(3046 products available)

An essential part of any CNC machine, the router clamp holds the workpiece in the correct position. Although they aim to immobilize the subject, different types of clamps are designed to accommodate other shapes and sizes of materials. Here is a rundown of the most common types of CNC clamps available.

Anchor

The anchor clamp is a mechanical device widely used in CNC routers to provide secure restrictions for uneven workpieces. It consists of an anchor body that exerts force by moving a fastening screw to clamp the workpiece properly. The highlight of anchor clamps lies in its ability to provide stable restrictions, even for workpieces with irregular shapes. This feature ensures that all corners and edges of the workpiece are adequately fixed, thus achieving high-precision processing results.

Disc

A disc clamp consists of two parts: a single clamp and a movable disc. With the movable discs, they can easily and horizontally locate the workpiece without any restrictions to the spindle. Users can reposition the discs to hold workpieces of different lengths. The main bolt also allows vertical adjustment, making it an exceedingly flexible support.

Poly

Poly clamps for CNC machines, also known as polycarbonate clamps, are designed to hold workpieces made of plastic or other lightweight materials. They provide a secure grip without causing damage to delicate or easily marred surfaces. One of the notable features of poly clamps is their transparent appearance, allowing for clear visibility of the workpiece during the machining process. This transparency enables operators to monitor the progress and details of the workpiece while it is being held in place by the clamp.

Side T

A side T also known as a hold-down clamp, is a mechanical device widely used in CNC machine tools to provide stable fixed support for workpieces during processing. The side T clamp consists of a side T-shaped body that exerts force to hold down the workpiece. This design allows the side T clamps to adapt to different sizes and shapes of materials, providing a secure fix. Particularly, it can apply uniform clamping force to the entire area of the workpiece, thus ensuring reliability and stability of fixation.

Top N

A top N, or top-mounted clamp, is a clamp positioned from the top to hold down a workpiece. Unlike side clamps, top clamps apply vertical pressure to fix the workpiece, thus providing stable support from above. This means that top N clamps can be used to fix workpieces of various shapes and sizes, including irregularly shaped workpieces. The top clamps provide flexible fixing methods, which are suitable for different processing needs and occasions.

To buy the right CNC clamps for a buyers' CNC machine, it helps to know the types, specifications, and compatible materials. Here are some common types of CNC clamps, their specifications, and maintenance requirements.

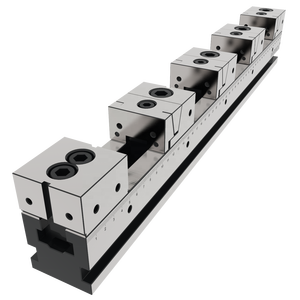

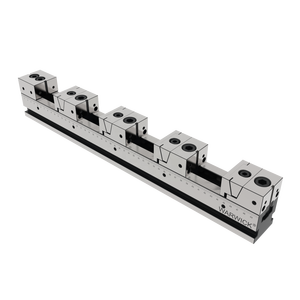

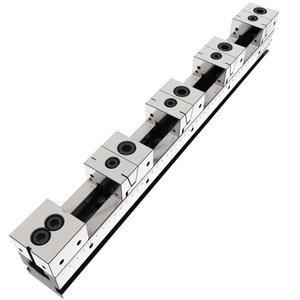

Classic Bench Vise

Its parts include a base, a movable jaw, a fixed jaw, and a spine. The base gets mounted on a workbench. The fixed jaw does not move, while the spine connects the base and the jaw. A classic bench CNC router clamp holds round stock. It can also hold large and irregularly-shaped workpieces.

Maintenance: To ensure longevity, users should clean the clamp regularly to remove any debris and dust. They should also wipe any oil from the clamp after use to prevent any damage to the workpiece. Store the clamp in a dry place to avoid rust. When overtightening, be careful not to damage the workpiece jaw lining. Lubricate the movable part and the threaded rod regularly to maintain smooth movement.

Rubber Padded Clamp

This type of CNC routing clamp applies even pressure to hold a workpiece. It comes with rubber padding on the fixed jaw. The padding prevents damage to the workpiece. The clamp is an affordable solution for those who want to use pads without breaking the bank.

