propeller shafts, thruster shafts, and other components. Some are fitted with rubber or Teflon seals. The seal fit requires high precision, so the job is done with a CNC lathe.

Furniture industry

The furniture industry uses the lathe to customize solid wood, MDF, and plastic parts. With the machine, the operator creates elegant designs like spiral legs, arches, coves, and other decorative elements.

When buying a conventional lathe, it's crucial to consider the size, build quality, control system, spindle speed and power, available attachments and accessories, as well as safety features.

Machine size to work on metal parts:

Check the maximum length and diameter of the metal workpieces the lathe machine can handle in terms of its bed length and swing. If there is no limitation to the size of the workpieces that can be processed, it may result in a huge expense.

Durable metal construction:

A sturdy and durable metal frame is essential for supporting the machine itself and ensuring the precision machining of workpieces. To enhance stability and reduce vibrations during operation, the base of the lathe should have sufficient weight and a large contact area with the ground.

Manual or digital operation:

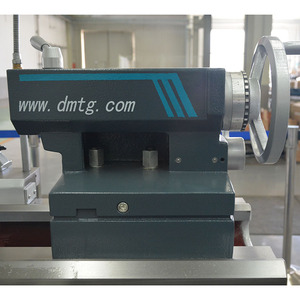

Determine whether the machine is controlled manually or electronically, and select an easy-to-use model according to one's skills and experience. The electronic control system enables more precise machining, simpler operation, and faster lathe setup.

Speed and power:

The spindle speed of a conventional lathe usually ranges from hundreds to thousands of revolutions per minute. Select a machine with sufficient spindle power and speed for the needed processing accuracy and efficiency.

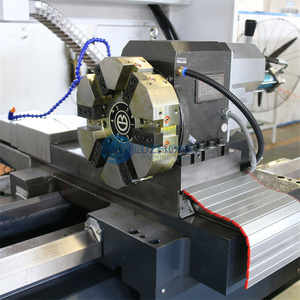

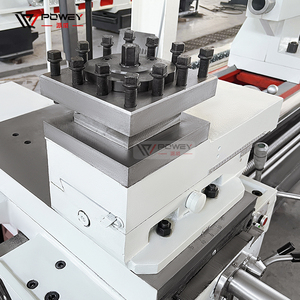

Other useful accessories:

These may include a drill chuck, three-jaw or four-jaw chuck, tool post, collet, thread-cutting attachment, faceplate, steady rest, follower rest, cross-slide, etc. Some accessories can also be conveniently added to the lathe later on, so be sure to check their compatibility.

Safety features:

These include emergency stop buttons, protective enclosures, resistance to overloads, and overheating protection.

Q1: What is the difference between a conventional lathe machine and an CNC lathe machine?

A1: The working principle of a CNC lathe machine is similar to that of a conventional lathe machine, but the CNC machine is computer controlled or automated, while the conventional machine requires manual control. CNC lathes are usually more precise than their conventional counterparts. Also, a CNC lathe machine has a tool turrett that is programmed to move with the workpiece, while a conventional machine has single point tools that must be manually swapped out and repositioned.

Q2: What is the largest size of a conventional lathe machine?

A2: Lathe machines come in many sizes. Larger machines are typically used in industrial settings and have a swing over bed of up to 2,000 mm and a distance between centers of up to 6,000 mm.

Q3: Is a conventional lathe machine good for beginners?

A3: Yes. Due to their simple design, many people use a conventional lathe machine for metal work before moving on to more advanced machines like the CNC lathe. However, even with their simple design, a conventional lathe machine requires the operator to have some knowledge and skill to be able to use it properly.