(6194 products available)

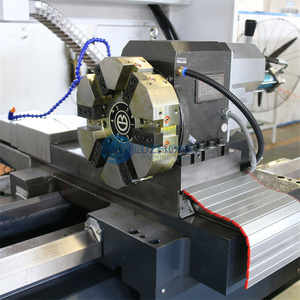

CNC machines are programmed and controlled by computer software, ensuring high levels of precision and automation in the machining process. There are several types of low-cost CNC machines, such as CNC milling machines, routers, plasma cutters, etc.

Workpiece Diameter

It indicates the permitted diameter of a workpiece. For instance, it is common for an entry-level benchtop lathe to have a maximum workpiece diameter of around 6 to 12 inches.

Workpiece Length

It defines the permitted length of a workpiece. A low-cost lathe may support a workpiece length ranging from approximately 8 inches to over 24 inches.

Power Rating

It determines the motor power, which directly affects the machining capacity. The power rating of a low-cost machine tool may be around 0.5 to 2 horsepower.

Speed Range

A low-cost lathe usually possesses several rotational speeds. The speed range may be 50 to 3,000 or 5,000 revolutions per minute (rpm).

Control System

The CNC system is usually a key characteristic of a low-cost CNC lathe. The control system may use economical and simple-to-learn CNC controllers, such as an embedded CNC, G-code controllers, or others.

Regular cleaning

Use a soft brush and cloth to clean the dust and chips on the lathe. Then, clean the CNC system and electric cabinet with a vacuum cleaner. Ensure no debris remains in the vicinity of the electrical components to prevent electrical fires.

Lubrication

Apply proper oil to each lubrication point of the lathe according to the CNC machine lathes' maintenance manual to ensure smooth operation of the guide rails, racks, and other parts.

Check

Regularly check the fasteners and prevent them from loosening. Pay attention to the alignment and fitting of the sliding parts and adjusting components to ensure they are not too tight or too loose. Check electrical connections and cables to ensure they are not loose or out of the way.

Pay attention to the cooling system

Ensure the coolant's level and temperature are maintained. Regularly check the coolant pump and cooling fan to ensure they operate properly.

Dust and moisture prevention

Close the protective cover of the lathe and the doors of the electric cabinet while not using the lathe to prevent dust and moisture from getting inside.

Traditionally, lathes rotated workpieces against stationary cutting tools. Modern CNC machines accomplish the same goal with greater control and precision. With proper programming, a low-cost CNC lathe machine can cut materials into threads, grooves, arcs, and complex circular shapes. As mentioned before, low-cost CNC lathes are better suited for making smaller parts from softer materials.

Grocery stores and supermarkets around the world have aisles filled with products manufactured by low-cost CNC lathes. Everyday products like toothbrush handles, spinning tops, knob and valve handles, salt and pepper shakers, game controllers and joysticks, hair combs, light fixture components and many more all contain parts made by CNC lathes!

Motor and bicycle retailers can't afford to ignore the usefulness of the CNC lathe. Low-cost CNC lathes make it easy to create motor components, bike spokes, grips, wheel hubs, pedals, axles, and more. They are a perfect combination of speed and accuracy when working with metal and plastic. Low-cost CNC lathes also produce parts for other kinds of vehicles, such as tractors, that require simpler designs.

In the jewelry world, every goldsmith, silversmith, and jewelry designer know how crucial a CNC machine is to their work. When it comes to complicated patterns, precise cuts, and delicate engravings, gold, silver, and precious stone jewelry pieces are only some of the jewelry that needs an accurate and low-cost CNC lathe.

Nature and Size of Business:

When deciding whether to get a low-cost CNC lathe machine, the kind of work one does should matter. If one regularly makes things with a common type of metal or plastic, a budget-friendly CNC machine could work fine.

Cost of CNC Machines:

A cheap CNC lathe is one that costs less to purchase, use, and keep over its lifespan. Costs vary widely, so it's smart to look beyond the initial cost to see how much it will really cost in the years ahead.

Replacement Parts and Service:

Ensure that repair and maintenance needs are met. Low-cost CNC lathes have fewer features, but getting parts and service should still be easy. Check that local suppliers or service providers can find replacement parts and offer support if something goes wrong with the machine. This saves time and money spent troubleshooting solutions that are far away.

Age of the CNC Machine:

It's best to buy low-cost CNC lathes that are not too old, as this may make finding replacement parts more difficult. Machines with more common, newer components will allow for faster, simpler repairs. The providers will also already be familiar with the CNC machine. This speeds up service and support whenever needed, allowing the business to run efficiently with less downtime for repairs.

Operator Skills:

Simple designs that only do basic functions are usually best when looking for a low-cost CNC lathe. These machines will have fewer features, but they will be easier for operators who do not have advanced skills to use. While more complex machines offer greater abilities, their intricacy requires more trained knowledgeable staff. Putting budget constraints first means prioritizing simpler, more basic models that low-skilled workers can operate without needing special training or certifications.

Q1: Are low-cost CNC machines worth it?

A1: In general, a low-cost CNC machine is worth it because it provides an inexpensive entry point into CNC technology. With a CNC machine, users will enjoy automation, increased accuracy, and reduced labor. However, it is advisable to consider material compatibility and desired application before purchasing a low-cost CNC machine.

Q2: What is the smallest CNC lathe?

A2: The CNC Micro Lathe is regarded as one of the smallest CNC lathes in existence. This small machine can work with stock up to 1'' in diameter.

Q3: How long does it take to learn CNC machining?

A3: In most cases, learning CNC programming can take between 6 months to 2 years, depending on the type of CNC machine and the specific programs. However, many CNC operators learn the basics in less than a year and land a job soon after their training.

Q4: Can I learn CNC at home?

A4: In most cases, learning CNC at home is possible. There are many online resources that aspiring CNC operators can use to learn more about the machine. However, since CNC machines are difficult to operate, it is advisable to enroll in a formal training program before attempting to use the machine at home.