All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(3500 products available)

Forged car wheel hubs are used in different types of vehicles. They are categorized into different types based on the vehicle's make and model. Some common types of automobile wheel hub forgings include:

1. Single Wheel Hub

This type of wheel hub has one wheel hub on either side of the vehicle. Most cars and light trucks use this type of wheel hub. It is less costly and requires less maintenance. However, it wears out fast and is not suitable for heavy loads or off-road use.

2. Double Wheel Hub

The double wheel hub has two wheel hubs on either side of the vehicle. It is mostly used in heavy-duty trucks and some SUVs. The double wheel hub provides more stability and strength. It also has better load-bearing capacity. However, it is costly and requires more maintenance.

3. Flange Wheel Hub

The flange wheel hub has a flange at the end of the shaft. The flange has holes that allow attachment to the wheel. This type of wheel hub is used in sports cars and racing vehicles where quick wheel changes are required.

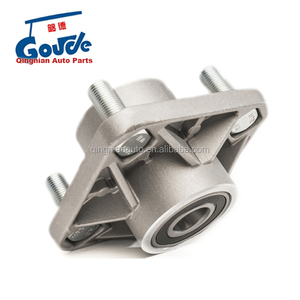

4. Stud Wheel Hub

The stud wheel hub has several threaded studs that protrude from the hub. The wheel is attached to the vehicle by bolting it to the studs. This type of wheel hub is commonly used in trucks and buses where high torque is required during wheel installation.

5. Center Locking Wheel Hub

The center locking wheel hub uses a single large nut in the center of the wheel to attach the wheel to the vehicle. This type of wheel hub is mostly used in off-road vehicles and racing cars. It allows for quick wheel changes and reduces unsprung weight.

6. Bearing Wheel hub

The bearing wheel hub combines the wheel hub and the wheel bearing into one unit. This type of wheel hub is commonly used in modern vehicles. It reduces maintenance needs and improves accuracy.

Specifications of automobile wheel hub forgings vary based on design, vehicle requirements, and manufacturer standards. Here are some general specifications:

Material

Automobile wheel hub forgings are usually made using high-strength steel alloys. These materials provide durability and strength.

Dimensions

Dimensions of wheel hub forgings are determined by the vehicle type and wheel size. Important dimensions include the hub diameter, mounting surface, and width.

Load capacity

Load capacity refers to the maximum load the wheel hub can handle. This specification is important to ensure safety and prevent failure under heavy loads.

Tolerances

Precision manufacturing processes are used to produce wheel hub forgings. As a result, tight tolerances are required for dimensions and surface finishes.

Surface treatment

To protect wheel hub forgings from corrosion, surface treatments such as galvanization or coating are applied. These treatments also enhance wear resistance.

Quality standards

Quality standards must be adhered to during the production of wheel hub forgings. These standards include safety, reliability, and performance.

Regular maintenance of automobile wheel hub forgings is essential to ensure safety and reliability. Here are some important maintenance tips:

Quality of Material

High-quality raw materials are crucial for producing durable automobile wheel hubs. Generally, forged steel hubs are more robust than those made from other materials. Nonetheless, the choice of material for the wheel hub should align with the needs of the vehicle. For instance, lighter materials like aluminum may be ideal for racing vehicles, while forged steel hubs would be more appropriate for off-road 4x4 vehicles.

Quality of Workmanship

Quality of workmanship refers to the quality of the processes and the attention to detail during the production of the automobile wheel hub. Premium workmanship results in consistent quality of wheel hubs, which enhances their durability and performance. Quality of workmanship also influences the precision and accuracy of the wheel hub components, which minimizes vibrations and imbalances. Thus, quality of workmanship improves the overall performance of the wheel hub and enhances the driving experience.

Design

Design plays a pivotal role in determining the performance and durability of the automobile wheel hub. This is because the design needs to align with the specifications and requirements of a particular vehicle. This includes factors such as the size of the wheel, the number of lug bolts, and the offset. Additionally, the design of the wheel hub should consider the driving conditions and the type of vehicle. For instance, a 4x4 vehicle that drives on rough roads needs a more robust and durable wheel hub design than a race car.

Quality Control

Quality control is an important aspect of the production of automobile wheel hubs. It ensures that the forged wheel hubs meet the required quality standards and specifications. Quality control is crucial in every stage of the production process, starting from material selection to the final inspection of the wheel hub. Quality control helps in the detection and elimination of defects and inconsistencies. This enhances the reliability and performance of the wheel hubs.

Vehicle Compatibility

The wheel hub is a vital part of the vehicle's wheel system. Therefore, it is important to select a suitable wheel hub that is compatible with the vehicle. This is important because the wheel hub needs to fit perfectly with the other parts of the wheel system, such as the axle and the wheel. A compatible hub for the wheel ensures a seamless connection between the wheel and the vehicle body, enhancing driving stability and safety.

Price

Price is an important factor to consider when choosing the automobile wheel hub. Generally, more costly forged wheel hubs have better quality, performance, and durability than cheaper alternatives. Nonetheless, buyers should select wheel hubs that are suitable for their needs and requirements. This is because more premium forged wheel hubs come with advanced features and technologies, which might be more than what some buyers need.

Changing a wheel hub can be a DIY-friendly task. Here's a step-by-step guide on how to do it:

Test drive the car to confirm that the hub replacement was successful. After driving for a short while, check the hub nuts to ensure they are still adequately torqued.

Q1: What is an automobile wheel hub forging?

A1: Wheel hubs are small but important parts of a vehicle. They connect the wheels to the rest of the car. Hubs that are forged are made using a special technique called forging, which makes them really strong. This is important for safety because strong hubs help keep the wheels in the right place, even when driving on bumpy roads or in bad weather. A strong wheel hub can improve safety by keeping the wheels in the right place, even in tough conditions. This is important for features like ABS (Anti-lock Braking System) and ESC (Electronic Stability Control), which rely on precise wheel hub data to function effectively. The durability of forged wheel hubs also contributes to overall vehicle safety by reducing the risk of hub failure in critical situations.

Q2: What is the process of automobile wheel hub forging?

A2: The forging process involves several key steps to transform raw materials into strong and reliable wheel hubs. First, metal pieces called billets are heated until they are soft. Then, they are placed into molds that shape them into the basic form of the wheel hub. After that, a machine with powerful tools presses and hits the shaped pieces to make them even more solid and remove any air bubbles or weak spots. Finally, the finished hubs are cooled down gradually to make them even tougher. This process creates wheel hubs that can handle heavy loads and keep the wheels connected to the car securely.

Q3: What materials are commonly used in forged wheel hubs, and why are they chosen?

A3: Forged wheel hubs are usually made from strong metals like carbon steel or alloy steel. Carbon steel hubs are popular because they combine strength and affordability. Alloy steel hubs have extra elements like chromium or molybdenum, which make them even tougher and better at handling heavy loads. These materials are chosen for their durability and ability to withstand the stresses of driving, ensuring the wheels stay connected to the vehicle securely.

Q4: What is the difference between forged and cast iron wheel hubs?

A4: Forged and cast iron wheel hubs are two different methods of making hubs, and each has its pros and cons. As mentioned earlier, forging creates wheel hubs that can handle heavy loads and keep the wheels connected to the car securely.

On the other hand, cast iron hubs are made by pouring molten iron into molds. This method is more affordable but may not produce hubs as strong as forged ones. To put it simply, forged hubs are more expensive because they are stronger and more reliable.