All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2658 products available)

A concrete conveyor system is extremely useful on a construction site where large volumes of concrete is either required or produced. These are used due to the labour and time saving benefits they provide. They can be categorized into several types based on functionality and how they are constructed. Below are some common types of concrete conveyor systems.

This type of concrete conveyor is mainly used in excavation sites. They are a very mobile system with good off-road capability and so ideal for uneven or difficult terrain. As caterpillar tracks enable the unit to traverse all manner of site topography with ease. Even pointed or sloped ground. They provide a firm base on which liquid concrete pumps can be placed safely, eliminating the need for many manual concrete placing methods. This not only speeds up the whole process but also makes the pumping system less vitiated.

This is a types of fixed conveyor that employs a series of flights or plates attached to the carrying chain. It is commonly used in industries for handling bulk materials like aggregates, ores, grains, etc. The flights are raised at an angle to the horizontal, which causes the materials to be transported to the desired height or distance. The movement of the chain drives the flights, enabling a continuous flow of material with minimal spillage.

The concrete version of a flight conveyor would be similar, having flights or blades fixed on a horizontal rubber belt that would transport concrete in a designated closed trough.

Its construction ensures that even in its small, medium, or high-speed variety, which is much faster than other screw types, there are nominally few damage incidences. However, they cannot handle very large lumps because this may require equipment of extra size and lead to excessive wear and tear. Also, it is less flexible when compared to bucket and screw conveyors.

The belt conveyor is included in almost all types of industries for all bulk material needs because of the advantages it has. For instance, belt conveyors can handle a varying range of material sizes, including large and small concrete aggregate. They can operate on flat as well as inclined surfaces and be used indoors or outdoors. There is no industry exclusion due to the flexibility and versatility of its application. They epitomise low maintenance as they are effectively only a single belt running on pulleys without many moving parts to wear out. However, Chan, Belt conveyors are unsuitable on construction sites because of their limited capacity and effectiveness about large, coarse aggregates.

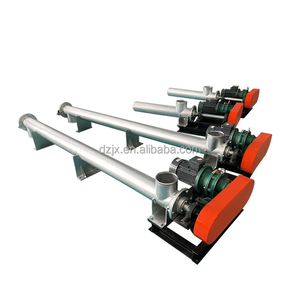

A screw conveyor comprises a helical screw blade on a shaft within a tubular casing, used to move granular or powdery materials. It is also known as a spiral or auger conveyor.

The screw rotates around the shaft, transporting the material along the length of the conveyor. The pitch of the screw determines the speed and amount of conveyed material. A tighter pitch slows the flow, allowing the movement of thicker materials, while a looser pitch increases the flow rate.

Screw conveyors are commonly used in various industries such as agriculture and construction. The advantages of a screw conveyor include:

Concrete conveyor systems have many applications beyond the construction industry. Even in the construction industry itself, they have many applications to different kinds of construction material and concrete needs.

In mining and mineral processing industries, conveyors move extracted minerals, ores, and materials for crushing or processing. Some common areas of use include conveyor systems used in:

In mining and mineral processing industries, conveyors move extracted minerals, ores, and materials for crushing or processing. Some common areas of use include conveyor systems used in:

The above examples only illustrate how concret conveyor systems can have diverse and widespread applications – making them indispensable across various industries.

Concrete conveyor systems comprise several key features that enhance their functionality:

Prior to installing a concrete conveyor system, it is imperative to perform an installation site analysis that studies the areas of operation and movement of the system and the accessibility of the concrete source. This will appropriately inform the placement of the system.

The following steps are a guide to installing a concrete conveyor system:

Like any mechanical system, concrete conveyor systems require regular maintenance and repair. Here are some key points:

The main factored items when buying/transacting a concrete conveyor system involve what the buyer requires and, at the same time, putting attention to the quality of the product and the reputation of the manufacturer. Below are several important factors to consider:

Volume capacity or throughput is the principal factor. Systems that have higher throughput means they will convey larger quantities of concrete per hour. Hydraulic pump operators and conveyor belts have high volume capacity than their-kind counterparts, while screw and flight conveyors have low volume capacity than them.

Distance also matters since concrete conveyor systems are devised to convey concrete for specific distances. Some systems can convey concrete for barely 10 meters, while others can convey concrete for up to a distance of 200 meters. Hence, when selecting a system, make sure to check that it can effectively convey concrete to either the nearest place or the farthest place on the construction site. Belt conveyor systems are good at long-distance conveyance, while spider and buggy concrete conveyors are good at short-distance conveyance.

Budget constraints will also have some impact on the choice of system, albeit to a lesser extent. It would therefore be pertinent to get quotations from several reputed manufacturers and suppliers, perhaps even bargaining hard, and investing the amount in purchasing a good, proactive and warranty-protected product. Even in the industrial sector, this is the case. Generally, belt conveyors, which are inexpensive to buy, can be expensive to run and maintain, whereas hydraulic cranes that are expensive to buy initially can be inexpensive to run and maintain and give out high performance compared to cheap systems.

Last but not the least is that the easiness of operation of the concrete conveyor system is essential in making a drug-free and easy-operating choice. Simple controls with smooth operating practices will generally make the system more user friendly to operate, especially on tough and challenging work sites. It is recommended to have the operator trained and skilled to handle the system properly and safely. Some of the hard and difficult manoeuvres that require greater levels of skill in handling may be subjected to more sophisticated systems like hydraulic conveyors or spider conveyors, and such smooth running systems can also be made relevant for longer periods of operation without fatigue. Hence, the time and cost involved in operation will be influenced by the level of sophistication and the quality of the operational ease.

A1: A concrete conveyor system is a mechanical system that is used to convey the concrete from one place to other on a construction site. Concrete conveyor belts work by continuously moving a flexible rubber belt over pulleys to deliver concrete from a hopper to the construction location.

A2: The advantages of concrete chutes are that they cost less, are time saving, minimize wastage of resources, and can be used even in restricted access areas on a construction site where normal vehicles cannot operate. They also eliminate or reduce the need for manual mixing and pouring of concrete to minimize work-related injuries.

A3: Conveyor systems can be powered or manual, horizontal or vertical, and portable or fixed, depending on the circumstances of their possible use. The common types that can be deployed on construction sites include drum, belt, screw, hydraulic, and pneumatic concrete mixers and conveyors.

A4: The concrete conveyor system is selected based on project-specific variables such as distance and height to which the concrete is to be delivered, site conditions, volume of concrete required, and budget constraints. In difficult access areas, pneumatic and hydraulic concrete conveyor systems are the best, while belt and screw conveyor systems are best where high volume is required.

A5: Daily maintenance includes lubrication, wear and tear check, and cleanliness maintenance. If there are mechanical problems like wear and tear of the belt, scree, or parts, they should be repaired immediately, or a new part should be replaced.