(2528 products available)

A CNC rapid prototyping maker utilizes a variety of materials, including:

Plastics

Plastic is one of the most common materials utilized in the CNC rapid prototyping maker process. This is primarily due to the ease of handling and the cost aspects. CNC machines offer great accuracy when working on plastic materials such as ABS, acrylic, and polycarbonate. These materials are usually chosen because they are easily processed into complex shapes and structures. Moreover, they are lightweight and durable. CNC machining of plastic prototypes happens to be much more more cost effective than producing the same prototypes in production-grade molds.

Metals

Metals like aluminum, brass, and stainless steel are also used despite the relatively higher costs. CNC machines provide unmatched precision in cutting and shaping these metal products. This makes it a preferred choice in industries such as automotive and aerospace, where high-strength prototypes are required. Aluminum, for example, is widely used in prototyping due to its strength and corrosion resistance. CNC machining of metal prototypes also provides a close tolerance which are critical for functional components.

Composites

CNC rapid prototyping makers are designed to work with foam, fiberglass, and carbon fiber composites. These materials are usually light in weight, but they provide exceptional strength. This makes them ideal for use in highly demanding applications. This capability enables manufacturers to create prototypes that mimic the performance characteristics of the final product. This is especially important in industries like marine, automotive, and aerospace, where weight and strength are critical factors.

Wood

Machineable woods mainly include plywood, MDF, and hardwoods like cherry. This makes them highly suitable for CNC prototyping in the woodworking industry. The choice of wood material is specifically dependent on the prototype application. This is chiefly because wood offers a natural aesthetic appeal and structural integrity, which makes it widely used in furniture and interior design prototypes.

Styrene Ethylene Butylene Styrene

Commonly known as SEBS, styrene-ethylene-butylene-styrene is a thermoplastic block copolymer elastomer. It is gaining popularity for its durability, flexibility, and suitability for CNC machining. These properties make it highly suitable for creating prototypes requiring impact resistance and a soft feel. Being a non-toxic material, SEBS is also used for products that are intended for human interaction.

Product Development

The CNC rapid prototyping maker is used in product development to create highly accurate prototypes from a diverse range of materials. These materials include plastics, metals, and composites. The CNC machines work by slicing the material in a highly precise manner to develop prototypes that reflect the design intent. This is great as it helps companies to test the shape, fit, and functionality of their ideas before venturing into mass production. With CNC prototyping, manufacturers are able to fast-track their product development cycle. This sometimes means that products are taken to market much faster than their competitors.

Aerospace and Automotive Industries

CNC rapid prototyping is extensively used in these two industries, where prototypes are required for testing. These prototypes can be used to test components such as engine parts, fuselage sections, and interior fittings. The high precision of CNC machining ensures that aerospace parts prototypes will meet the stringent safety and performance standards required by regulatory agencies. Automotive engineers mainly use CNC prototypes to evaluate the design and functionality of critical components. This includes testing the structural integrity of prototypes of the chassis and other components under stressful conditions.

Medical Applications

Prototypes of medical devices offer an analysis of how they are to fit and work in the real-life scenario. CNC rapid prototyping makers produce prototypes of instruments, implants, and devices with a level of precision that is critical in medical applications. Prototypes of implants such as joint replacements can be tested for compatibility and functionality before attempting to make the actual product. This reduces risks associated with surgery and improves patient outcomes. Additionally, prototypes of medical devices are used for training purposes, enhancing the quality of medical education.

Architecture and Construction

The building industry is also taking CNC rapid prototyping makers. The models produced are precise and help in conveying the design concepts more accurately. They are used to create prototypes of building components such as roofing, facades, and structural elements. These prototypes help architects and builders to a greater extent evaluate the design aesthetics and practicality. This results in better adherence to the design philosophy and a reduction in errors during the construction process.

Consumer Electronics

The CNC rapid prototyping makers are used to design casings, internal components, and other parts of consumer gadgets. The high level of precision that CNC machining brings is useful when dealing with components that need to fit together with high accuracy. For instance, smartphones and laptops prototypes are developed using CNC prototyping to test ergonomics and functionality. This allows electronics companies to iterate on their designs quickly. Henceforth, minimizing time-to-market for popular products.

