Introduction to Chamfering Mill

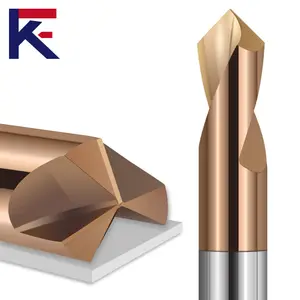

A chamfering mill is a specialized cutting tool designed to create beveled edges, or chamfers, on various materials. This unique milling tool is essential in the machining industry for finishing edges to improve both aesthetics and functionality. The chamfering mill operates efficiently in various machining operations, allowing for high precision and reduced risks of injury or material damage.

Types of Chamfering Mills

Chamfering mills come in several types, each designed to accommodate specific applications and material properties:

- Solid Carbide Chamfering Mills: These mills are made from solid carbide material, providing durability and superior cutting performance. They are ideal for high-speed machining of hard materials.

- Cobalt Chamfering Mills: Known for their heat resistance and strength, cobalt mills are suitable for high-temperature applications and can handle a variety of materials.

- Indexable Chamfering Mills: These tools utilize replaceable cutting inserts, which allow for cost-effective operations and versatility in chamfering different material types.

- HSS (High-Speed Steel) Chamfering Mills: These are more economical and widely used for moderate-speed operations on softer materials.

Function, Feature, and Design of Chamfering Mill

The function of a chamfering mill is to remove material at specific angles, helping create a smooth and polished edge. Key features and designs include:

- Precision Cutting: Chamfering mills are manufactured with precise angles and cutting edges, ensuring quality finishes without excessive material loss.

- Multiple Flutes: Many chamfering mills are designed with multiple flutes, allowing for efficient cutting action and increased chip evacuation.

- Variety in Cutting Angles: These mills can be available in various cutting angles, commonly ranging from 15° to 60°, suitable for different applications.

- Enhanced Chip Control: Chamfering mills are engineered to optimize chip flow, reducing the likelihood of chip jamming during operations.

Applications of Chamfering Mill

Chamfering mills find applications in diverse sectors due to their versatility and efficient performance. Some common uses include:

- Metalworking Industry: It is extensively used in metalworking to create precise angles on machined parts, enhancing their fit and functionality.

- Aerospace Manufacturing: In the aerospace sector, chamfering mills ensure precise tolerances and fitment for critical components.

- Automotive Engineering: Used for deburring and finishing edges of various automotive parts, ensuring safety and performance integrity.

- Woodworking: Chamfering mills are applied in woodworking to create visually appealing edge details while improving the longevity of the products.