Introduction to Antistatic Conductive Bags

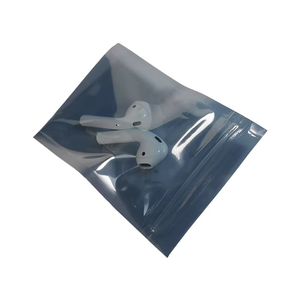

Antistatic conductive bags play a crucial role in safeguarding electronic components and sensitive devices from electrostatic discharge (ESD). These specialized packaging solutions are designed to ensure that delicate items, such as circuit boards, semiconductors, and other electronic components, remain protected during transport and storage.

By creating a controlled environment that dissipates static electricity, antistatic conductive bags are indispensable for manufacturers, suppliers, and retailers dealing with electronic products. Understanding their structure, types, and applications is essential for optimizing their benefits.

Types of Antistatic Conductive Bags

There are several types of antistatic conductive bags, each tailored to meet varying needs within the electronics industry:

- Conductive Polyethylene Bags: Made from a blend of low-density polyethylene and conductive additives, these bags provide excellent static protection while remaining lightweight and flexible.

- Metalized Foil Bags: These bags feature a layer of metalized film that offers superior defense against electromagnetic interference (EMI) along with ESD protection, making them ideal for high-precision devices.

- Anti-Static Bubble Bags: Combining cushioning with static protection, bubble bags are designed for fragile components, ensuring they are not only static-free but also secured against physical damage.

- Static Shielding Bags: Equipped with a multi-layer construction, these bags shield items from both static and RF interference, providing a comprehensive protective solution for sensitive electronics.

Applications of Antistatic Conductive Bags

Antistatic conductive bags are extensively utilized across various sectors where ESD protection is paramount:

- Electronics Manufacturing: They are vital in the production line, where electronic parts are at risk of static charges during assembly.

- Transportation of Electronic Components: These bags ensure that products remain safe from static discharge during shipping, minimizing potential damage.

- Storage Solutions: They allow for secure storage of sensitive devices, whether in retail or warehousing environments, prolonging component lifespan.

- Repair and Service Centers: Technicians use antistatic conductive bags to protect repaired items, ensuring they remain safe from ESD before they reach customers.

Advantages of Using Antistatic Conductive Bags

Adopting antistatic conductive bags offers numerous benefits to businesses and consumers alike:

- Enhanced Protection: They effectively prevent static electricity build-up, safeguarding sensitive electronic devices from potential damage.

- Cost-Effectiveness: By prolonging the life of electronic components, these bags can help reduce replacement costs and minimize losses in production.

- Versatile Applications: They are ideal for a wide range of items, from small components to larger devices, making them a versatile solution for various needs.

- Easy Identification: Many bags come with clear labels and color coding, allowing for quick identification and organized storage of components.

- Sustainability: Many antistatic bags are recyclable, contributing to environmentally-friendly packaging practices.