All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(29516 products available)

A balancing machine is used to measure and correct the imbalance of rotatable parts. Balancing machines come in a variety of configurations, each suited for a particular application. The following are some of the most common types of balancing machines:

Before buying any balancing machine, it’s essential to understand its specifications. Here are some common specifications to expect.

Load capacity

Balancing machines have different load capacities depending on the type. For example, the wheel balancing machine can handle weights of up to 150 kg or more. The maximum load capacity is 300 kg or more. On the other hand, the rotor balancing machine can balance rotors with weights of up to 500 kg or more.

Speed of operation

The speed of operation varies depending on the type of balancing machine. For example, a static balancing machine has a static speed of operation. On the other hand, a dynamic balancing machine has a high speed of operation.

Accuracy

Accuracy is a crucial specification for balancing machines. For instance, the wheel balancing machine has an accuracy level of up to 1 gram. On the other hand, the rotor balancing machine has an accuracy level of up to 0.5 grams or less.

Measurement range

The measurement range is the minimum and maximum unbalance that the balancing machine can measure. For example, the measurement range of a wheel balancing machine is between 5 and 150 grams. On the other hand, the measurement range of a rotor balancing machine is between 0.1 and 10 grams.

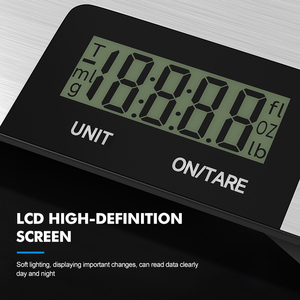

Display

Most balancing machines have displays to show measurements and results. The displays differ in size, type, and resolution. For example, some machines have an LCD display, while others have an LED display.

Calibration

Balancing machines require regular calibration to maintain accuracy. Calibration specifications include calibration weights and procedures. For example, some machines come with calibration weights, while others don't. The calibration procedure involves following the manufacturer's instructions.

Power supply

Balancing machines require different power supply specifications, such as voltage and frequency. For example, some machines operate on a power supply of 220V, while others operate on 110V.

Balancing machines are complicated devices. Therefore, they require regular maintenance to operate effectively and efficiently. Here are some of the maintenance requirements.

Regular cleaning

Cleaning the balancing machine regularly is essential to remove dust, debris, and dirt. A clean machine ensures accuracy and precision. Use a soft cloth and mild cleaning solution to clean the machine. A hard cloth can scratch the machine.

Check for wear and tear

Inspect the machine for worn-out or damaged parts. Replace any damaged parts immediately. This helps to prevent inaccuracies and precision loss.

Lubrication

Lubricate the moving parts of the balancing machine regularly. This reduces friction and wear and tear, increasing the lifespan of the machine. Use the recommended lubricant by the manufacturer.

Calibration

Regular calibration is essential to maintain the accuracy of the balancing machine. Follow the manufacturer's instructions for the calibration process.

Use the machine correctly

Always use the machine according to the manufacturer's instructions. Avoid overloading or using the machine for unintended purposes.

Store the machine properly

When not in use, always store the balancing machine in a dry and clean place away from direct sunlight and extreme temperatures.

With so many options in the market, it can be quite difficult to choose the right balancing machine for one's business. Here are some tips that can help retailers and wholesalers source the right equipment:

Consider the type of the rotor

Different rotors require different balancing techniques. This is because they come with different designs and operating principles. For instance, a helicopter rotor is balanced by adjusting the pitch angle of the blades, while a jet engine rotor is balanced by adding weights to the blades. Therefore, it is important to consider the type of rotor before choosing a balancing technique.

Check the balancing technique

There are several balancing techniques available, each with its own advantages and disadvantages. For example, static balancing is a simple and cost-effective technique, but it may not be suitable for high-speed rotors. Dynamic balancing, on the other hand, is a more sophisticated technique that can balance rotors at high speeds.

Evaluate the features

Different balancing machines come with different features. Some of the common features include vibration measurement, analysis software, and automatic correction. Buyers should choose a machine that has the features that meet their needs.

Consider the capacity

Buyers should choose a balancing machine that can balance rotors of different sizes and weights. It is important to consider the maximum and minimum rotor diameter and weight before purchasing a balancing machine.

Consider the budget

Buyers should have a budget for the balancing machine. The cost of the machine will be determined by its features, capacity, and the technology used. In most cases, static balancing machines are cheaper compared to dynamic machines.

Ease of use

Buyers should choose a balancing machine that is easy to operate. Machines that are complex require skilled personnel to operate, which can increase the operation cost. Apart from being easy to operate, the balancing machine should be easy to install and maintain.

When it comes to DIY and replace balancing machines, there are some necessary steps that need to be followed. Firstly, it is important to know that DIY activities related to balancing machines are generally limited to basic maintenance and troubleshooting. To replace a balancing machine, consult with the manufacturer or a qualified service provider for proper installation and calibration. Here's the guide to DIY:

Maintenance checks

1. Regularly inspect the machine for any signs of wear or damage. 2. Keep all components clean and free from dust and debris. 3. Ensure proper lubrication of moving parts as recommended by the manufacturer.

Leveling and alignment

1. Check that the balancing machine is level and properly aligned. 2. Adjust the feet or leveling pads as necessary to achieve stability. 3. Verify that measurement and adjustment components are correctly aligned.

Load capacity

1. Ensure that the balanced samples do not exceed the machine's specified load capacity. 2. Distribute the load evenly on the support structures. 3. Use appropriate fixtures and attachments for different types of samples.

Measurement accuracy

1. Periodically check and calibrate measurement instruments according to the manufacturer's instructions. 2. Use certified calibration weights to verify the accuracy of the measuring system. 3. Ensure that environmental conditions (temperature, humidity, etc.) are within the limits specified by the manufacturer.

Software and firmware updates

1. Check if there are any available updates for the machine's software and firmware. 2. Download and install updates according to the manufacturer's instructions. 3. Back up important settings and data before performing updates.

Safety precautions

1. Always follow safety instructions in the user manual. 2. Use personal protective equipment (PPE) when necessary, such as gloves, safety glasses, and hearing protection. 3. Be cautious when handling heavy loads and moving parts of the machine.

Q1: How often should a wheel-balancing machine be calibrated?

A1: The frequency of calibration depends on the usage level of the machine. For heavy usage, like in busy workshops, calibration should be done weekly. In workshops with moderate use, monthly calibration is enough. Always follow the manufacturer's guidelines.

Q2: Can a wheel balancing machine perform dynamic balancing?

A2: Yes, especially the advanced models. A wheel balancing machine can analyze the wheel's performance while in motion, identifying imbalances that static balancing alone might miss.

Q3: Is it necessary to balance new tires?

A3: Yes, it's crucial. Even new tires can have slight imbalances from the manufacturing process. Balancing ensures a smooth ride and prevents potential vehicle damage.

Q4: What are the signs of an unbalanced wheel?

A4: Common signs include vibrations felt in the steering wheel, uneven tire wear, and a noise that isn't typical when driving. In more severe cases, the vehicle might pull to one side.

Q5: How long does the wheel balancing process take?

A5: The actual balancing process takes about 15 to 30 minutes, depending on the machine's efficiency and the technician's expertise. Other factors, like removing and re-mounting the tires, can extend the overall time.