All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(870 products available)

Carbon steel AISI 1522 comes in different forms. They include:

Sheets

AISI 1522 sheets are thin, flat pieces of steel. They are made by rolling or cutting. They are often used because of their balance between strength and flexibility. These sheets are common in automotive and appliance production. It’s worth noting that they can be easily welded, machined, and formed.

Plates

Plates are thicker than sheets. They provide structural support in construction and manufacturing. AISI 1522 plates are durable and resistant to deformation under heavy loads. They make ideal materials for building frameworks and components that require both strength and toughness.

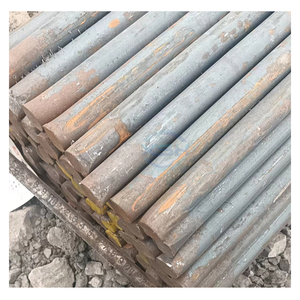

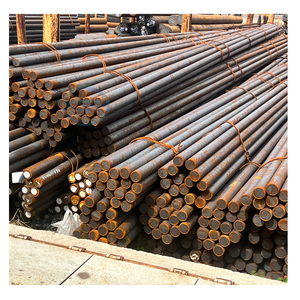

Bars

AISI 1522 carbon steel bars are commonly applied in construction and machinery. These rods are essential for reinforcement in structures. Additionally, they are used to manufacture components where high tensile strength is necessary. Further, their excellent wear properties make them suitable for high-impact and heavy-load applications.

Coils

Manufacturers produce AISI 1522 steel coils. They usually produce them by rolling the steel to the desired thickness. These coils are typical for applications that require long continuous lengths of steel. They are also useful in construction and automotive parts manufacturing.

Tubing

AISI 1522 steel tubing is ideal for applications such as structural and fluid transport systems. This is due to its strength and resistance to corrosion properties. The steel is commonly applied in automotive exhaust systems, pipelines, and mechanical structures. Its balance of flexibility and durability lends itself well to both engineering and industrial uses.

The carbon steel AISI 1522 consists of various features. They include:

Corrosion Resistant

The AISI 1522 comes with superior corrosion resistance compared to other carbon steels. This is due to the incorporation of chromium which forms a protective oxide layer. Users regard it as ideal for applications in environments prone to moisture and chemicals.

Toughness and Hardness

AISI 1522 strikes a balance between toughness and hardness. This makes it suitable for applications requiring both durability and resistance to deformation. The toughness ensures that the steel can absorb impacts without cracking. On the other hand hardness enables it to withstand wear and abrasion.

Formability and Weldability

The alloy composition of carbon steel AISI 1522 improves its formability. Users can easily machine and fabricate into various shapes and components. It makes it an ideal choice for industries that require complex designs. It also ensures that welding does not compromise its strength.

Versatility

Manufacturers use AISI 1522 in numerous industries. These include automotive, construction, and manufacturing. Its versatility enables it to cater for a wide range of uses. They include structural components, fasteners, and gear.

Heat Treatment

AISI 1522 responds well to heat treatment. It enhances its mechanical properties. Users can tailor the steel’s hardness and strength to meet specific application requirements. This makes it a flexible option for industries requiring customized solutions.

Carbon steel AISI 1522 has varying durability. They include:

Corrosion Resistance

Aisi 1522 carbon steel contains chromium. This enhances its corrosion resistance compared to typical carbon steels. It forms a protective oxide layer on the surface. This protects against rust in moisture-rich environments. It makes it ideal for outdoor and marine applications.

Toughness

The steel is tough and can absorb impacts without cracking or breaking. This toughness makes it ideal for heavy-duty applications. They include construction, machinery, and automotive components that are exposed to frequent impacts and stress.

Heat Treatment

AISI 1522 responds well to heat treatment. It allows users to enhance hardness and strength. Tailoring these properties makes carbon steel suitable for high-performance applications. They include cutting tools, dies, and high-stress machinery components.

Wear Resistance

The alloy’s hardness makes it resistant to wear and abrasion. It is useful in applications where frequent mechanical contact occurs. This includes machinery parts, tooling, and heavy wear surfaces.

Long-lasting and Cost-Effective

AISI 1522’s alloying elements improve its durability properties over standard carbon steels. While it may be slightly more expensive at initial purchase than other carbon steel types, its longevity in high-stress environments will often make it a more cost-effective option in the long run.

