Introduction to Atomizing Chip

The atomizing chip is a crucial innovation in various industrial applications, notably in the fields of electronics, healthcare, and manufacturing. This small yet advanced device works on the principle of creating fine mist or sprays from liquids, which can be essential for a number of processes. Whether used for coatings, medication delivery, or sensors in smart technologies, the versatility of atomizing chips has made them indispensable in modern technology.

Types of Atomizing Chips

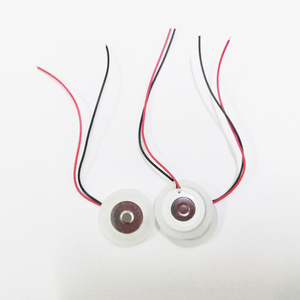

Atomizing chips come in several varieties, each designed to serve specific applications and requirements:

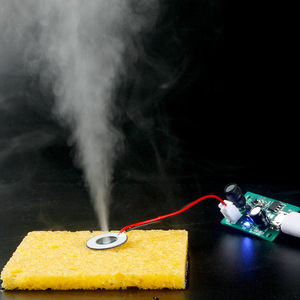

- Ultrasonic Atomizing Chip: Uses high-frequency sound waves to create fine droplets, ideal for humidifiers and medical nebulizers.

- Piezoelectric Atomizing Chip: Utilizes piezoelectric materials to create vibrations, making it suitable for perfumes and fragrances.

- Electrostatic Atomizing Chip: Operates by applying an electric charge to liquid droplets, often used in spray painting and agricultural applications.

- Thermal Atomizing Chip: Employs heat to vaporize liquids into fine particles, commonly found in e-cigarettes and aerosol delivery systems.

Function and Features of Atomizing Chips

Atomizing chips are designed with various features that enhance their functionality across different industries:

- Micro-Misting Capability: Creates extremely fine mist, improving the effectiveness of sprays, especially in healthcare and beauty products.

- Energy Efficiency: Many modern atomizing chips are designed to operate using minimal energy, which is vital for battery-operated devices.

- Variable Droplet Size: Some chips offer adjustable droplet sizes, catering to different application needs from delicate cosmetics to industrial coatings.

- Durability and Longevity: Built with materials that withstand wear and tear, ensuring long-lasting performance even in demanding environments.

Applications of Atomizing Chips

The applications of atomizing chips are diverse and impactful, delivering solutions in numerous sectors:

- Healthcare: Used in nebulizers for medication administration, ensuring optimal drug delivery right to the lungs.

- Beauty and Cosmetic Industry: Atomizing chips are used in spray bottles for fragrances and skincare products, providing even and fine application.

- Agriculture: Essential in crop spraying for pesticides and fertilizers, maximizing efficiency by producing finer, more uniform sprays.

- Electronics: Employed in sensors and cooling mechanisms, providing effective heat dispersion and enhanced environmental controls.

Advantages of Atomizing Chips

Utilizing atomizing chips offers various benefits across industries:

- Improved Efficiency: By creating fine particles, atomizing chips increase the surface area of the liquid, facilitating faster and more thorough coverage or absorption.

- Minimized Waste: Fine atomization reduces overspray and spillage, ensuring that valuable liquids are used effectually.

- Enhanced User Experience: Their compact and efficient design allows for easy integration into products, providing a seamless experience for end-users.

- Customized Solutions: With multiple types available, users can choose an atomizing chip tailored to their specific requirements, enhancing operational efficiency.