All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2503 products available)

Chain conveyor components are integral to the material handling sector, facilitating the movement of goods across various industries. These systems are comprised of numerous interconnected parts, each playing a pivotal role in the conveyor's operation. The efficiency of a chain conveyor relies on the seamless interaction between its elements, ensuring a smooth and continuous flow of products.

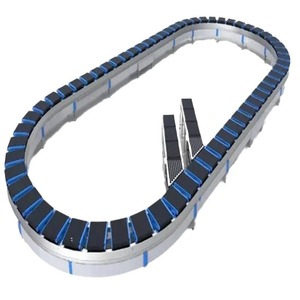

The versatility of chain conveyors is reflected in their various types, such as drag chain conveyors, roller chain conveyors, and modular chain conveyors. Each type serves distinct industries and applications, from heavy-duty material handling to delicate product transportation. For instance, bucket elevator chains are designed for vertical lifting of materials, while plastic chain conveyors are suitable for lightweight products and clean environments.

Conveyor chains are designed with durability and efficiency in mind. Materials range from low-mass alloys, commonly used for their strength-to-weight ratio, to robust steel or rope chains for heavy-duty applications. Features such as conveyor chain sprockets and chain driven conveyor rollers are engineered to minimize wear loss and extend the service life of the system. The construction of these components ensures a balance between tensile strength and flexibility, crucial for the diverse demands of industrial machinery.

Employing chain conveyor systems in material handling offers numerous advantages. Their simple yet effective design allows for an efficient transmission effect with minimal maintenance. The longevity of these systems is a testament to their low wear loss and the high-quality engineering of components like conveyor slat chains and flat top chains. Moreover, the adaptability of types of chain conveyors means they can be tailored to a wide range of operational needs, from light to heavy loads.

Innovation in the field of chain conveyors has led to the development of advanced systems like table top chain conveyors and overhead chain conveyors. These modern solutions are designed to meet the evolving needs of industries, offering enhanced flexibility and space efficiency. The integration of conveyor drive chains and drag chain conveyor parts into these systems exemplifies the progress in conveyor technology, aiming to provide more precise and controlled material handling processes.

Choosing the right components for a chain conveyor system is crucial for optimal performance. Factors such as load capacity, environmental conditions, and the nature of the materials to be transported should guide the selection process. Components like conveyor chains and sprockets and top chain conveyors must be matched with the specific requirements of the application to ensure reliability and efficiency.