(14817 products available)

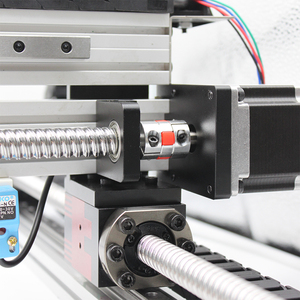

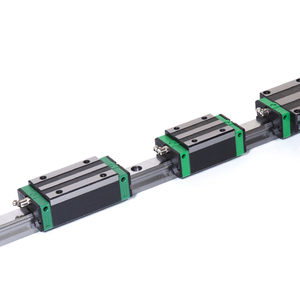

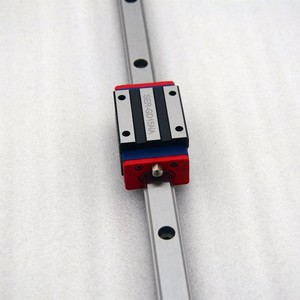

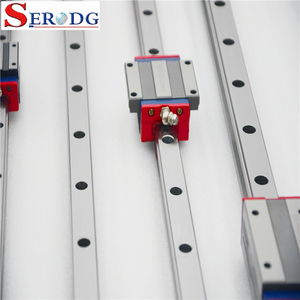

CNC machine linear motion guideways are the components that allow linear movements. With the increasing popularity of precise machining needs, there has been a growing demand for durable, stable, and precise guide rails. These guideways provide surface support for objects that need to slide, usually in a straight direction.

Following are the key specifications related to the Linear Motion Guideway CNC machine:

Maintenance:

Due to their multiple benefits, CNC linear motion guideways have multiple applications for both functional and industrial purposes.

Robotics:

CNC linear motion guideways are commonly used in robot joints and arms to allow the robots achieve precise motions and great load capacity. They also enable the easy assembly of heavy objects.

Medical Devices:

Medical instruments and equipment need to be highly precise so that doctors can offer excellent healthcare to their patients. Also, some medical equipment, such as wheelchairs, requires smooth motion. Therefore, guideways are used in various medical devices to ensure smooth, accurate, and dependable motion.

Aerospace:

In the aerospace industry, motion linear guides are used in various applications, such as assembly jigs, gantries, and tool changers. This is because the component requires a system that can guarantee accuracy while withstanding harsh environments and heavy loads. The durability and precision nature of motion linear guides makes them well-suited for these applications.

Automotive Industry:

As cars become fancier, the industry requires tools that can grant smooth, fast, and precise operations. Linear motion guideways are present in car manufacturing processes and automation equipment. They improve the accuracy of CNC machines, thus enhancing car production.

Textile Industry:

In the textile industry, linear motion machines assist in automating processes, cutting materials, and creating precise patterns. This improves efficiency and precision in textile production. Also, their durability and precision-guiding characteristics under heavy loads make them suitable for textile machine operations. Now, companies can achieve smoother, faster, and more accurate textile production.

The following are some important factors to consider when selecting a linear guideway for a CNC machine.

Matching Load Capacity and Rigidity

It's essential to determine the load capacity and rigidity of the linear motion guideway to ensure they match the machine's requirements. Consider factors such as the weight of the payload, including any additional tooling or fixtures, and the rigid linear guide rails and blocks are chosen to support the machine's motion without introducing excessive deflection or vibrations.

Precision and Accuracy

Selecting a guideway system that provides the required level of precision and accuracy for the application is fundamental. Consider the tolerance levels, straightness, and flatness of the guideway, as well as the resolution and repeatability of the associated positioning components. Ensure that the chosen linear motion guideway allows for precise and repeatable motion control essential for achieving desired machining accuracy and quality.

Environmental Considerations

Environmental factors can significantly impact the performance and longevity of linear motion guideways. Consider the specific environmental conditions in which the guideway will operate, such as exposure to dust, debris, moisture, temperature extremes, or corrosive substances. Select appropriate protective features, such as seals or covers, to prevent contamination and consider materials and lubrication options that can withstand the expected environmental challenges.

Assembly and Maintenance Requirements

When choosing a linear motion guideway, assembly and maintenance considerations are crucial for ensuring smooth installation and long-term reliability. Opt for guideway systems designed for straightforward assembly, minimizing complexity and downtime. Additionally, select guideways that allow for simple periodic maintenance, such as lubrication points or accessible components, to facilitate routine servicing and maintain optimal performance over time.

Q1. What is the difference between a linear motion guide and a linear motion guideway?

A1. The term "linear motion guide" typically refers to a broad category of components that facilitate linear motion. This includes various systems like rails, slides, and bearings. On the other hand, a "linear motion guideway" is a specific type often used in machine tools and CNC machines to refer to the rail-and-bearing system that allows for precise linear motion along a designated path.

Q2. What are linear guides in CNC machines made of?

A2. Linear guides in CNC machines can be made from a variety of materials to suit different applications and requirements. The most common material for linear guides is high-carbon steel, often used for its strength, durability, and wear resistance. Sometimes, such as in applications requiring reduced friction and longer lifespans, steel guides may be coated with materials like chrome to enhance corrosion resistance and wear resistance. Alloy steel is another option, often chosen for its improved mechanical properties.

For applications requiring lightweight components, aluminum alloy is sometimes used as a material for linear guides, although it's less common in heavy-duty CNC machines. Aluminum linear guides are lighter but still provide sufficient precision and accuracy for non-industrial-grade CNC machines. Regarding the rolling elements, they typically use high-quality steel or ceramic materials, precisely manufactured and treated to provide optimal performance, minimal friction, and maximum durability.

Q3. How to install linear motion guides?

A3. Installing linear motion guides requires careful preparation, planning, and sometimes alignment tools. The process may vary depending on the type of linear guide and equipment being used, but the following steps provide a general guideline for the installation.

The installation may involve securing methods, such as screws, bolts, or clamps, and precise torque specifications per the manufacturer's instructions. Checking alignment after installation is crucial to ensuring the component correctly holds. Other alignment tools may be used, such as straight edges, levels, or laser alignment tools.