CNC Rubber Sheet Cutting Machine: An Overview

The CNC rubber sheet cutting machine is an essential tool for industries requiring precision in cutting rubber sheets for various applications. Utilizing computer numerical control (CNC) technology, these machines ensure that each cut is executed with unparalleled accuracy, allowing manufacturers to achieve intricate designs and consistent results. As industries evolve and demand more specialized materials, the CNC rubber sheet cutting machine plays a pivotal role in fabricating rubber products utilized in automotive, aerospace, and medical sectors.

Types of CNC Rubber Sheet Cutting Machines

CNC rubber sheet cutting machines come in various types, each designed to cater to specific needs and applications. Understanding these types is crucial for selecting the right machine for your business:

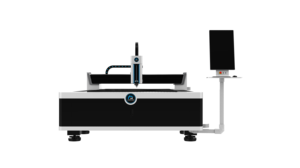

- Laser Cutting Machines: Utilize laser technology to achieve highly accurate cuts, making them ideal for complex designs.

- Water Jet Cutting Machines: Employ high-pressure water streams mixed with abrasive materials to cut rubber sheets, perfect for thicker sheets.

- Drag Knife Cutting Machines: Use a knife that is dragged across the material for high-speed cutting, suitable for thinner rubber sheets.

- Router Cutting Machines: Feature spinning blades that can create detailed custom shapes in thick rubber materials.

Applications of CNC Rubber Sheet Cutting Machines

The versatility of CNC rubber sheet cutting machines allows them to be employed across various sectors. This versatility enhances their utility in differing industrial applications:

- Automotive: Used for making gaskets, seals, and various rubber components.

- Aerospace: Ideal for producing precision parts that require specific material properties and dimensions.

- Medical: Essential for fabricating rubber products such as seals and tubes which require high accuracy and hygiene standards.

- Manufacturing: Commonly utilized in producing mats, flooring, and soundproofing materials that need precise dimensions for effective applications.

Features and Advantages of CNC Rubber Sheet Cutting Machines

The CNC rubber sheet cutting machine is equipped with advanced features that contribute to its efficiency and effectiveness in various applications:

- Precision Cutting: CNC technology allows for precise control over cuts, minimizing waste and maximizing material usage.

- Programmable Controls: These machines can be programmed to follow complex designs, reducing labor costs and time.

- Versatility: Capable of cutting different types of rubber materials, including foam, silicone, and harder rubber composites.

- Automated Process: Reduces manual labor and human error, leading to higher consistency in production.

- Safety Features: Equipped with safety mechanisms to protect operators, ensuring that the working environment remains secure.