All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(77448 products available)

Cap sealing machines have several types based on their application and operation.

Inner sealers

An inner cap sealer machine is under the cap itself. This machine applies pressure to the cap to secure the container and the product. The inner seals may be made of various materials, including foam, PVC, and others, and they are designed to provide a secure seal while also allowing for easy cap removal.

Manual capping machines

A manual bottle cap sealing machine requires an operator to manually place and secure the cap on the bottle. Manual capping is common for small-scale production or bottling at home. Operators may use their hands or other tools to press down and secure the cap. Unlike other types of sealing machines, manual capping machines will not seal the cap to create airtightness.

Trigger spray cap sealers

Spray Trigger Cap Sealers are sealing machines applied to trigger spray bottle caps. They help preserve the contents of the bottle, control product dispensing, and prevent leakage or contamination before purchase. These Cap Sealers may be made of shrink bands, breakable or non-breakable tamper-evident caps, or other sealing mechanisms. Using a Shrink Cap Sealers is common for bottles that require trigger spray caps, such as cleaning products, fragrances, and personal care items.

Automatic capping machines

An automatic capping machine (or automatic bottle capper) is a device used to seal containers with caps without manual intervention. These machines are typically used in high-production facilities to efficiently and consistently apply caps to bottles at high speeds. An automatic machine may use different capping methods (snap, torque, etc.) and feature varied capping head designs depending on the bottleneck and cap shape.

Outer cap sealers

Outer cap sealers, or outside sealers, are sealers applied around the outside of the neck of a bottle, under or around the cap. Outer sealers provide a visual indication of tampering and help keep the cap attached to the bottle, even in high tipping incidents.

Tamper-evident caps are common outer sealers, which require the customer to break the cap before accessing the product.

Heat shrink sleeves are plastic sleeves placed over the cap that, when heated, contract to form a seal around the cap. Heat shrink sleeves are commonly used on containers with multiple caps.

Induction cap sealers

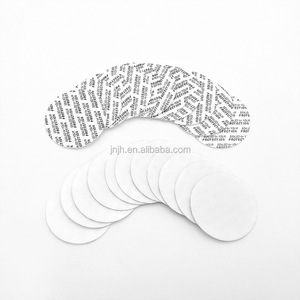

An induction cap sealer is a device used to apply an induction seal to the threaded cap of a container. Induction seals provide tamper evidence and help make a waterproof container/view. This type of cap sealer machine uses electromagnetic induction to create heat that melts the plastic lining of the cap, bonding it to the container.

Laboratory cap sealing machines

A laboratory cap sealing machine is a machine used to seal caps on laboratory bottles or containers. These containers are often used in scientific research, chemical storage, medical testing, or other laboratory applications. Cap sealing helps ensure that the cap is securely positioned and that the contents of the bottle are protected from contamination, evaporation, or chemical reactions. There are various types of cap sealings for the laboratory, including snap cap sealings, crimp cap sealings, and screw cap sealings.

A cap sealing machine is widely used in various industries for sealing bottles and jars. In the food and beverage industry, these machines are used to seal sauces, jam, juice, milk, beer, and other products, ensuring freshness and preventing contamination. Pharmaceutical companies use cap sealing machines to seal medicine bottles, ensuring drug integrity and safety. In the cosmetics industry, these machines are employed to seal cosmetic bottles, such as lotions, creams, and perfumes, to prevent leakage and maintain product quality.

Cap sealing machines are also widely used in the chemical industry for sealing bottles and jars containing chemicals, such as cleaners and paints. In the automotive industry, these machines can seal oil bottles and other automotive fluid containers. Furthermore, cap sealing machines are applicable in assembly lines for manual or automatic bottling, which requires sealing caps. They are also used in warehouses and distribution centers for cap inspection and re-sealing services.

Overall, cap sealing machines play a crucial role in various industries, ensuring product quality, safety, and convenience for consumers and producers.

When selecting a bottle cap sealing machine, several key factors need to be considered:

Sealing types

Various bottle cap sealing machines are available for different sealing requirements. For example, an induction cap sealer machine is used to provide plastic-lined bottle seals for products requiring tamper-proof seals. Another example is the pour spout capper which seals flip-top pour spout caps. Choosing the correct sealing machine type will ensure that the product is sealed properly.

Production rate

Consider the production rate the sealing machine can achieve. This should depend on the number of sealed bottles required per hour to meet production demands. Choose a machine that provides the necessary production capacity to avoid bottlenecks in the production line.

Cap type compatibility

Ensure the sealing machine is compatible with the specific type of cap being used. Test the machine to ensure it accurately fits and seals the cap without any issues before purchasing it.

Ease of operation and setup

Consider a machine that is easy to use and set up, as this will help reduce downtime during production. Choose an induction cap sealer that has quick-change cap setups and minimal operational requirements.

Durability and maintenance requirements

When choosing a bottle-sealing machine, consider the long-term costs of maintenance and repair. A durable and high-quality machine will have low maintenance requirements, which can help reduce overall production costs.

Q1: What are the benefits of using a cap sealing machine?

A1: Cap sealing machines provide several benefits. They enhance product security by providing a tamper-evident seal, keeping users safe. They also improve shelf life by preventing cap leakage, thus increasing sales. Furthermore, the machines ensure consistent sealing, raising a company's sealing standard.

Q2: What types of seals can cap sealing machines produce?

A2: Depending on the type of cap sealing machine used, various types of seals can be made. These include linerless seals, pressure-sensitive tape seals, adhesive gummed paper tape seals, and plain or printed tamper-evident abstract seals.

Q3: Can cap sealing machines be integrated into existing production lines?

A3: Sealing machines are usually fitted into production lines. Depending on the configuration of the present manufacturing line, the capacity of the machine, and the kinds of caps used, sealing machines of different types may be integrated. To accomplish a smooth production process, it is important to examine the compatibility with the current machines.

Q4: How do cap sealing machines handle different cap materials?

A4: Machines are designed to accommodate various cap materials, including plastic, metal, and biodegradable materials. They include interchangeable capping heads and chucks that can adjust to different cap shapes and sizes. The machines employ adjustable torque settings to apply the right sealing force without damaging the caps.