(1062 products available)

The world of plastics is vast and diverse, with various materials serving different purposes across numerous industries. Among these, best service expanded polystyrene pre expander holds a significant place, particularly in the packaging and construction sectors. Known for its lightweight and durable properties, best service expanded polystyrene pre expander is a type of expanded polystyrene that offers exceptional insulation and shock absorption capabilities. This material is not only cost-effective but also versatile, making it a popular choice for both industrial and consumer applications. As the demand for sustainable and efficient materials grows, best service expanded polystyrene pre expander continues to evolve, with innovations aimed at enhancing its performance and environmental impact.

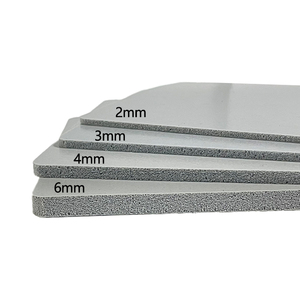

There are several types of best service expanded polystyrene pre expander available in the market, each designed to meet specific requirements. The most common types include standard EPS, high-density EPS, and fire-retardant EPS. Standard EPS is widely used for packaging and insulation due to its excellent thermal properties and lightweight nature. High-density EPS offers superior strength and is often utilized in construction applications, such as in structural insulated panels and geofoam. Fire-retardant EPS is specially treated to resist ignition and is used in settings where fire safety is a priority. Each type of best service expanded polystyrene pre expander is engineered to provide optimal performance in its respective application, ensuring safety and efficiency.

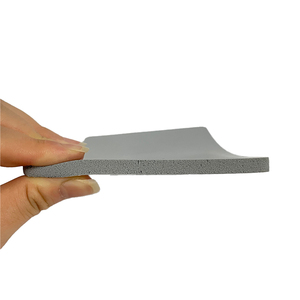

best service expanded polystyrene pre expander is renowned for its multifunctional capabilities, making it an indispensable material in various industries. Its primary function is insulation, where it helps maintain temperature stability in buildings and packaging. The lightweight nature of best service expanded polystyrene pre expander also makes it ideal for cushioning and protecting products during transportation. Additionally, it boasts excellent moisture resistance, which prevents damage from humidity and water exposure. The versatility of best service expanded polystyrene pre expander extends to its use in creative applications, such as in theater sets and art installations, where its ease of shaping and painting is highly valued. Its combination of durability and flexibility ensures that best service expanded polystyrene pre expander meets the diverse needs of its users.

The production of best service expanded polystyrene pre expander involves the polymerization of styrene, resulting in a rigid foam with a closed-cell structure. This structure is responsible for the material's excellent thermal insulation properties and its ability to withstand significant impact without deformation. Additives such as flame retardants, colorants, and stabilizers may be incorporated to enhance specific properties of best service expanded polystyrene pre expander . For example, flame retardants are added to improve fire resistance, while colorants can be used for branding or aesthetic purposes. The choice of materials and additives plays a crucial role in determining the performance characteristics of best service expanded polystyrene pre expander , enabling manufacturers to tailor the material to suit various applications and industry standards.

To utilize best service expanded polystyrene pre expander effectively, it is essential to choose the appropriate type and density based on the intended application. In construction, selecting the right density ensures optimal structural support and insulation performance. For packaging, the size and shape of best service expanded polystyrene pre expander should be tailored to provide maximum protection for the product. It is also important to consider environmental factors, such as exposure to sunlight and humidity, which may affect the material's longevity. Proper installation and handling techniques are crucial to maintaining the integrity of best service expanded polystyrene pre expander , whether it's used in building insulation or product packaging. Additionally, recycling and disposal practices should be followed to minimize environmental impact, as best service expanded polystyrene pre expander is not biodegradable. By understanding and applying these principles, users can maximize the benefits of best service expanded polystyrene pre expander while contributing to sustainability efforts.

When selecting best service expanded polystyrene pre expander , it is crucial to consider the specific requirements of your application. One of the primary factors to evaluate is the density of the material. Different densities provide varying levels of strength and insulation, making them suitable for different uses. For example, high-density best service expanded polystyrene pre expander is often preferred in construction applications for its structural integrity, while standard density is ideal for packaging purposes due to its lightweight nature. Understanding the demands of your project will guide you in choosing the most appropriate type of best service expanded polystyrene pre expander .

Another important consideration is the environmental impact of the chosen best service expanded polystyrene pre expander . As sustainability becomes a growing concern, selecting materials that are recyclable or made with eco-friendly additives can significantly reduce the environmental footprint. Some manufacturers offer best service expanded polystyrene pre expander options that incorporate recycled content or are designed for easier recycling. Evaluating the environmental certifications and the recyclability of the material is essential for making an informed decision that aligns with sustainability goals.

The size and shape of best service expanded polystyrene pre expander are also important factors to consider. Depending on the application, you may require specific dimensions or features such as pre-cut shapes or custom molds to fit your project needs. For packaging, the shape and size of best service expanded polystyrene pre expander can affect the protection it offers to the contents. In construction, the dimensions can influence the ease of installation and the overall efficiency of the insulation. Customization options are available to tailor best service expanded polystyrene pre expander to meet specific requirements.

Additionally, cost considerations play a significant role in the selection of best service expanded polystyrene pre expander . While it is important to choose a product that meets performance requirements, budget constraints must also be taken into account. Balancing quality and cost-effectiveness is key to achieving the desired outcome without overspending. Consulting with suppliers about bulk purchase options and potential discounts can help manage costs while ensuring that the chosen best service expanded polystyrene pre expander meets all necessary specifications.

The density of best service expanded polystyrene pre expander affects its strength, insulation properties, and cost. Higher density provides greater durability and structural support, making it ideal for construction uses. Lower density is lighter and more cost-effective, suitable for applications like packaging. Consider the specific demands of your project to determine the appropriate density.

Ensuring sustainability involves selecting best service expanded polystyrene pre expander with recyclable properties or those made from recycled materials. Look for certifications that verify the environmental friendliness of the product. Additionally, consider the end-of-life options for the material, such as recycling programs or biodegradable alternatives.

Yes, best service expanded polystyrene pre expander can be customized in terms of size, shape, and density to suit different applications. Many manufacturers offer custom cutting and molding services to meet specific project requirements. This flexibility allows for tailored solutions that enhance performance and efficiency.

Fire-retardant best service expanded polystyrene pre expander is commonly used in applications where fire safety is a priority, such as in building insulation and packaging for flammable products. Its ability to resist ignition adds an extra layer of protection in environments with heightened fire risk, contributing to overall safety standards.

Cost is a significant factor in selecting best service expanded polystyrene pre expander . While higher quality or specialized types may come at a premium, it's important to balance the benefits with budget constraints. Exploring bulk purchase options and negotiating with suppliers can help manage costs while ensuring the material meets all necessary specifications.