All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1754 products available)

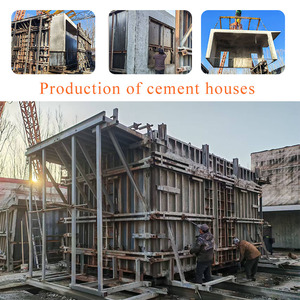

Concrete swimming pool formwork is a mold system used to hold wet concrete in place until it cures into a desired structure. It's essential in constructing concrete pools. Once the concrete sets, the formwork is removed, leaving a solid concrete structure.

Concrete formwork comes in different types based on materials, reuse, and applications. Based on materials, the types include;

Material and Design:

A concrete pool formwork is primarily made up of steel, plastic, or wood. Their design is always modular, promoting reusability and customization. Their construction consists of robust materials, ensuring they withstand pressure during the pouring process. There are different types of concrete pool formworks, each tailored for specific project needs.

Durability and Strength:

This feature ensures an efficient and effective concrete pouring process. It minimizes the need for repairs and replacements, promoting long-term use. Their durability and strength offer precise and smooth finishes, creating a stable and robust structure.

Ease of Assembly and Disassembly:

This feature enables quick assembly and disassembly, enhancing labor efficiency and reducing time. It minimizes project time and cost, promoting formwork flexibility and adaptation to various pool designs and sizes.

Cost-Effectiveness:

The formwork for concrete pools is constructed with durable materials, ensuring longevity and minimizing maintenance costs. Its modular design promotes reusability, allowing pool contractors to use the same formwork for different projects, thus reducing overall project costs. Additionally, the ease of assembly and disassembly minimizes labor costs, making concrete pool formwork a cost-effective solution for concrete pools.

Versatility:

This allows the formwork to cater to different pool shapes and sizes. It's suitable for in-ground and above-ground pools, enhancing its applicability in various construction projects. Additionally, concrete formwork provides adaptability, enabling the customization of formwork to meet specific project requirements. This feature also allows the adjustment of formwork to accommodate various pool designs, enhancing efficiency and effectiveness.

Sustainable Practices:

This promotes the reusability and recyclability of materials used in designing concrete pool formwork. It minimizes waste during the construction process and encourages the efficient use of resources. Sustainable practices ensure the formwork is constructed with eco-friendly materials, contributing to environmental conservation.

The formwork for concrete pools is applicable in various scenarios. Here are some of them:

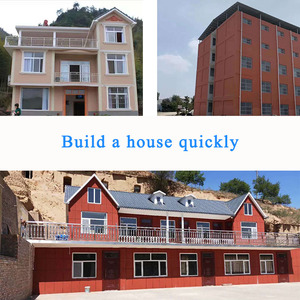

Construction Projects

Concrete pool formworks are used in construction projects of all sizes. This includes residential houses, high-rise buildings, commercial centers and bridges. The formwork provides a mold for concrete to set into desired shapes and structures.

Concrete Pools Installation

Concrete formworks are essential for building concrete swimming pools. They are installed and filled with concrete, creating a pool that can last for years.

Retaining Walls

Formworks are used to construct retaining walls. The formworks create a wall that can hold soil back during landscaping or other activities done in a property site.

Basements

Concrete formwork is used to create basements in building structures. The formworks provide an enclosure for the concrete to create a solid basement structure.

Column and Beams Construction

Colums and beams are crucial in providing support and stability to structures. Pool formworks are used to construct colums and beams in buildings. This is due to their ease of use and ability to create structures of different shapes and sizes.

Architectural Features

Concrete formworks are also used to construct architectural features such as awnings, archways and overhangs. The formworks are customized to create the desired shape of the structural features.

Infrastructure Projects

Concrete formworks are used in different infrastructure projects, including building bridges, tunnels and highways. The formworks help create strong and durable structures that can withstand different loads and stresses.

Heavy Commercial Construction

Formworks for concrete pools are used in commercial construction sites, such as power plants, factories and warehouses. The formworks help construct large-scale structures with precision and strength.

High-Rise Construction

Concrete formworks are used in high-rise building construction. This includes hotels, residential apartments and office buildings. The concrete forms can be repetitively used for multiple floors, making them a cost-effective option for formworks.

When choosing the concrete swimming pool formwork, there are some factors one should consider. This includes:

Size and shape of the pool

The size and shape of the pool determine the type of formwork to use. A large or complex pool requires a more advanced formwork system. In contrast, a small pool can use simple formwork.

Type of concrete pool formwork

There are different types of concrete pool formworks, each with unique characteristics. For instance, reusable PVC formwork is lightweight, durable, and provides a smooth finish. Steel formwork is strong and perfect for large pools. Wood formwork is cost-effective for small pools. It is essential to choose a formwork type suitable for the project concrete pools' size, shape, and budget.

Construction materials

The construction materials of the formwork influence its performance and output. For example, steel formwork offers superior structural integrity and durability. PVC formwork is convenient and provides a consistent finish. Wood formwork allows flexibility in terms of shape and size. It is important to choose a construction material that meets the requirements and pools budget.

Quality and condition of the formwork

When choosing concrete formwork, either new or used, inspect its quality and condition. If using new formwork, ensure it is of high quality and built to withstand the pool's concrete pressure. If using used formwork, ensure it is in good condition and capable of producing the required output.

Budget

Budget is an important factor when choosing formwork for concrete swimming pools. Different types of formwork have different costs. For instance, steel formwork is more expensive than wood formwork. It is essential to choose formwork that one can afford without compromising the quality and structural integrity of the swimming pool.

Q1: Are there any special maintenance requirements for concrete pools?

A1: Not really. Concrete pools need regular cleaning and chemical balance maintenance identical to formwork pools. However, concrete pools require more regular vacuuming because of the rougher surface that can harbor debris. They also require frequent brushing to maintain smooth, stable water levels.

Q2: How long does the construction of a concrete pool take?

A2: A concrete pool can take about 3-4 weeks to complete. However, this depends on various factors, such as the weather and the pool size and type. For instance, a shotcrete pool may take less time to construct than a gunite pool.

Q3: Can the concrete formwork be reused?

A3: Yes, the concrete formwork can be reused several times. However, this will depend on the type of formwork. For instance, steel formwork can be reused up to 100 times, while plywood formwork can be reused 15-25 times.

Q4: What is the most challenging part of building a concrete pool?

A4: The most challenging part is ensuring the water stays level during the curing process. This is especially the case with gunite pools where formwork has to be used to create walls and floors. Proper curing also takes time, and weather conditions can affect the process.