(41537 products available)

A batch label machine is used to apply labels to products in batches instead of individually. This machine is vital for industries that require labeling in bulk for efficiency. Here are a few types of batch label machines:

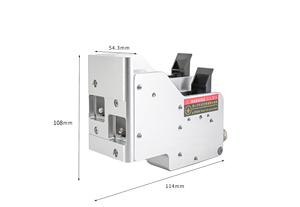

Label Dispensing Machine

This machine dispenses labels at a predetermined quantity. It works independently of other machines. The operator places the product in the machine. Once the machine batches the amount, it is ready for labeling.

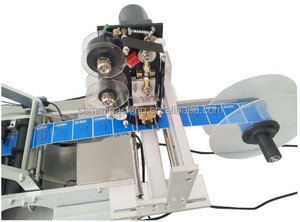

Label Application Machine

The label application machine is the most common batch labeling machine. It applies the label to a product in a set of specified quantities. The unit of product is set, and the machine applies labels to those units. It may involve changing label batches and adjusting to different products.

Label Coding Machine

Unlike the label application machine, the coding machine enters information onto a label in a set quantity. This may require changing the coding for different words, numbers, or phrases. Once the information is entered, the machine can produce that quantity of labeled products.

Label Printing Machine

With digital technology, the printing machine has transformed how products are labeled. This machine can produce a set number of labels with the required information and graphics. It is the most efficient machine when producing custom labels in bulk.

Semi-Automatic Labeling Machines

This machine uses a manual system to feed products into the labeling zones. The products are aligned, and the label is applied within the designated zones.

Batch Labeling and Coding Machine

These machines simultaneously label and code products with the desired information. They are used widely in the food, beverage, and pharmaceutical industries.

Continuous Labeling Machines

The machine applies labels to products that are fed continuously through the machine instead of in batches. It is an efficient system when products are manufactured and produced in large quantities. The machine is equipped with sensors to locate the proper positioning to apply the label precisely.

The key specifications to consider when buying a batch label printing machine are the printing technology, label orientation, print width, resolution, and control system.

Because these machines go through the stress of handling many products at once, regular maintenance is essential to ensure they work well. The most important maintenance step is to regularly clean the machine. This is because product residue, dust, and label debris can quickly build up on the machine, especially on its rollers and adhesive parts, affecting its stickiness and label accuracy.

Using a dry cloth or air compressor, clean the feeder roll, delivery roll, and any other parts of the machine. While conducting targeted cleaning on specific parts of the batch label printing machine, use isopropyl alcohol or any other cleaning agent to remove stubborn residue. Regularly cleaning the machine will improve its label application precision and accuracy.

The application of the batch label machine is so widespread that it is hard to pinpoint a single industry where this machine is exclusive to. As previously stated, all industries that require products to be labeled for various purposes make use of this machine to aid in this task. However, to highlight some of the specific uses of this machine, here are some industry examples:

Food industry

In this industry, batch labeling machines are used to label various food items ranging from canned products, bottled products, packaged products, and bakery products, to name a few. These machines make it easy to comply with FDA requirements.

Pharmaceuticals

This machine makes it easy to comply with Pharma labeling requirements. In this industry, batch labeling machines are used to label bottles, boxes, vials, and blisters, to name a few.

Cosmetics

Labeling is done on bottles, jars, prominently used on the packaging of beauty products, and boxes, to name a few. With these machines, frequently used product labeling can be done easily and quickly.

Apparel

In this industry, batch labeling machines are used to label garment tags, care labels, and brand labels, to name a few. The labels help identify the brand, provide product information, and promote brand recognition.

Logistics and Transportation

In this industry, batch labeling machines are used to print and apply address labels, shipping labels, tracking labels, and barcodes.

Construction

In this industry, batch labeling machines are used to label pipe components, electrical wiring, and equipment, to name a few.

Electronics

In this industry, batch labeling machines are used to label product packaging, warranty stickers, and instructional labels, to name a few.

When purchasing batch labeling machines in bulk for business needs, it is important to consider a few key features before placing wholesale orders.

Labeling volume and speed

When purchasing in bulk, it is essential to think about the volume of labels that will be required and how quickly they need to be applied. Batch label machines come in a variety of speeds and volumes, so select one that can handle the necessary capacity while also meeting the anticipated production rate.

Flexible labeling

With batch production, it's critical to be able to label various products or containers without difficulty. Look for a machine that has adjustable settings or interchangeable components so it can easily handle other shapes and sizes. It may also help save long-term costs if it can handle a range of labeling materials, such as different label sizes and types including stickers, tags, and tape.

Durability and maintenance

When buying in bulk, select a machine that is sturdy so it can withstand continuous use over time. Look for one built with high-quality parts and materials. It's also important to consider the machine's maintenance requirements and warranty coverage. Choose a model that has easy-to-replace parts and straightforward maintenance procedures, along with a comprehensive warranty.

Operator training

Since multiple operators may need to use the machine over its lifetime, it's essential to select a model with user-friendly controls and clear instructions. Machines that come equipped with training manuals or video resources may help reduce operational errors and ensure the labeler is used to its full potential.

Automation system

As batch size increases, automation becomes more important to improve efficiency and reduce labor costs. Consider the level of automation required based on your production scale. While fully automated machines may have a higher upfront cost, they could be a more economical choice at higher volumes.

Q1. What is the difference between batch labelling and single-labeling in machines?

A1. In the process of labelling, batch labelling refers to a labelling method in which items are labelled in batches rather than individually. This is typically used in situations where identical labels are applied to multiple items. On the other hand, with the use of a label machine maker, one could apply labels to products individually. In some cases, batch labelling may be more efficient than applying labels to products one at a time.

Q2. Are batch label machines automatic or manual?

A2. Depending on the sort of machine and its construction, the batch label machine may be automatic or manual. In most cases, it has a combination of both.

Q3. Can batch label machines work with different label shapes and sizes?

A3. Yes. The machine can work with various label shapes and sizes as long as the labels are in the batches required to go through the machine at once.

Q4. Can batch label machines handle products of different shapes and sizes?

A4. Yes, in most cases, the machine can handle products of various shapes and sizes. Depending on the model, this may be true for some label machines but not for others. It is essential to check the specifications of the label machine to find out if it can handle different shapes and sizes of items.