Carbon steel AISI 1522 has various applications. Here are some of them:

Machinery Components

AISI 1522 is typical for manufacturing components used in machinery. This is due to its combination of strength and corrosion resistance. Its properties enable the steel to withstand wear. Henceforth, it makes an ideal material for gears, shafts, and other machine parts that encounter heavy loads and friction. Further, it ensures longevity and durability in demanding industrial settings.

Automotive Parts

The steel is useful in the automotive industry. Manufacturers use it to produce chassis and suspension components. It also works for critical parts like drive shafts. These applications require both strength and flexibility under varying loads. The alloy’s ability to resist deformation contributes to the overall performance and safety of vehicles in rugged environments.

Construction Materials

Carbon steel AISI 1522 is typical for structural applications in construction. Builders use it for beams, columns, and reinforcements in commercial and residential buildings. Its toughness provides essential support and withstands loads without bending or warping. This makes it a go-to choice for maintaining structural integrity.

Fasteners and Hardware

Manufacturers make bolts, screws, and other fasteners from this steel. Its strength and corrosion resistance make it suitable for securing critical components in various industries. These industries include automotive, aerospace, and construction. Users use it in applications where reliable and durable fastening is essential.

Industrial Equipment

Carbon steel AISI 1522 is common in tools and equipment for industrial settings. Typically, users make it for tools that require high levels of wear resistance. These include cutting tools, dies, and molds. The ability to maintain sharp edges and forms under extended use distinguishes it in heavy-duty applications.

Selecting carbon steel AISI 1522 for customers involves considering several factors. Here are some of them:

Type

The steel is typically used for stamping and cold forming applications. It is due to its balance between strength and ease of machining. Supplier should stock it in a variety of forms to suit distinct uses. They include sheets, plates, and bars. Each buyer’s needs could be distinct and depend on the thickness. Suppliers use sheets and plates for the lightweight structures they fashion. On the other hand, they use bars for reinforcing and structural purposes.

Source

To minimize corrosion, AISI 1522 carbon steel usually comes with a small percentage of alloying elements like chromium and nickel. However, it is typically better than normal carbon steel in terms corrosion resistance. Suppliers should seek steel from established manufacturers. They often have a variety of treatments that could improve rust resistance, such as galvanization or coating.

Features

Customers ordering alloy steel may require different carbon steel shapes like steel bars and spikes. Before placing an order, a steel’s grade and mechanical properties must be confirmed. For instance, AISI 1522 is low-carbon steel with a tensile strength of roughly 55,000 psi and yield strength of around 48,000 psi, together with forming and stamping. However, depending on their application, customers might require various grades and strengths.

Brand

AISI 1522 alloy steel has several processes to enhance its durability. These include heat treating and work hardening. Buyers might also prefer brand options as certain manufacturers have stronger alloys than others. To minimize rusting, some brands might also have coatings or protective finishes.

Supplier reputation

Before purchasing steel, buyers consider the supplier’s reputation. They ask questions like how the steel was processed. More importantly, steel is suited to various applications. So, a supplier’s ability to advise on the most suitable forms and grades is essential.

Here are some frequently asked questions and answers about carbon steel AISI 1522:

Q1. What is the typical use of carbon steel AISI 1522?

A1. Carbon steel AISI 1522 is manufacture with flexibility in diverse purposes. For instance, it is common in the automotive industry for components such as gears and axles. It is also used for structural reinforcement. Besides, the material is common in machinery parts.

Q2. What form does carbon steel AISI 1522 come with?

A2. Carbon steel AISI 1522 is available in various forms. They include sheets, plates, bars, and coils. Moreover, it can be fabricated into components like fasteners, brackets, and machine parts. Besides, the material can be machined into complex shapes for distinct applications.

Q3. What are the advantages of carbon steel AISI 1522?

A3. Carbon steel AISI 1522 incorporates iron, carbon, and small alloying elements like chromium and nickel. Thus, making it more resistant to corrosion. Its machinability makes it easier to form into required shapes for distinct applications. Henceforth, its versatility allows usage in automotive, industrial, and construction applications.

Q4. What should customers consider when purchasing carbon steel AISI 1522?

A4. When buying carbon steel AISI 1522, customers consider quality and supplier reputation. They check the certifications to ensure they meet industry standards. They also consider compatibility with their manufacturing processes. Moreover, they assess the material’s mechanical properties to ensure it meets application requirements.

Q5. What can people do to preserve the quality of carbon steel AISI 1522?

A5. To preserve carbon steel AISI 1522, people understand its properties and use it properly. They use proper technique at they work to prevent contamination. They wipe the steel to keep it clean as contamination affects its properties. Further, they keep it in an optimal environment to enhance its workability.