(578585 products available)

Market Overview: The global market for automatic capping machines has been witnessing substantial growth, with the segment projected to reach approximately $978.6 million by 2030, growing at a CAGR of 3.4% from 2023. This growth trajectory is supported by a notable demand for automated packaging solutions across various industries, including food and beverage, pharmaceuticals, and cosmetics. In 2023, the U.S. market for such machinery was valued at around $203.1 million, while China is expected to experience a CAGR of 3.3%, reaching approximately $157.5 million by 2030, according to Global Industry Analysts. The rising emphasis on operational efficiency and the reduction of manual labor in manufacturing processes are key drivers propelling the adoption of automatic capping machines globally.

Industry Insights: The consumer behavior shift towards faster, more efficient packaging solutions has led to increased investments in automatic capping technologies. Companies are also focusing on enhancing production capabilities to meet growing demands, as evidenced by the expected growth of the automatic machines segment to $591.4 million by 2030, with a CAGR of 3.6%. Distribution channels are evolving, with manufacturers increasingly favoring e-commerce platforms like Alibaba.com to reach a broader audience, streamline procurement processes, and reduce lead times. Moreover, the integration of advanced technologies such as IoT and AI in automatic capping machines is anticipated to further optimize operations, improve accuracy, and reduce downtime, making these machines essential in modern manufacturing environments.

An automatic capping machine is an essential machine for any production line that involves bottling liquids or granular products into bottles. This machine is crucial for ensuring that the caps on the bottles are correctly fitted, possibly with added torque control for safety and tamper evidence.

Depending on the capping method used and the type of cap to be fitted, various types of automatic capping machines are available. They can broadly be classified according to the capping method into six categories:

Spindle capping machines

These capping machines are used for screw caps with horizontal or vertical capping heads. They are suitable for fitting various types of screw caps onto bottles. Spindle capping machines are further divided into either clutch or brake types. The clutch type uses a clutch-based slip to stop the spindle's rotation when it is driving a screw cap onto a bottle. On the other hand, brake spindle capping machines use a brake-based slip to stop the rotation of the spindle.

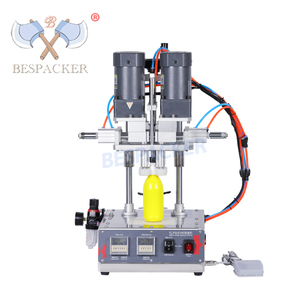

Snap capping machines

They are fitting snap caps with or without alignment features. For example, they could be used for plastic caps on beverage bottles.

Wadder capping machines

These capping machines are used for bottles requiring internal or friction caps. Internal caps have applying features, while caps require applying bottles only can be used with wadded capping machines.

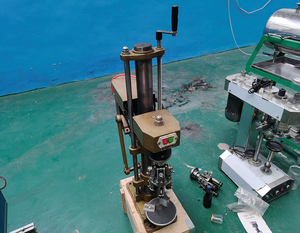

Pick and place capping machines

These capping machines are used to fit caps requiring custom or tamper-evident snap caps. They use a pre-torque system to Remolade a bottle before applying a cap to it.

Non-cap closure systems

These closure systems do not require caps, e.g., straws and flip-top closures used in sports bottles. They are based on alignment and sometimes applying closure systems using pneumatic or other mechanical methods.

Other ways of classifying the automatic capping machine include the feed method and cap application. The feed method includes capping machines that are funnel-fed or oriented. Capping machines that are oriented use star wheels, fixture lanes, or other methods to correctly position the caps onto the bottles. On the other hand, funnel-fed capping machines use gravity to position the caps correctly onto the bottles.

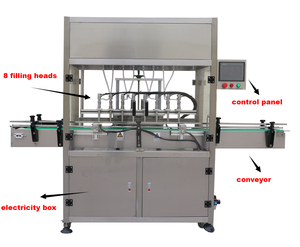

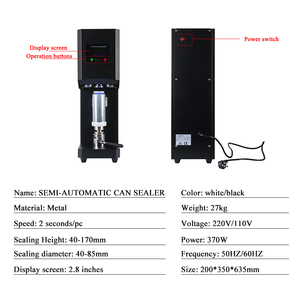

When applying the cap is the focus, the whether capping machine is an integrated system or stand alone is used to differentiate the capping machines. Stand alone capping machines are used in smaller production lines. In contrast, integrated capping machines with torquing systems are used for bottling lines with a higher throughput.

