(1322 products available)

A cnc tool storage rack is a device used to store and organize CNC tools on a CNC machine. There are different types of CNC tool storage racks designed to meet different needs. Some are built into CNC machines, while others are standalone units made for workshops.

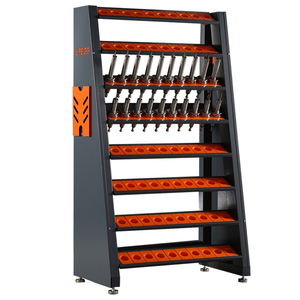

Vertical storage racks

Vertical storage racks utilize the vertical space of a workshop or storage area, making them ideal for places with limited floor space. With these racks, CNC tools are stored in a vertical position. Vertical storage racks are suitable for storing long tools such as end mills, drills, and reamers, as they can hold these tools in a vertical orientation. Vertical storage racks are usually adjustable so that CNC tools of different sizes can fit well.

Horizontal storage racks

Horizontal storage racks are suitable for storing various CNC tools. They organize and store CNC tools horizontally, which is great for keeping heavier or longer tools steady and safe. Horizontal storage racks are generally more accessible than vertical ones, making them suitable for workshops where operators need to access tools quickly.

Wall-mounted storage racks

Wall-mounted storage racks are designed for workshops or rooms with limited floor space. These racks are mounted on the wall and can hold a variety of CNC tools. Wall-mounted storage racks make it easy to access and store tools, which helps keep the workspace tidy and improves operational efficiency.

Tool cabinets

Tool cabinets are enclosed storage furniture that provides secure storage for CNC tools. They usually have several drawers or compartments of different sizes to organize and store tools. Tool cabinets can be designed to accommodate various CNC tools, keeping them safe from dirt and damage.

Tool chests

Similar to tool cabinets, tool chests provide a mobile storage solution. With rolling casters, tool chests can be moved around the workshop, allowing easy access to CNC tools wherever needed. Tool chests typically have more drawers and compartments, providing flexible and practical storage options for CNC tools.

Magnetic tool holders

Magnetic tool holders use magnets to keep CNC tools in place. These holders can be attached to wall-mounted racks, cabinets, or tool chests, saving space and making it easy to access CNC tools. Magnetic tool holders are suitable for smaller tools like drills, end mills, and inserts, keeping them organized and within reach.

Rotary tool racks

Rotary tool racks allow for easy access and storage for CNC tools. These racks typically have multiple layers or tiers that can rotate, making it easy to view and获取工具。旋转式工具架尤其适合存放种类繁多的小型cnc工具,保持有序且易于取用。

Drawer式工具架

这些工具架配有多个抽屉,便于将cnc工具分类存放。每个抽屉可以贴上标签,标明所存工具的种类,方便查找。抽屉式工具架能够有效防止工具交叉磨损,延长工具使用寿命。

Perforated tool boards

这些工具架由穿孔的工具板组成,能够灵活地将cnc工具悬挂在板上。用户可以根据需要自由调整工具的高度和位置,便于快速取用和归位。穿孔式工具架适合需要频繁更换和调整工具的工作场景,确保工作效率。

Designing a CNC tool storage system requires a meticulous approach to ensure that it meets the needs of the machine and the workshop environment. The first step in this process is to assess the specific requirements of the CNC machine, including the types of tools used and their sizes. This assessment will help determine the capacity and dimensions of the storage system.

Next, choosing a suitable material for the storage system is crucial. Commonly used materials include steel, aluminum, or high-density plastics, all of which offer durability and resistance to wear and tear. The storage system can be designed as a freestanding unit, wall-mounted, or integrated into the CNC machine itself, depending on space availability and budget constraints.

One of the critical aspects of designing a CNC tool storage system is ensuring easy accessibility and organization of the tools. This can be achieved by incorporating features such as labeled drawers or bins, tool holders, and racks. Additionally, implementing a tool inventory management system can help keep track of the tools and their usage.

Moreover, designing the storage system to accommodate future expansions or modifications is essential, as the workshop's needs may change over time. Reinforcing the storage system's structural integrity and stability is equally important to withstand the heavy loads and vibrations associated with CNC machining.

Lastly, ensuring that the storage system complies with the relevant safety and industry standards is paramount to guarantee the safety of the workshop personnel and the tools. In conclusion, designing a CNC tool storage system necessitates a comprehensive understanding of the workshop's needs and the CNC machining process, coupled with a focus on durability, accessibility, and safety.

Production facilities

In a large factory producing goods at scale, many CNC machines may be used in different areas for parts-making. A CNC tool storage cabinet can be placed in each area so that all tools needed are kept in one place for quick retrieval. This prevents delays that may occur if a needed tool is found somewhere else or missing.

