(1210 products available)

The circular column formwork is a temporary structure to hold and shape concrete columns until the concrete hardens. It is designed specifically for circular or cylindrical columns. The formwork is built in the exact shape and size of the column, leaving the surface smooth and circular. Once the concrete is poured and set, the formwork is removed, leaving a solid concrete column that supports the building structure. The circular column formwork comes in different types, as explained below:

Traditional Circular Column Formwork

The traditional circular column formwork is a wood or metal framework that is built around the circular column. This formwork is designed to support the concrete until it dries and hardens. It can be adjusted to fit different column sizes. The formwork is stripped off the column once the concrete sets, leaving behind a circular concrete column. While this method works, it takes time to set up and requires skilled labor. It's also not as cost-effective as other options.

Aluminum Circular Column Formwork

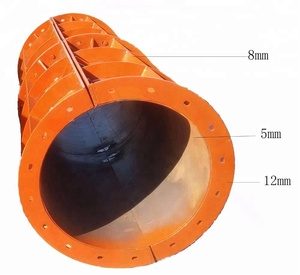

Aluminum circular column formwork is a type of formwork used for concrete columns that are circular in shape. The formwork is made from aluminum, a lightweight but strong metal. This formwork consists of two aluminum rings that fit around the column. The rings are connected with adjustable bolts and rubber spacers. The concrete is poured in between the rings. Once the concrete dries, the aluminum formwork is taken off the column. This allows for multiple uses of the formwork.

Modular Circular Column Formwork

Modular circular column formwork is a system of creating formwork for circular columns using pre-made modules. Each module is a small section of the formwork needed to make up the entire column. The modules are connected together to fit columns of different sizes. This system is quick and flexible. It takes less time to assemble and disassemble compared to traditional formwork. It's also adjustable because the formwork can be made from different materials like steel or aluminum.

Spiral Column Formwork

The spiral column formwork is specifically designed for concrete columns that are not just circular but also have a spiral shape. This formwork is adjustable and can be used for columns of different sizes and shapes.

Here are the main functions of column formwork:

Shaping Concrete Columns

Formwork molds concrete into the desired shape. This circular column formwork creates columns with the specified diameter and height.

Supporting Concrete Until It Cures

Column forms support the weight of the fresh concrete and any vertical loads during curing. This is called shoring.

Ensuring Column Alignment and Plumb

The forms keep the columns straight and vertical (plumb) so they are aligned with the building design. This is done using adjustable braces and tension wires.

Providing Surface Finish

The inner surface of the forms determines the finish of the cured concrete column. Smooth plastic or metal form liners give a polished finish, while wood grain or exposed aggregate options provide textured finishes.

Containing and Controlling the Concrete Pour

The forms keep the wet concrete contained and prevent it from spilling or slumping during pouring, which is important for taller columns. They also have access holes for workers and concrete pumps to use during filling.

Facilitating the Demolding Process

Once the concrete cures, the forms are removed. Circular column formwork is designed to allow easy demolding, such as with adjustable steel forms or single-use wood forms that can be pried off.

Key features of column formwork include:

Adjustability

Many formwork systems are adjustable. This allows columns of different sizes and shapes to be formed. For example, some circular forms can be made larger or smaller in diameter as needed.

Lightweight Materials

Modern formwork is often made from lightweight materials like aluminum or thin-walled steel. This makes it easier to handle and assemble on site.

Modular System

Column formwork is usually a modular system with interchangeable components. This allows for quick assembly and disassembly and forms different column sizes.

High Strength and Rigidity

The forms must be strong and rigid to support heavy concrete without deforming. This ensures straight walls and columns of the required strength.

Smooth Interior Surface

The interior surface of the forms is smooth to give the concrete column a nice finish that meets architectural requirements.

Ease of Assembly and Disassembly

Column formwork is designed for quick and easy assembly and disassembly by construction workers. This helps speed up the column construction process.

