All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(5286 products available)

Circular sawmill blades are essential components in the lumber industry, designed for efficient and precise cutting of wood. These blades come in various sizes, including 48 inch circular sawmill blade, 36 inch circular sawmill blade, and up to a 60 inch circular sawmill blade, catering to different sawmill capacities. The selection of a blade is critical, as it directly impacts the cutting process and the quality of the lumber produced.

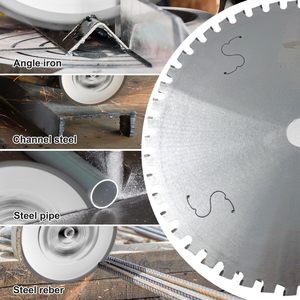

The variety of circular sawmill blades includes options like the 56 circular sawmill blade and 24 inch circular sawmill blade, each suited for specific sawmills and cutting requirements. Larger blades, such as the large circular sawmill blade, are typically used in industrial settings for high-volume lumber processing, while smaller blades may be found in more compact sawmill operations. The application of these blades ranges from cutting softwood to hardwood, and they are integral parts of the sawmill with circular blade systems.

Circular sawmill blades are crafted from robust materials to withstand the rigors of sawmilling. The circular sawmill teeth are often tipped with carbide or other hard materials to maintain sharpness and durability. The design of these blades ensures that they can handle the demands of cutting through various wood types, from hard, dense woods to softer varieties, without compromising on precision.

Each size and type of circular sawmill blade offers unique advantages. For instance, a 30 inch circular sawmill blade provides a balance between size and maneuverability, making it a versatile choice for many sawmills. On the other hand, a 52 circular sawmill blade might be preferred for its larger diameter, which can cut through thicker logs. The choice of blade size should align with the sawmill's operational needs and the type of lumber being processed.

When choosing a circular sawmill blade, it is important to consider the sawmill's specifications and the desired outcome. Factors such as the diameter of the blade, the number of teeth, and the material of the teeth contribute to the overall performance of the sawmill. Additionally, the compatibility of the blade with the circular sawmill parts is crucial to ensure seamless operation and to minimize downtime due to maintenance or blade replacement.

In conclusion, the circular sawmill blade is a pivotal tool in the lumber industry, with a range of sizes and types available to meet various cutting needs. Understanding the features, materials, and advantages of each blade type helps in selecting the most appropriate blade for a given sawmill operation. While the selection process can be complex, the right blade will significantly enhance the efficiency and quality of the lumber milling process.