(7705 products available)

Building struts are structural components that help support, reinforce, and transfer loads in construction. They come in different types depending on the configuration, application, and load-bearing capacity. Here are the common types of building struts:

Steel Struts

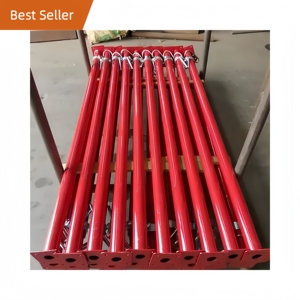

Steel struts are load-bearing components made of high-strength steel. They are used in construction projects that require load support and durability. Steel struts are designed to support and transfer heavy loads. They are commonly used in bridges, building frames, cranes, and industrial structures.

Aluminum Struts

These struts are lightweight and corrosion-resistant. They are made of aluminum alloy. Aluminum struts are primarily used in construction applications where weight reduction is important, such as in aircraft and automotive components. They are also used in temporary support structures and scaffolding.

Tension Struts

These are structural members that carry axial loads in a structure. They are specifically designed to support and resist loads. Tension struts are used in structures with cables or other members. They are commonly found in roof trusses, bridges, and tower structures.

Compression Struts

Compression struts are members that carry axial loads. They are specifically designed to resist compressive forces. Compression struts are used in building and aircraft structures. They are commonly used in internal bracing systems, such as in walls and fuselage of aircraft.

Diagonal Struts

These are structural members that are oriented at an angle between the vertical and horizontal members of a structure. They are specifically designed to provide stability and transfer loads. Diagonal struts are commonly used in truss systems, such as in bridges and roof structures.

Bahama Struts

They are struts used in the construction of window and door systems. They are specifically designed to provide support and stability. Bahamas struts are used in windows and doors in areas with high winds. They are commonly used in coastal areas and hurricane-prone regions.

Patio Struts

Patio struts are specifically designed to support and reinforce structures. They are commonly used in reinforced roof structures. They help prevent sagging and collapse. Patio struts are popular in residential construction. They provide an open feel and are made from different materials.

Building struts have various features and functions, including:

Load-bearing capacity

The building strut supports and carries loads efficiently. It transfers loads from beams, loads, and roof structures to vertical posts or columns. Struts distribute the weight or load to the vertical posts, ensuring the load is evenly distributed to the foundation. The even distribution of the load prevents structural failure.

Stability and Reinforcement

Building struts provide stability to the structure. It prevents lateral movement and ensures the structure remains stable during harsh weather conditions. The stability provided by the strut ensures the safety of the building and occupants. It also helps to prevent structural failure and collapse. The stability and reinforcement of building struts increase the lifespan of the structure.

Material and Durability

Building struts are made with materials like aluminum, wood, and steel. Some of the struts have a corrosion coating that prevents rust and increases durability. The materials used to construct building struts are strong, which ensures they can carry or support more loads. The durability of building struts reduces maintenance costs and increases the lifespan.

Versatility

Building struts are used in different industries and applications, such as construction, automotive, aerospace, and engineering industries. The versatility of building struts makes them popular among engineers and builders. It enables them to design and construct structures of different sizes and shapes.

Design and customization

Building struts come in different designs, such as tubular, L-shaped, and I-beam. The different designs allow builders and engineers to choose the right strut for a particular function. Some building struts are customized to meet specific structural requirements. The construction of building struts is engineered to ensure efficiency and effectiveness.

Ease of Installation

Building struts are easy to install because of their lightweight. The struts are designed for different structures, making them easy to fit and install. Some building struts have installation accessories that help to install them efficiently.

Building struts are essential in the construction industry, providing support and stability to structures. Here are some common usage scenarios:

Support beams

Struts are used as support beams in construction, providing structural support to horizontal loads. They are used in support load-bearing walls, roof trusses, and other structural elements. Building struts help distribute weight evenly to the foundation, ensuring the stability of the structure. Support beams are made of strong materials such as wood, steel, or aluminum.

Bridges

Struts are used in bridges to provide structural support and stability. They are used in the deck, trusses, and other structural elements of the bridge. Building struts help distribute weight evenly to the piers and abutments, ensuring the stability of the bridge. Struts are usually aligned diagonally in the bridge superstructure to transmit loads to the supports.