Circular column formwork is used in various construction scenarios where circular or columnar concrete elements are required. Here are some common usage scenarios:

Building Construction

Building construction project involves the use of circular column formwork to support and shape concrete columns in skyscrapers, office buildings, residential apartments, parking garages, and other types of structures. The formwork creates columns that provide structural stability and load-bearing capacity.

Bridges and Overpasses

Circular column formwork is used to construct piers and bridge columns in transportation infrastructure projects like bridges, viaducts, and rail overpasses. The circular columns provide stability and support for the deck and passing vehicles or trains.

Parking Garages

Circular column formwork is commonly used in the construction of parking garages, both above ground and in multi-story configurations. The columns support the parking levels and vehicles.

Tunnels and Underground Structures

Tunnel construction and underground structures like metro stations and sewage treatment plants may utilize circular column formwork to create support columns that withstand soil pressure and other forces.

Industrial Facilities

Factories, warehouses, power plants, and refineries may employ circular column formwork to construct large-diameter columns that can support heavy loads and machinery.

Waterfront and Marine Structures

Circular column formwork is used in the construction of marine structures such as docks, wharves, piers, and marine platforms. It is also useful in building submersible structures like caissons and underwater columns.

Highways and Infrastructure

Circular column formwork is used to construct support columns for overpasses, underpasses, traffic intersections, and other infrastructure elements in highway and transportation systems.

Wind Turbine Foundations

Circular column formwork can be used to create monopile foundations for wind turbines, especially in offshore wind farm installations.

Architectural Features

In some cases, circular columns are used as architectural elements to enhance the aesthetics of a building, both internally and externally. Formwork may be used to create decorative or exposed concrete columns.

When choosing the right formwork, it is important to consider several factors to ensure the project is successful.

Diameter and Height

The concrete column circular formwork comes in different diameters and heights. Therefore, it is important to know the required diameter and height to accommodate the concrete column design. Also, choose a diameter and height that will fit the structural engineer's recommendation.

Material

The material used to make circular column formwork affects performance and cost. For instance, plastic formwork is lightweight and reusable, making it economical for small projects. On the other hand, aluminum formwork is durable and offers better concrete finishes. It is important to select the material that meets the project's budget and structural requirements.

Load Capacity

The load capacity of a formwork system is vital. It's essential to check the manufacturer's specifications to ensure the formwork can handle concrete weight and any additional loads during pouring and curing. Consider the concrete volume and site conditions to determine the required load capacity.

Ease of Assembly and Disassembly

Choose formwork that can be easily assembled and disassembled to reduce labor costs and construction time. Consider the number of workers on site and their skill level when choosing a complex or simple formwork system.

Surface Finish

The surface finish of the formwork directly affects the concrete finish. Therefore, it is important to choose a formwork material that provides the desired concrete finish.

Reusability

One of the main key benefits of formwork is its reusability. Therefore, it is important to consider the number of times the formwork can be reused. This helps to determine the overall cost of the formwork.

Transportation and Storage

Consider the transportation and storage space available on site. For projects with limited storage space, it is advisable to select lightweight formwork systems that can be easily transported and stored.

Q1: What are the circular column formwork?

A1: This is a temporary structure that is used to shape and support concrete columns during construction. It is designed to be reused multiple times in different construction projects.

Q2: What is the purpose of formwork in construction?

A2: The purpose of formwork is to provide a mold for the concrete to take shape as it is poured. It supports the weight of the wet concrete and ensures the final column is the desired shape and size.

Q3: What are the types of column formworks?

A3: There are several types of column formworks, including metal (aluminum and steel), wood, plywood, plastic, and circular column formwork.

Q4: How to install circular column formworks?

A4: First, prepare the site and ensure all materials are ready. Then, assemble the column formwork off-site or in a safe location. Once assembled, lift and position it to the desired location using appropriate machinery. Secure the formwork to the ground and any nearby structures for stability. Pour the concrete and allow it to cure before disassembling the formwork.