Growth Insights in the Assembly Machine Market

Market Overview: The assembly machine market has shown robust growth, increasing from USD 2.98 billion in 2023 to USD 3.23 billion in 2024. This upward trajectory is expected to continue, with projections estimating a compound annual growth rate (CAGR) of 8.47%, reaching USD 5.27 billion by 2030, according to 360iResearch. The surge in demand for automation and efficiency in manufacturing processes across various industries, particularly automotive and electronics, is a significant driver of this growth. As industries increasingly adopt advanced assembly technologies, the need for precision and speed in production is more crucial than ever.

Regional Insights: The global market dynamics reflect varying growth rates across regions, with Asia-Pacific leading the charge due to rapid industrialization and a burgeoning manufacturing sector in countries like China and India. The emphasis on automation and technological advancements in these regions aligns with the growing consumer electronics and automotive industries. In contrast, North America, recognized for its advanced manufacturing capabilities, is also witnessing a steady increase in assembly machine adoption, driven by the aerospace and automotive sectors. The market is characterized by fierce competition among key players, who are innovating to meet the evolving demands of precision assembly and efficient production processes. This competitive landscape is fostering a culture of continuous improvement and technological advancement in assembly machinery.

Types of assembly machines

An assembly machine refers to a machine used for the assembling part of goods. It may be a part of an assembly line or function uniquely, equipped with various tools. Many of these machines are programmed to assemble anything from toys to electronics to automobiles and much more. There are different types of assembly machines, such as:

- Manual Assembly Machine: In these types of machines, assembly is done by humans. These unassisted assembly machines can be cost-effective and useful for small production runs or delicate products that require attention to detail.

- Semi- Automated Assembly Machine: Semi-automated assembly machines have some automated parts, such as conveyor belts or robotics, which assist human workers in assembling products. They could be beneficial for coming up with products that need flexibility and quick changes in production.

- Automated Assembly Machines: Automated assembly machines have computer controls and robotics. They are helpful for large-scale production runs and more efficiency and repeatability.

- Flexible Assembly Machines: Flexible assembly machines can assemble various products without changing the system. This machine has the benefit of being adaptable for upcoming products that may enter the market.

- Pick-and-Place Assembly Machines: Pick-and-Place Assembly Machines are often used in electronics manufacturing to move parts from one location to the following, with High-precision,(functional) equipped with vision systems and control., thresholds. They can assemble parts in a later stage of a production line.

- Rotary Assembly Machines: In a rotary assembly machine, the work is done in a circular motion and puts parts into place at fixed intervals. These machines are well suited for quickly and efficiently assembling products that need identical parts to be put together in a specific way, like watches and small electronic devices.

- Linear Assembly Machines: Linear assembly machines have parts of a product that need to be put together one after another in a continuous flow. These are suitable for meeting products in high volumes needing consistency and speed.

- Collaborative Assembly Machines: Collaborative assembly robots, also known as cobots, are designed to work alongside human operators in assembly processes. They combine automation and human collaboration, assisting or augmenting human efforts rather than replacing them entirely.

Specification and maintenance of assembly machines

Generally, the specifications of an assembly machine vary depending on the application and type. Below are some key specifications along with their descriptions:

- Production speed: The production speed of an assembly machine indicates the speed at which an assembly product is created by the machine. The speed is usually measured in a specified number of assemblies products per hour or minutes.

- Product compatibility: An assembly machine is compatible with particular assembly products. The assembly product may include size, shape, and specifications.

- Accuracy and precision: The machine's accuracy and precision are critical when achieving the required assembly proportions and quality. The assembly machine's precision may be measured in millimeters or micrometers.

- Automation level: The automation assembly machine level may comprise fully automatic, semi-automatic, or manual operation. Generally, a fully automatic assembly machine offers a higher efficiency level and productivity.

- Power requirement: An assembly machine may require a specific power depending on the assembly product and machine type. It may range from small motors to industrial electrical drivers.

- Machine dimension: The dimension or size of the assembly machine may affect the assembly product's ability, space, and suitability.

- Additional functions: Some assembly machines may offer other functions and features customized according to particular assembly needs. This may include quality inspections, product tracking, and suction assembly techniques.

As the specifications of an assembly machine vary depending on the type and application, it is essential to consult the manual provided by the manufacturer when choosing the right assembly machine for one's needs.

Maintaining an assembly line machine properly helps to ensure fluent operation and prevent breakdown or downtime. Below are some key assembly machine maintenance tips:

- Regular inspection and adjustment: Regularly inspect the assembly line machine parts, such as the belt, driver, motor, bearing, and roller, to ensure fluent movement without obstruction. One can also make adjustments and align the parts to improve their accuracy and efficiency.

- Cleaning: Regular cleaning of the assembly machine component is also essential to avoid build-up dust, debris, and oil that can cause the assembly machine to malfunction or degrade the product quality.