Maintenance: Users should keep the clamp dry to avoid rubber padding deterioration. Use lubricant oil to coat the movable jaw and screw threads. When done, wipe excess oil to prevent damage to the workpiece.

Quick-Release Clamp

A quick-release CNC clamp is ideal for a user who needs to secure and release a workpiece quickly. To tighten or loosen a workpiece, pull the trigger or press the button. This clamp applies consistent force in all directions.

Maintenance: Before storage, clean debris and dust from all clamp parts. Use oil to coat movable parts and exposed threads to enhance longevity and smooth movement.

Deep Throat C-Clamp

A deep throat C-clamp has an open frame that allows access to the workpiece from different directions. It is a versatile CNC router to hold down clamp that exerts ample pressure on a tarot or thick workpiece, making it sit flush on the CNC bed. It allows for accurate cuts.

Maintenance: Clean the clamp after each use to remove dust and debris. Lubricate all moving parts to keep the clamp working properly. Wipe off excess lubricant before storage to prevent dirt build-up on the clamp.

Friction-Retained Clamp

A friction C clamp works by adding force with a threaded shaft. The CNC clamp, secured at the bottom by friction, holds a workpiece in different orientations. It is affordable and easy to use. A disadvantage is that it may lose clamping force due to friction wear over time.

Maintenance: Regularly clean the base to remove debris and dust. Periodically assess the wear and tear of the friction surface and replace it as needed. Lubricate the moving part and the threaded shaft to prevent excess strain and friction damage.

Magnetic Clamps

A CNC magnetic clamp uses magnetic force to hold down metallic workpieces. It provides easy access from all sides of a workpiece. Users can position and replace a workpiece quickly without adjusting the clamps. To release the workpiece, simply push the switch to turn off the magnetic.

Maintenance: Magnetic clamps require minimal maintenance. But users should clean the clamp surface to remove debris and dust. Store the clamp in a dry area to protect the magnetic from damage.

CNC clamps for holds workpieces firmly in place while the CNC machine cuts or carves the material into the desired shape. However, woodworking clamps have varying applications in different industries.

In the Manufacturing Industry

CNC router clamps are essential devices in the manufacturing industry. These devices hold part works with precision as they get cut or engraved by a computerized machine. The use of clamps ensures that the final production is of high accuracy and quality.

In the Furniture Making Industry

CNC router clamps are commonly used in furniture production to secure wood planks while they are being cut or engraved. This type of clamp is useful for creating decorative pieces such as carvings, moldings, letters, and designs.

In the Sign-Making Industry

The Sign-Making industry often uses CNC Router to create well-braced works with letters, logos, and graphics. As a result, the application of these routers gives a smooth and high-quality finish to the machine-made signage.

In the Aerospace and Automotive Industries

In the Automotive and Aerospace Manufacturing industries, the CNC machine-cut materials include plastic, carbon fiber, and aluminum. Yet, these workpieces need to be held down while the router machine cuts them with precision. Therefore, the Clamp is needed as a fixture to hold the material steady, allowing the CNC machine to achieve accurate and clean cuts.

Here are things to consider when selecting a CNC router clamp.

Q1: What are CNC clamps used for?

A1: CNC clamps are useful accessories for holding down material during the machining process. They provide a temporary holding solution that allows the workpiece to be held from any angle.

Q2: How do CNC router clamps work?

A2: CNC clamps are placed around a workpiece and tightened to apply friction and hold it in place. Some types of clamps may require tool fitting, while others come with a quick-release mechanism for faster operation.

Q3: What are the benefits of using CNC clamps?

A3: CNC router clamps offer the benefits of compatibility with various materials and shapes, cost-effectiveness, protection of workpieces, ease of use, and adaptability to different projects and machining needs.

Q4: What are some limitations of CNC clamps?

A4: Although CNC clamps are great at providing support for irregular shapes and lower costs, they are not suitable for providing the same level of force or stability as fixed jigs and may require frequent setups and adjustments.