(1605 products available)

Circular formwork for concrete is used to provide shape and support to building structures made of concrete. There are different types of formwork for concrete construction, and each is used for different purposes. Here are some types of formwork used in concrete construction:

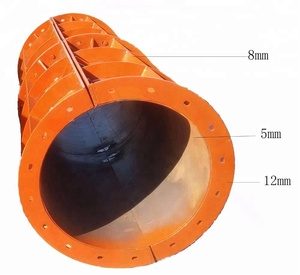

When looking for formwork for sale, it is important to know the functions and features of each. Here are the functions and features of circular concrete shuttering.

This is a feature of formwork that gives it the ability to create round concrete shapes. Its primary function is to take the architectural design of the concrete project into consideration.

This feature is important to mention when discussing circular formwork for concrete. The function of this feature is to support the concrete column or beam. It is a feature that is versatile and can be adjusted to fit any shape of a column or beam, whether it is round, square, or any other shape.

This is a feature that is worth mentioning when talking about circular formwork for concrete. The primary function of this feature is to make sure that the walls are curved. It is adjustable and can be made to fit any curve of a wall.

This is the most important feature of circular formwork for concrete. The function of this feature is to conform to the unique shape of the concrete structure. This is important because all the other features are dependent on this function.

This is a function of circular concrete formwork that allows it to support itself so the concrete can be poured into it. This is an important feature that is used to support a concrete structure until the concrete is set.

This is a function that ensures that circular concrete formwork is strong and can hold the weight of the concrete. It is a feature that is used to ensure that the formwork is strong and can last for a long time.

This is a feature that is important to mention when discussing circular formwork for concrete. The function of this feature is to make sure that it can be adjusted to fit different sizes and shapes of concrete structures. This is important because different projects will require different shapes and sizes of formwork.

This is a function that allows for the use of circular concrete formwork in multiple projects. This is important because this feature allows the user to save money on materials and time. This is an important feature of a formwork that is environmentally friendly.

Circular concrete formwork is the ideal tool for constructing round structures. It provides important support to the wet concrete. The following are the applications of concrete circular formwork:

When buying circular concrete formwork, there are several things to consider to ensure construction projects are done safely, accurately, and efficiently. Here are some of them:

Look for formwork materials that can be reused several times without compromising quality and structural integrity. Most projects require strong and durable materials to provide the necessary support for concrete. Check for weather resistance, as this has a significant impact on the formwork's lifespan and performance.

When choosing circular formwork for concrete, consider the size range and design flexibility. This means selecting a size that matches the project’s requirements. Also, choose adjustable formwork to cater to various diameters and heights.

Choose a circular concrete formwork that is easy to assemble, disassemble, and handle. Look for intuitive designs that require minimal training and supervision. Also, check the weight to ensure it’s manageable during transportation and installation.

Consider the quality of the finish when choosing a circular concrete formwork. Look for smooth and even finishes to minimize the need for additional surface treatments. This eliminates extra labor and time, which eventually lowers the construction cost.

Choose a circular concrete formwork that comes with different accessories, like alignment systems, which help to position the formwork accurately. This ensures uniform concrete thickness and shapes.

Look for formwork that is designed for multiple uses. This helps to cut down waste and costs for each project. Reusable formworks are environmentally friendly, making them an excellent choice for sustainable construction projects.

Q1: Which is better for a circular concrete stairwell, steel or wood formwork?

A1: Steel formwork is more suitable than wooden formwork for curved staircases because it can be customized to any radius and is reusable. Steel formwork is preferred for concrete staircases that are circular because it provides a smooth finish and can be used multiple times. Steel formwork is more expensive than wood but provides long-term cost savings over time.

Q2: What is the most important thing to look for in circular concrete formwork systems?

A2: Look for robust materials like ABS plastic or steel, adjustable elements for varying diameters, and easy disassembly features that minimize damage and allow for reuse. Also, consider compatibility with accessories and support systems, as well as safety features such as non-slip surfaces.

Q3: What are the factors to consider when purchasing circular formwork for concrete?

A3: The type of project, budget, desired finish, and frequency of use are important considerations. For projects with a high number of circular elements, it may be worthwhile to invest in more durable formwork systems, such as steel. Consider the complexity of the design and the desired finish. For projects with a focus on aesthetics, such as architectural features, formwork that allows for different textures and finishes may be necessary.

Q4: How can I maintain my circular concrete formwork to ensure longevity?

A4: After use, clean the formwork and store it in a dry place. Regularly inspect the formwork for any damage and make repairs as needed. Follow the manufacturer's instructions for disassembly and assembly to prevent damage. Avoid overloading the formwork beyond its specified capacity. Proper handling and storage can prevent dents and scratches.