Educational institutions

Colleges and universities with programs on CNC technology and machine tool operation need to train students on how to work safely around machines. Part of this training involves showing them where to find cutting bits and other supplies necessary for running these equipments. Using racks to organize this information makes it easy for instructors to supervise students as they learn. It also helps them emphasize the importance of tool management in workshop safety procedures.

Research labs

When developing new processes or testing new ideas related to CNC machining, researchers need to access their working instruments. If a lab has a lot of different types of end mills and drill heads, it may use specialized racks that clearly label compartments according to the specific tools contained therein. This way, when a researcher writes down which tool was used during an experiment, it will be clear what is meant simply by referring to the storage system.

Woodworking shops

Woodworkers who use computer-controlled routers and laser cutters can also benefit from having dedicated spaces for keeping their cutting tools. Since these kinds of tools are usually sharp and should be handled carefully, keeping them neatly arranged on a CNC tool storage rack reduces the risk of accidents occurring due to mishandling. It also helps the craftsmen quickly identify the required bits when switching between different projects involving woodwork.

Mold-making facilities

In shops where molds for casting metals or plastics are made using CNC machines, racks storing toolsets such as ball end mills must be close by. Organizing such a rack according to the size of each tool allows the machinist to select the most appropriate one. This ensures that there is no unnecessary delay in switching tools while working on different parts within one mold. It also prevents damage caused by using an incorrect tool when making a mold.

Choosing a suitable CNC tool storage rack is crucial for optimizing workshop organization, improving productivity, and ensuring the longevity of tools. Here are some important factors to consider when selecting a CNC tool storage rack:

Tool Inventory and Capacity:

Determine the number of CNC tools that need to be stored and their sizes. Choose a storage rack with enough capacity to accommodate the entire tool inventory while allowing room for future expansion. Consider the different storage capacities of the CNC tool storage racks, which can be designed to hold large or small tools.

Tool Classification and Accessibility:

Categorize CNC tools based on their types, sizes, or usage frequency. Choose a storage rack that provides clear classification and easy access to tools. Look for features such as labeled tool drawers, perforated tool panels, or rolling tool carts that enable quick identification and retrieval of tools. Some CNC tool storage racks are equipped with wheels, making it easy to move them from one workshop area to another.

Durability and Material:

Select a storage rack made of durable materials that can withstand the demands of a CNC workshop environment. A storage rack made of metal or high-strength plastic is a good choice because it can resist heavy loads, impacts, and the corrosive effects of coolants and lubricants. Ensure the storage rack is sturdy and stable enough to safely store heavy CNC tools.

Space Optimization and Footprint:

Consider the available floor space in the workshop and the footprint of the storage rack. Choose a storage rack that optimizes space utilization without occupying too much floor space. Vertical storage racks or wall-mounted racks may be suitable for workshops with limited space. Some CNC tool storage racks can be customized to fit the specific space and storage needs of different workshops.

Mobility and Flexibility:

If the CNC workshop requires frequent tool relocation or the need to move tools between different workstations, consider a storage rack that offers mobility and flexibility. Look for features such as swivel casters, foldable shelves, or modular components that allow easy movement and adjustment of the storage rack.

Safety and Security:

Ensure that the storage rack has safety features, such as preventing tool slips and accidental falls. Choose a storage rack with edges or tool stops. Additionally, consider the need for tool cabinets with locks to enhance the security of storing valuable or hazardous CNC tools.

Q1: What is a CNC tool storage rack?

A1: A CNC tool storage rack is a dedicated storage system designed to organize and store CNC tools, such as end mills, drills, lathes, and other cutting instruments.

Q2: Why is it important to store CNC tools in a rack?

A2: Storing CNC tools in a rack helps keep them organized, minimizes the risk of damage or wear, extends the lifespan of the tools, and enhances operational efficiency by reducing the time spent searching for needed tools.

Q3: What are some common types of CNC tool storage racks?

A3: Some common types of CNC tool storage racks include vertical racks, horizontal racks, wall-mounted racks, and drawer units, each offering different advantages in terms of space-saving, accessibility, and organization.

Q4: How can a CNC tool storage rack be beneficial in a workshop?

A4: A CNC tool storage rack can be beneficial in a workshop by providing a systematic and organized approach to storing tools, which can improve workflow, reduce downtime, and enhance workplace safety.

Q5: What should be considered when choosing a CNC tool storage rack?

A5: When choosing a CNC tool storage rack, factors such as the type and quantity of tools to be stored, available space, desired accessibility, and budget should be considered to ensure the rack meets the specific storage needs.