Buildings and skyscrapers

In high-rise buildings and skyscrapers, struts are used to support vertical loads and resist lateral forces. They are used in the core, columns, and other structural elements. Building struts help distribute weight to the foundation, ensuring the stability of the building. Struts are also used in wind-bracing systems to counter the effects of wind forces on tall buildings.

Aircraft

Building struts are used in aircraft to support the wings, especially in biplanes and some light aircraft. They provide stability and rigidity to the wing structure. Struts are also used to maintain the distance between the wings and support the landing gear in some aircraft designs.

Telecommunication towers

Struts are used in telecommunication towers to provide stability and support. They are used in the vertical sections of the tower, ensuring the tower can withstand wind and other lateral forces. Building struts are usually used in multiple sections and help transmit loads to the base, ensuring the tower remains stable and secure.

Frame of bicycles

Struts are used to support the frame components of a bicycle, especially mountain bikes and other rough terrain bicycles. They provide support and stability when cycling on rough terrain.

When choosing a building strut for any construction, there are many factors to consider. In this section, we will discuss how to select the ideal struts for a construction project.

The first thing to consider is the load capacity. Struts are used to support loads and reduce weight. Therefore, it is essential to determine the load capacity and choose a strut that can support it. Consider the weight of the roof or any load that will be placed on the strut. Choose a strut that is durable and galvanized to prevent rust.

The material of the strut is another critical factor to consider. Struts are made with different materials like aluminum, galvanized steel struts, and stainless steel. Aluminum is lightweight but less durable than galvanized steel. It is essential to consider the environmental conditions to choose the best material for the strut. Stainless steel or galvanized steel is ideal for a coastal region, while aluminum will be perfect for light-duty applications.

The length and size of the strut also matter. It is essential to choose the right size strut to provide the necessary support. Larger struts will support more loads, while smaller ones are ideal for light loads. The strut thickness also matters because a thicker strut will support more weight than a thinner one.

When choosing a strut, it is important to consider the type of connection. The connection is how the strut will be attached to the building. Welded connections are more robust and provide a permanent attachment, while bolted connections are easier to install and remove.

Another thing to consider is the cost of the strut. It is important to choose a strut that is within budget but also offers the necessary support for the construction project. Remember that cheaper options may not be the best, so balance cost and quality.

Finally, it is important to consult with a structural engineer or construction professional when choosing a building strut. They will provide expert advice and ensure that the right strut is chosen for the building.

Q1: How are struts different from traditional beams in construction?

A1: Unlike beams that horizontally transfer loads to vertical supports, struts diagonal or vertical bracing provide direct load support to compressing or resisting columns or walls. The angled positioning of struts gives an rigidity to the overall framework, allowing it to carry additional weight without collapsing. While beams require more supports across a span, struts efficiently transfer load forces through triangulation, making for a steadier, reinforced construction.

Q2: What are the most common materials used for building struts?

A2: Most construction struts are made of durable steel, aluminum, or reinforced wood. Steel and aluminum provide lightweight strength, while the wood offers cost-effectiveness when reinforced. The material choice depends on the strength requirements and load capacity needed.

Q3: How can builders determine the length and thickness of a strut?

A3: Engineers determine the thickness and length of struts based on the load-bearing capacity required and the distance between supports. Longer spans or heavier loads require thicker, more closely positioned struts. Calculating the load forces helps determine the appropriate strut dimensions for stability.

Q4: What maintenance do building struts require?

A4: Struts need regular inspections for signs of wear, splitting, corrosion, or structural weakening. Any issues should be promptly repaired to maintain integrity. For metal struts, periodic repainting may be needed to prevent rust. Keeping an eye on load limits and making sure they aren’t exceeded also helps maintain the struts over time.

Q5: What role do building struts play in supporting roofs and ceilings?

A5: Struts provide angled support that transfers the downward load of roofs or ceilings to vertical walls or columns. They help distribute the weight across a triangulated framework, allowing for more open interior spaces without as many vertical supports. This load distribution prevents roof sagging over time.