- Lubrication: Regular lubrication of the moving parts ensure that they operate smoothly and freely while minimizing the tear and wear.

- Cooling: An assembly machine requires cooling to prevent overheating. One can install a cooling fan or a cooling system to regulate the temperature.

- Repair and replacement: It is essential to monitor wear and tear of the assembly machine components and parts over time. Pay attention to any signs that may require replacement, such as noise, vibration, failure to function right, and delay response.

Usage scenarios of assembly machines

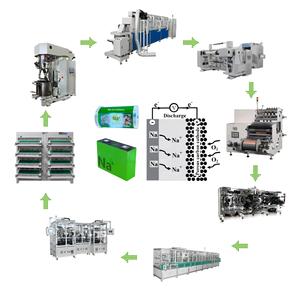

Assembly machines are flexible industrial automation tools that can efficiently and accurately perform a wide range of applications and tasks in various assembly scenarios.

- Product Assembly: Assembly machines are extensively used in manufacturing, such as electronic products, household appliances, automobiles, and more. They are used to assemble various parts, components, and accessories to make complete products.

- Precision Assembly: Some assembly machines are used for precision assembly, such as assembling medical devices, optical instruments, precision instruments, etc. These assembly machines usually have higher accuracy and are equipped with specialized fixtures and tools to ensure the correctness and reliability of precision assemblies.

- Multi-variant Assembly: Assembly machines also adapt to multi-variant assembly scenarios. For example, in the assembly of automobiles and aircraft, different models and specifications need to be assembled. Assembly machines can change the fixtures and tools to adapt to different assembly needs, which improves assembly flexibility and efficiency.

- Light-duty Assembly: Assembly machines are used for light-duty assembly scenarios, such as the assembly of electronic products, small appliances, crafts, etc. These assembly machines usually have a compact design and lighter weight, making them suitable for operation in limited space and low floor loading conditions.

- Complex Assembly: Assembly machines with multiple workstations and assembly processes are used to assemble complex products. For example, convertible assembly lines can be used to assemble complex products such as complete automobiles, aircraft, large industrial equipment, etc.

- Subassembly: Assembly machines can also be used in subassembly scenarios, such as assembling a subassembly to be further assembled in a main assembly line. For example, assembly machines can assemble specific components or assemblies, such as electronic circuits, valve assemblies, gearbox assemblies, etc., which are then supplied to other assembly lines for further processing.

- Modular Assembly: Assembly machines can be assembly scenarios of modular assembly, such as assembling standard modules or units into a complete system or equipment. For example, assembly robots can assemble modular components such as electronic control modules, drive modules, functional units, etc., which are then integrated into a complete system.

Choosing the right assembly machine

Choosing the correct assembly machine requires careful consideration of various factors to ensure the selected machine meets particular needs. Here are some key factors to consider when buying an assembly machine:

- Production requirements: This includes the volume, product types, and assembly complexity. One should consider their production requirements and choose the assembly model that matches the specified needs. For instance, a high-volume facility assembling a complex electronic device may require a different type of assembly machine than a low-volume workshop assembling simple mechanical products.

- Flexibility and scalability: It is essential to consider whether the assembly machine can be adapted to accommodate changing production needs. This may involve looking at the machine's reconfigurable assembly lines, interchangeable components, and modular design.

- Automation and technology: Consider the level of automation and advanced technology integrated into the assembly machine. Assess the machine's ability to integrate with existing production systems, such as enterprise resource planning (ERP) and manufacturing execution systems (MES).

- Floor space and layout: Consider how much floor space and layout is available. The assembly machine chosen should fit in the available space and work well with other production equipment.

- Ease of use and maintenance: Consider how easy it will be to operate and maintain the assembly machine. Look for machines with user-friendly controls, intuitive interfaces, and straightforward setup procedures. Also, consider the machine's maintenance requirements, such as routine maintenance tasks, servicing accessibility, and the availability of spare parts.

- Cost: Finally, the buyer's upfront assembly machine cost, and long-term operating expenses, including maintenance costs, energy consumption, and spare parts required, are to be considered. While the initial investment is essential, long-term operating costs can significantly impact the overall cost of the assembly solution.

FAQ

Q1: Which products use an assembly machine?

A1: An assembly machine can produce various items. It can put together complicated things like cars and cell phones or simpler stuff like clocks and pencils.

Q2: Do assembly machines make errors?

A2: Assembly machines help people make things faster and cheaper. But they sometimes make mistakes. Improving the machine's design and programming can reduce these errors. Regular maintenance is also important.

Q3: Can assembly machines be modified?

A3: Yes, assembly machines are adaptable. Changing their setup helps them make different products. However, changing them can take time and cost.

Q4: Do assembly machines need maintenance?

A4: Yes, regular maintenance is essential for assembly machines. It keeps them operating efficiently and prevents breakdowns. Consider a maintenance schedule for the machine.