All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2367 products available)

In the realm of industrial and commercial applications, china wedge gate valve serve a crucial role in regulating the flow of liquids through pipelines. These mechanisms operate by lifting a round or rectangular gate out of the fluid's path, allowing for a controlled flow. Known for their reliability and durability, china wedge gate valve are primarily used in systems where a straight-line flow of fluid and minimal restriction is desired. They are a staple in industries such as water treatment, oil and gas, and chemical processing, offering a robust solution for managing fluid dynamics within complex pipeline systems.

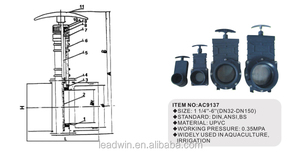

There are several types of china wedge gate valve , each designed to meet specific operational needs. The most common types include solid wedge, flexible wedge, and split wedge or parallel disk gate valves. Solid wedge china wedge gate valve are the most widely used due to their simplicity and strength, suitable for various applications. Flexible wedge valves feature a cut around the perimeter to improve seat alignment and reduce sticking, making them ideal for handling thermal binding. Split wedge or parallel disk gate valves consist of two solid pieces that align against the seats, providing a tight seal in high-pressure applications. Each type of china wedge gate valve offers distinct advantages, allowing for optimal performance in different environments.

The primary function of china wedge gate valve is to start or stop the flow of liquid. They operate by moving a gate up or down to open or close the passage, providing excellent shut-off capabilities. One of the key features of china wedge gate valve is their ability to provide a full bore flow, which means there’s no restriction in the flow path when the valve is fully open. This minimizes pressure loss and is crucial in applications where pressure drop needs to be kept to a minimum. Additionally, china wedge gate valve are bi-directional, meaning they can control flow in either direction, adding to their versatility in various industrial applications.

Constructed from a variety of materials to suit different operational environments, china wedge gate valve can be made from metals such as cast iron, ductile iron, carbon steel, and stainless steel. The choice of material impacts the valve’s durability, temperature, and pressure handling capabilities. For example, stainless steel china wedge gate valve offer excellent corrosion resistance and are ideal for aggressive chemical environments, while cast iron valves are cost-effective and suitable for non-corrosive applications. The construction of china wedge gate valve typically involves precision-engineered components to ensure reliable performance and longevity, even in demanding conditions.

Proper usage and maintenance of china wedge gate valve are essential for ensuring long-term functionality and reliability. It is important to operate these valves fully open or closed to prevent damage from flow-induced vibration. Regular maintenance involves checking for leaks, ensuring the gate moves smoothly, and inspecting the sealing surfaces for wear and tear. Lubrication of moving parts is also necessary to maintain operational efficiency. In systems where china wedge gate valve are used frequently, scheduled inspections and maintenance can prevent potential failures and extend the lifespan of the valve, safeguarding the integrity of the entire pipeline system.

Choosing the right china wedge gate valve involves understanding the specific requirements of your application. Considerations include the type of material, size, pressure rating, and the environment in which the valve will be used. For instance, stainless steel china wedge gate valve are suitable for corrosive environments, while cast iron options might be more cost-effective for non-corrosive applications. Understanding the flow characteristics and compatibility with other system components is crucial for ensuring optimal performance and longevity.

The size and pressure rating are also critical when selecting china wedge gate valve . The valve must be compatible with the pipeline's diameter and capable of withstanding the system's pressure. Too small a valve can cause bottlenecks, while an oversized valve may lead to unnecessary costs and inefficiencies. Pressure ratings help ensure that the valve can handle the operational demands without risk of failure, making it essential to match the valve specifications with system requirements.

When selecting china wedge gate valve for high-pressure applications, it is essential to consider the valve's pressure rating and material construction. Valves made from robust materials like carbon steel or stainless steel can withstand higher pressures. Additionally, the design, such as a parallel disk or split wedge, can offer better sealing capabilities under high pressure, ensuring reliability and safety.

china wedge gate valve differ from other valves primarily in their mechanism and application. Unlike ball or globe valves, gate valves provide a straight-line flow with minimal restriction, making them ideal for applications requiring full bore flow. Their design allows for excellent shut-off capabilities, but they are not typically used for throttling or flow modulation.

Yes, china wedge gate valve can be used in both liquid and gas applications. Their bi-directional design allows them to control flow efficiently in either direction, accommodating various mediums. However, it is crucial to ensure that the valve's material and design are compatible with the specific properties of the gas or liquid, such as temperature and corrosiveness.

Regular maintenance of china wedge gate valve includes checking for leaks, ensuring smooth gate movement, and inspecting sealing surfaces for wear. Lubrication of moving parts is necessary to maintain operational efficiency. Scheduled inspections can prevent potential failures, especially in systems where the valves are frequently used, thereby extending their lifespan and maintaining system integrity.

Environmental considerations for china wedge gate valve include selecting materials that resist corrosion and can handle specific environmental conditions, such as extreme temperatures or chemical exposure. Additionally, some valves are designed for reduced environmental impact by minimizing leakage and enabling efficient flow control, contributing to sustainable operational practices.