Generally, the specifications of an automatic bottle capping machine will depend on the model and type of machine. However, a general idea of what to expect is as follows:

Production Capacity

An automatic capping machine has a higher production capacity than manual capping equipment. While the exact production speed will depend on the machine's model, it typically ranges between 80 and 300 bottles per minute. That said, some specialized machines can cap up to 600 bottles per minute.

Capping Speed

An automatic capping machine comes with adjustable capping speeds. This allows operators to change the speed to match the speed of the bottling line and ensure precise cap application.

Applicable Bottles

An automatic capping machine can work with different types and shapes of bottles. The machine's design ensures it can accommodate varying sizes and shapes of bottles with no instability during the capping process.

Power Supply

Generally, an automatic capping machine works with electricity. The specific power requirements will depend on the machine's model and design. As mentioned earlier, some capping machines use air pressure (pneumatic) for cap application.

As mentioned earlier, the automatic capping machine requires regular maintenance to ensure it operates optimally and has a long lifespan. The machine's maintenance schedule will depend on the maintenance requirements of the manufacturer. Below are some routine maintenance tips for an automatic capping machine:

The usage of automatic capping machines transcends the bottling industries as they serve multiple sectors. Nonetheless, the key to their successful application in varied fields is selecting the most suitable kind based on the distinct properties of each production line.

In manufacturing industries, ranging from pharmaceuticals to food and beverages, automatic capping machines play a pivotal role in ensuring uniformity and precision in cap application.

To select the right capping machine, the following factors of the machine and the production requirement need to be considered.

Production speed

The production speed of the bottle capping machine must be compatible with the bottle-stuffing pace to ensure a seamless and efficient workflow. It's critical to evaluate the machine's maximum capping speed and ascertain whether it meets production demands. For reference, capper machines with higher speeds tend to be more expensive.

Applicable bottle caps

Ensure the automatic capping machine can accommodate the size, shape, and material of the bottle caps used in the production line. Different machines are designed to handle specific types of caps, so it's essential to verify compatibility. Also, consider the changeover process for adjusting the machine to handle different caps if there is a need to.

Bottle types

Check the compatibility of the bottle types that the automatic bottle capping machine can handle. Consider factors such as bottle material, shape, and stability, which may impact capping effectiveness and precision. Automatic capping machines are suitable for high-output bottling lines, and particular models may be preferred based on the bottle shape.

Machine dimensions and weight

Consider the dimensions and weight of the automatic bottle capper machine to make sure it will fit in the factory space and can be moved easily.

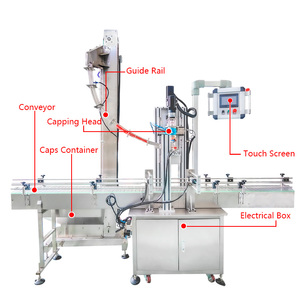

Control system and automation level

Consider the machine's control system and automation level, as this may impact user-friendliness, monitoring capabilities, and integration with other production line components. Think about the maintenance and support requirements for the capping machine. Determine the availability of spare parts, repair services, and technical support to ensure timely assistance when needed.

Q1: What is an automatic capping machine used for?

A1: An automatic capping machine is used to cap containers, bottles, and jars with different types of caps. It is commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals to ensure secure and consistent capping at high production speeds.

Q2: What are the benefits of using an automatic capping machine?

A2: Using an automatic capping machine offers several benefits, including increased capping speed and efficiency, improved capping accuracy and consistency, reduced labor costs, enhanced product quality and security, and greater flexibility and adaptability to different production requirements.

Q3: Can an automatic capping machine handle different types of caps?

A3: Yes, most automatic capping machines are designed to handle a wide variety of caps, including screw caps, snap caps, press-on caps, corks, and lift-off caps. They can accommodate different cap sizes and shapes with adjustable or interchangeable capping heads and changeparts.

Q4: Is it easy to maintain and clean an automatic capping machine?

A4: Yes, automatic capping machines are designed for easy maintenance and cleaning. Regular maintenance ensures optimal performance and longevity. Some maintenance tips include using appropriate lubricants, frequently checking and replacing worn parts, and routinely cleaning the machine to prevent product buildup and contamination.