Ensuring the quality of CNC machines can be addressed by looking at the following factors:

Material Selection

Using high-quality materials for both the machinist and the prototype is a good way to ensure quality. This includes choosing the right type of metal, which would be either aluminum or steel, and the right type of wood, which could be plywood or hardwood. Using quality materials contributes to durability and functionality.

Machine Calibration

Proper machine calibration is done to ensure that the machine performs optimally and prototyping yields quality prototypes. CNC machines should regularly be maintained and serviced. This includes checking the precision of the tools and the machine. Any deviation from the design could affect the quality of the prototype.

Prototyping Process

During the prototyping process, the designer should pay a close look to the initial stages and ensure the machine is set up correctly. The CNC program should also be verified to confirm that it matches the intended design. Frequent checks during the early stages of machining can help identify issues such as incorrect tool paths or settings.

Visual Inspection

A visual prototype inspection should be conducted throughout the machining process. This helps in identifying visible issues such as burrs, rough surfaces, or incorrect dimensions. Checking against a set standard or the blueprint should be done to ensure adherence to specifications. Any discrepancies should be dealt with as soon as they arise rather than assuming them.

Dimensional Verification

Using precision measuring tools such as calipers and micrometers should be conducted to validate the dimensions of the prototype once it is fully developed. Comparison of the measurements obtained with the original design specifications goes a long way in ensuring the quality of the prototype is up to standard. In case of any discrepancies, adjustments should be made accordingly. This happens mostly before proceeding with additional prototypes or production runs.

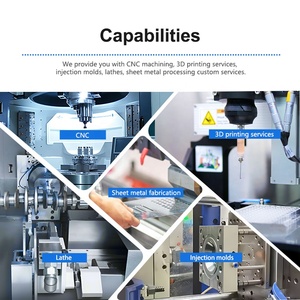

When choosing the CNC prototyping maker, there are a number of things that a buyer should consider.

Material Compatibility

The CNC rapid prototyping maker should be able to work with a wide range of materials, including plastics, metals, and composites. Different projects may require different materials; hence the compatibility of the machine with the materials will determine its versatility. The machine should also handle the material that is mostly used in one’s production.

Precision and Accuracy

One of the most crucial factors in CNC rapid prototyping is the level of precision it can achieve. The accuracy of the machine is responsible for the quality of the prototype it produces. Check on the machine's specifications for details on its resolution and tolerance. Generally, machines with smaller stepper motors provide a finer resolution. Customers can also ask for samples to be produced by the machine to check the precision and quality.

Machine Size and Workspace

Machine size is an important factor, especially when working on large prototypes. The workspace of the machine should be large enough to accommodate the size of the prototype. On the other hand, large CNC machines are suitable for large projects, while small ones are suitable for small, detailed work. Also, consider the space available in the workshop for the machine.

Software and Control

CNC machines are controlled by computer software. Thus, the design and ease of use of the software associated with CNC machines are of great importance. This software should allow easy import of designs from other software. Also, the software should be user-friendly for people with little knowledge of CNC machining. It should also be compatible with major design software to prevent switching the designs because of incompatibility.

Budget and Costs

Budget and costs are one of the most important factors when choosing a CNC machine. High-precision prototyping machines come with a cost while low-cost machines may compromise on precision and build quality. It might be tempting to go for the lowest-priced products, but one should consider the long-term expenses as well. Costs for maintenance, operation, and potential repairs should also be factored in.

Reviews and Support

Look for reviews from other users to have an empirical understanding of the machine's performance. Primary feedback usually provides insight into the machine's reliability, precision, and ease of use. One should also consider a machine that has good after-sales support. This ensures that in case there are issues or questions, one can get timely assistance.

A1: It is the process of creating physical models from digital designs using computer-controlled tools.

A2: CNC machines commonly work with plastics, metals, wood, and composites.

A3: These include the aerospace, automotive, medical, architecture, and consumer electronics industries.

A4: Precision is the only difference since CNC machining is computer-controlled while traditional is manual.

A5: Material compatibility, precision, software, and budget are important factors to consider when choosing a CNC rapid prototyping maker.