Bentonite Rheological Additive: A Comprehensive Overview

Bentonite rheological additives play a crucial role in various industries by enhancing the viscosity and stability of products. These natural clays are derived from volcanic ash and have unique properties that make them indispensable in manufacturing processes. Whether used in paint, coatings, adhesives, or drilling fluids, bentonite additives ensure that formulations maintain optimal performance under diverse conditions.

Types of Bentonite Rheological Additives

There are several types of bentonite rheological additives, each designed to meet specific needs within different applications:

- Sodium Bentonite: Known for its high swelling capacity, sodium bentonite is often used in drilling fluids and as a binder in foundry applications.

- Calcium Bentonite: This type is commonly used in food and pharmaceutical applications due to its natural purity and non-toxicity. It also serves as an effective decolorizing agent.

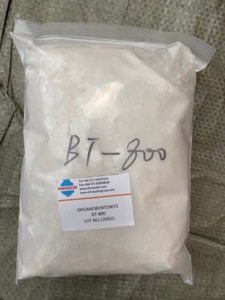

- Modified Bentonite: Chemically treated to enhance performance, modified bentonite additives offer superior dispersion and thicker consistency in products like paints and coatings.

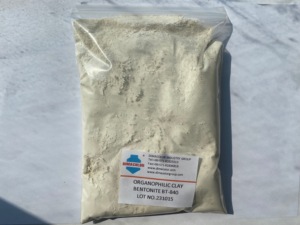

- Organophilic Bentonite: Tailored for use in oil-based systems, these additives demonstrate unique compatibility with non-aqueous mediums, enhancing stability and viscosity control.

Applications of Bentonite Rheological Additive

Bentonite rheological additives find applications across diverse sectors, enhancing quality and performance in:

- Construction Industry: Used in cement and mortar formulations, bentonite improves workability and enhances the durability of constructions.

- Paints and Coatings: These additives help achieve optimal viscosity and stability, ensuring uniform application and finish while preventing sedimentation.

- Pharmaceuticals: In the pharmaceutical industry, bentonite serves as a crucial excipient in various formulations, aiding in controlled release and suspension.

- Oil and Gas: Used in drilling fluids, bentonite rheological additives provide essential functionalities like lubrication, cooling, and the prevention of collapse in boreholes.

Features and Advantages of Bentonite Rheological Additive

When selecting bentonite rheological additives, it’s essential to understand their key features and advantages, which include:

- Thixotropic Properties: The ability to alter viscosity under shear stress makes bentonite invaluable for maintaining product stability.

- Natural Composition: As a natural clay, bentonite is environmentally friendly and safe, distinguishing it from synthetic additives.

- Exceptional Swelling Ability: This property allows bentonite to form gels, useful in a variety of thickening applications.

- Cost-Effectiveness: Bentonite additives offer a high-performance solution at a relatively lower cost, making them accessible for large-scale manufacturing.

- Compatibility: Bentonite can be blended effectively with various polymers and resins, ensuring versatility across multiple formulations.

In conclusion, bentonite rheological additives are integral to the manufacturing sector, providing essential characteristics that enhance product performance. Understanding the different types, applications, and unique advantages of these additives can ensure the optimal selection for your specific needs.