All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(36310 products available)

A CNC boring machine's primary purpose is to create accurate holes in wood and other materials. However, with the integration of computer numerical control (CNC) technology, which utilizes a computer program for automation, there is now a wide variety of types of CNC boring machines.

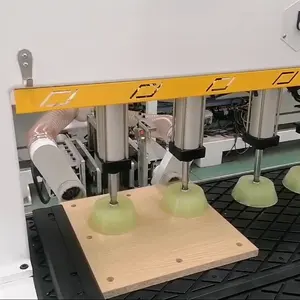

CNC Boring Machine with Multiple Spindles:

One popular type of CNC borer features a carousel with a series of spindles, each equipped with different drill bits. This machine automatically rotates to the next spindle whenever a new hole needs to be drilled. The spindle performing the job at that moment will then be the one coming into play.

The use of several spindles in carousels allows this kind of boring machine to complete numerous drilling operations in a single work cycle, which increases productivity and shortens processing time.

Multi-spindle CNC boring machines usually come with touch screens and other user-friendly interfaces, which makes their operations and controls quite convenient and simple. Operators have the option of changing the spindle's rotation speed and drilling depth, among other settings. This is regardless of the workpiece's form or complexity.

CNC Boring Machine with Horizontal and Vertical Drilling:

CNC boring machines that can drill both horizontally and vertically are another popular variety. Such machines are designed to easily accommodate workpieces of varying sizes and shapes by providing them with a wide range of drilling operations and combinations.

These machines feature vertical and horizontal drilling heads. It is now possible to drill holes in a workpiece from various positions and orientations. As a result, it is easy to perform more complex hole patterns and arrangements.

Flexibility is one of the greatest advantages of this kind of CNC boring machine. It can be used for a variety of tasks such as making joints, installing hardware, creating intricate designs, and more. Additionally, because there is no need to reposition the workpiece between multiple machines, the combination of vertical and horizontal drilling saves time and increases efficiency.

Deep Hole CNC Boring Machine:

Specialized drilling machines called deep hole CNC boring machines are built for drilling deep holes with a precise diameter into a workpiece. They stand out for their capacity to drill deep holes through a workpiece to a precise depth while maintaining accuracy and uniformity.

Deep hole boring machines use a variety of boring processes to achieve deep hole machining. Among them are the use of replaceable boring bars and head attachments as well as the "through spindle" boring technique, which involves directly passing the drill bit through the spindle of the machine.

In addition, deep hole CNC boring machines may have cooling and chip removal systems for more effective machining. These ensure accurate cutting during the entire process and also control the temperature of the workpiece to prevent it from warping or being damaged.

The specifications of a CNC borer will vary depending on the machine type, model, and brand. Generally, a CNC borer's cutting diameter ranges from 30mm to 5000mm. Three to five axis CNC boring machines are prevalent, and their axis quantity will vary with specific machines. The maximum cutting depth of a CNC borer generally ranges from 30mm to 3000mm pure machining depth. The spindle speed usually ranges from 500rpm to 8000rpm. The boring machine's maximum weight capacity ranges from 50kg to 30000kg, with a machining accuracy between +/- 0.01mm and +/- 0.001mm.

The maintenance tips for a CNC boring machine include the following:

Woodworking industry

CNC wood boring machines create holes for joints, hinges, dowel insertion, and decorative elements in wood assemblies. They provide precise and consistent results, helping to improve the quality of woodworking projects.

Cabinet manufacturing companies

CNC boring machines for cabinets automate the process of drilling holes for shelves, hinges, drawer rails, and other hardware components. Their use enhances production efficiency, accuracy, and the overall quality of cabinets.

Furniture production facilities

These machines can be used to drill precise holes for joints, fasteners, and upholstery elements such as tufted furniture. Boring machines improve precision and consistency and streamline production processes in the furniture industry.

Musical instrument manufacturers

A CNC instrument-boring machine is a standard tool in a musical instrument workshop. It can create precise holes in musical instruments such as flutes, woodwinds, and string instruments.

Metal fabrication shops

CNC metal boring machines drill holes in metal parts and assemblies for fasteners, bearings, and ventilation or for custom designs. Their use improves accuracy and productivity in metalworking.

Consideration of Workpiece Configuration

A critical aspect in selecting a CNC boring machine lies in the workpiece shape and size. Various industry sectors utilize disparate shapes and dimensions, which impacts the choice of a CNC boring machine. It's crucial to opt for a device that accommodates the workpiece's dimensions. Also, consider its configuration pattern, particularly its cavities and apertures. A workpiece featuring complex interiors and narrow spaces may necessitate an exceptional boring tool to enhance machining efficacy.

Focus on Machining Accuracy and Speed

For businesses where output and precision are paramount, it's vital to opt for a CNC boring machine that guarantees high accuracy and rapid processing speed, thereby meeting production demands. If a significant number of identical workpieces need to be processed consecutively, consider a boring machine with automatic tool change and workpiece clamping functions. These machines can automatically adjust the machining tools and fixtures during operation, thereby enhancing processing efficiency and saving time.

Tool Requirement

Different CNC boring machines are equipped with distinct types and quantities of tools, which will influence their machining capabilities and versatility. A machine with a wider selection of tools can accommodate more machining requirements. Additionally, the tooling's quality plays an essential role in machining effectiveness, hence the importance of selecting durable, high-performance tools.

Operational Simplicity and Control System

Selecting a boring machine with a straightforward manipulation process and an understandable control system can lessen the necessity for operator training and expedite operational processes. Also, consider the machine's maintainability and the accessibility of replacement parts. Choosing a device that is easy to maintain helps to ensure that it remains operational for extended periods.

Consideration of Budget Constraints

Finally, taking into account the budget limitations is critical. CNC boring machines come in diverse types with a wide range of prices. It's crucial to select a device that aligns with specific needs and financial resources. While considering the budget, also take into account the long-term operating costs, including energy consumption, tool replacement, and maintenance expenses.

Q1 What are the benefits of using CNC boring machines?

A1. CNC boring machines offer some advantages. The first one is that all operations can be done in one setting, which means a high level of precision and accuracy. Another benefit of CNC machines is increased efficiency which is attributed to the automation of the machine. Lastly, CNC boring machines allow for complex shapes and designs to be created with ease.

Q2 What are some features of CNC boring machines?

A2. A typical CNC boring machine has a powerful spindle for handling tough boring tasks. It also has a hold system for clamping workpieces to prevent movement during boring. Other features include a coolant system, tool changers and boring bars.

Q3 How big is the CNC boring machine market?

A3. According to a report, the global CNC boring machine market size was USD 1.09 billion in 2022 and is projected to grow from USD 1.15 billion in 2023 to USD 1.51 billion by 2030.

Q4 What are the most popular types of CNC boring machines?

A4. The vertical CNC boring machine is the most popular type because it has an easy-to-operate design. Other popular types include horizontal CNC boring machines and universal CNC boring machines.