All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(85158 products available)

Chipboard, also known as particleboard, is an engineered wood product that is widely used in construction and furniture-making. It's made from wood chips, sawmill shavings, or even reclaimed wood, which are then bonded together using a heat-activated adhesive under high pressure. Here are the common types of chipboard in construction:

Standard Particle Board

Typically called standard particle board, the most commonly used type is made up mainly of wood chips and sawdust, glued, and compressed into shape. It is widely used in furniture, cabinets, and flooring underlayment because it is cheap and easy to work with. It is not water-resistant and should not be used in areas where there is a lot of moisture, such as bathrooms and kitchens.

Moisture-Resistant Particle Board

The moisture-resistant particle board includes a resin that makes it more resistant to water and humidity. Green boards are typically found in construction and interior uses, such as kitchen cabinets and bathroom accessories. Even if it is more expensive than the standard particleboard, it is still cheaper than MDF and plywood.

High-Density Particle Board

The higher the density of the particle board, the heavier and more durable it is. It is made with smaller particles, which gives it an even surface and makes it very strong. This kind of chipboard is used in high-end furniture, decorative items, and acoustic panels.

Soundproofing Chipboard

Due to its density and structure, soundproofing chipboard is frequently used in construction for acoustic ceilings and partitions. Soundproof particleboard is often used in commercial buildings, theaters, and music studios.

Electronics Particle Board

Insulating chipboard is a very high-density particleboard used in the furniture industry. It is perfect for manufacturing information boards and notice boards because of its exceptional mechanical and insulating properties. The board is also widely used in the construction of acoustic panels because of its sound-insulating properties.

Laminated Chipboard

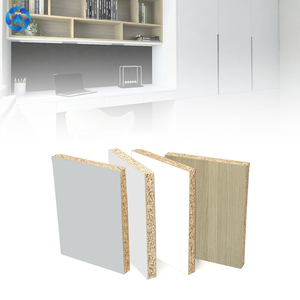

Laminated particle board consists of a layer of laminate or veneer on one or both sides of the board to enhance its aesthetic and functional properties. A laminated particle board, which is used in furniture, countertops, and doors, increases the board's scratch resistance and gives it a more appealing appearance.

Building Materials

Chipboard is a main material for buildings, and it is used for partitions, subfloors, and wall sheathing. It provides structural support and is usually less costly than solid wood or plywood.

Furniture Manufacturing

Because it is very inexpensive and easy to process, chipboard is a material widely used in the production of furniture. It is used to produce cabinet doors, shelves, and other pieces of furniture. When covered with veneer or laminate, it can closely resemble solid wood in appearance.

Retail Displays and Packaging

Chipboard is extensively used for cardboard boxes, shopping bags, and retail stand displays. Chipboard is suitable for packaging and marketing goods because it is robust yet lightweight.

Flooring

Chipboard can also be used in engineered wood flooring systems, including the exterior layer of some laminate flooring, because of its versatility and affordability.

Eco-Friendly

Chipboard is made from wood waste and byproducts, which makes it an environmentally friendly alternative to solid wood. Its production utilizes nearly every part of the tree, reducing waste in the forestry industry.

Cost-Effective

Chipboard is less expensive compared to plywood and MDF, making it a popular choice for budget-conscious construction and furniture projects. Its cost-effectiveness comes from the use of recycled wood materials.

Versatile Surface Finishing

The surface of chipboard can be easily laminated, veneered, or painted. This makes it very useful for producing furniture and interior designs. Chipboard can be designed for different aesthetic needs and applications.

Stability and Strength

Particleboard is less likely to warp or crack than solid wood because it is made of glued wood particles. Even though it is mostly hollow-core, it still maintains structural integrity and is heavyduty

Chipboards can be designed with different surface finishes and colors to increase their aesthetic appeal. Laminates, veneers, and paints can be used to make chipboard look more elegant and give it different textures. In addition, chipboards can also be designed in different thicknesses and densities to meet different functional needs, such as making furniture, making flooring, and using decorative items.

The boards can also be CNC-machined or routed for precise cuts, patterns, and designs in custom furniture or architectural applications.

Density and Thickness

Particleboards come in different thickness levels. Choose a thicker board for tasks that involve a lot of weight or need structural support, and a thinner one for lighter jobs. Higher density means more strength, which is ideal for making furniture and flooring.

Moisture Resistance

If the chipboard is meant to be used in a moist process like bathroom furniture or kitchen flooring, choose a moisture-resistant particle board. Standard particle boards are not suitable for highly humid areas, so choose HDF or MDF moisture-resistant particle boards.

Surface Finish

Consider what kind of finish you would like on the chipboard. Chipboard can be laminated with veneer, laminate, or other materials to achieve different looks and enhance its durability. Choose a finish that meets your aesthetic and functional needs.

Load-Bearing Capacity

Consider the weight or load that the chipboard will have to support. For shelves or flooring, higher load-bearing capability is required, so higher density or graded particle boards should be chosen.

Application

For different uses, different types of chipboards are suitable. Select the right kind of particleboard according to its preferred use, whether it is for building construction, making furniture, or doing some decorative work. For example, sound-insulating particle boards can be used in acoustic panels and interior displays.

Grade

Particleboards are rated based on their strength, density, and intended uses. Select the appropriate grade for the specific project, as furniture-grade boards feature smoother finishes and higher density than construction-grade ones.

A.

Because of its cheap price and ease of handling, chipboard is mainly used in the furniture industry, especially for cabinets, shelves, and inexpensive furniture. It is also widely used to make doors, flooring, and countertops. Chipboard is used as a base material for packaging, retail displays, and construction applications such as wall sheathing and underlayment.

A.

Because of its affordability, eco-friendliness, and ease of processing, chipboard is preferred in many industries. Because it is produced from wood waste, it is environmentally friendly. It is more affordable than plywood and solid wood because it can be remodeled into various products.

A.

Standard chipboard is unsuitable for outdoor use due to its susceptibility to moisture and humidity. However, moisture-resistant chipboard can be used for moderate outdoor applications, such as covered patios or deck furniture. It is better to use plywood or other materials for outdoor applications, as they offer better weather resistance.

A.

Chipboard is less expensive than plywood, mostly because it is made from small wood particles glued together, while plywood is made from thin layers or plies of wood veneer. While both have different uses, chipboard has more uses in furniture and flooring due to its density, acoustics, and surface finish. Plywood is stronger and more versatile than particle board, though, and is excellent for structural applications.

A.

Chipboard is highly recyclable. It is made from wood waste and byproducts, so it can be reused in making new engineered wood products. Recycling helps reduce the demand for new timber, making it an environmentally sustainable choice.

A.

Manufacturers first break down wood logs into small particles, such as chips, sawdust, and shavings. The particles are dried and mixed with a resin adhesive. They are then compressed into sheets and exposed to high pressure and temperature to cure the resin. This process gives the chipboard its strength and density. After curing, the boards are cut to size and finished for various uses.