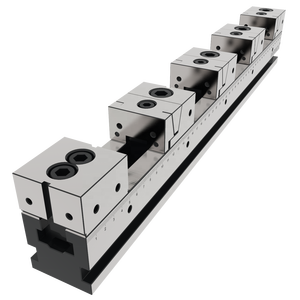

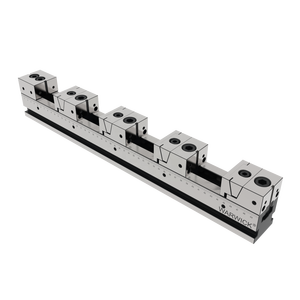

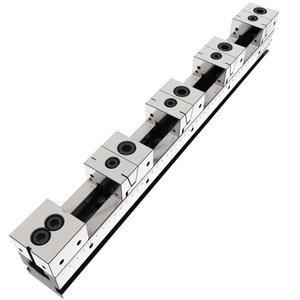

CNC Hold Down Clamps: An Introduction

CNC hold down clamps are essential tools used in various machining operations to securely fasten workpieces to a CNC machine's table. These clamps provide the stability needed to ensure precision and accuracy during the cutting, drilling, or milling processes. With a variety of designs available, CNC hold down clamps are favored among manufacturers and hobbyists alike for their versatility and efficiency.

Types of CNC Hold Down Clamps

Understanding the various types of CNC hold down clamps is essential for selecting the right fit for your projects:

- Standard Clamps: These are the most commonly used clamps, offering basic functionality for fastening workpieces during machining.

- Toe Clamps: These clamps have a unique design that aids in securing irregularly shaped pieces without damaging the surface.

- Quick-Release Clamps: Ideal for operations requiring frequent adjustments, these clamps can be easily and quickly released and adjusted.

- Pneumatic Clamps: Utilizing compressed air for operation, these clamps provide consistent pressure and are perfect for high-volume production settings.

Functionality and Features of CNC Hold Down Clamps

CNC hold down clamps come equipped with numerous features that make them indispensable in machining:

- Precision Fit: Designed to hold workpieces securely, minimizing movement during machining.

- Adjustable Pressure: Many models allow for the adjustment of clamping force to protect sensitive materials.

- Easy Setup: Most CNC hold down clamps are designed for quick installation, reducing downtime in production.

- Material Conformity: Some clamps have padding or coatings to protect delicate surfaces from scratches and dents.

Advantages of Using CNC Hold Down Clamps

Choosing CNC hold down clamps for your machining processes delivers a range of benefits:

- Enhanced Stability: Firmly securing workpieces increases precision and reduces the risk of errors during manufacturing.

- Time Efficiency: Quick-release mechanisms and easy setups help shorten cycle times on the production floor.

- Durability: Made from high-quality materials, these clamps can withstand repetitive use and harsh machining environments.

- Versatility: Suitable for a range of applications, from woodworking to metalworking, ensuring adaptability to various projects.

Applications of CNC Hold Down Clamps

CNC hold down clamps are widely utilized across different industries, including:

- Woodworking: Essential for securing panels, boards, and intricate designs while cutting or engraving.

- Metal Fabrication: Hold down clamps are vital for machining metal pieces during milling, drilling, and grinding processes.

- Aerospace Manufacturing: The clamps ensure extremely precise cuts, vital for components subjected to rigorous standards.

- Prototype Development: Ideal for ensuring prototypes maintain their shape and precision during initial machining.