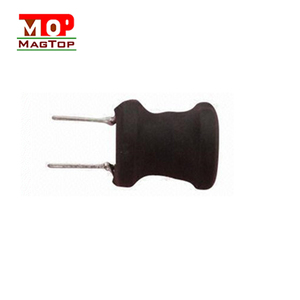

Introduction to Anti Vibration Bobbin Mounts

Anti vibration bobbin mounts are essential components designed to reduce vibration and noise within various industrial and automotive applications. By effectively isolating vibrations, these mounts contribute to enhanced operational efficiency and prolong the lifespan of machinery and equipment. Understanding the characteristics and functionalities of anti vibration bobbin mounts is crucial for selecting the right solution for your specific needs.

Types of Anti Vibration Bobbin Mounts

Anti vibration bobbin mounts come in a variety of forms, tailored to address different application requirements. Here are some common types:

- Rubber bobbin mounts: These mounts utilize rubber to absorb vibrations and are ideal for general use in light to medium vibration environments.

- Metal bobbin mounts: Featuring a combination of metal and rubber, these mounts provide durability and strength, suitable for heavier machinery.

- Hollow bobbin mounts: Designed with a hollow center, these mounts offer greater flexibility and are effective for mitigating high-frequency vibrations.

- Adjustable bobbin mounts: These versatile mounts can be adjusted to accommodate specific vibration damping needs, making them suitable for varied use cases.

Applications of Anti Vibration Bobbin Mounts

Anti vibration bobbin mounts find their use across a myriad of industries owing to their vibration dampening capabilities. The following are prominent applications:

- Automotive sector: Used for mounting engines and suspensions, these mounts help in minimizing noise, vibration, and harshness (NVH) levels.

- Manufacturing equipment: They are employed in machines to protect sensitive components from wear caused by vibrations, enhancing productivity.

- HVAC systems: In heating, ventilation, and air conditioning systems, these mounts prevent operational vibrations from transmitting through building structures.

- Electronics and telecommunications: In delicate electronic equipment, anti vibration bobbin mounts safeguard components from vibrations that could lead to malfunction.

Features and Advantages of Anti Vibration Bobbin Mounts

The importance of anti vibration bobbin mounts cannot be overstated, as they offer a range of features and advantages that enhance performance:

- Noise reduction: By isolating vibrations, these mounts significantly reduce operational noise, creating a more pleasant environment.

- Durability: Made from high-quality materials, they boast excellent wear and tear resistance, providing long-lasting performance even in challenging conditions.

- Enhanced performance: Reduced vibrations lead to increased efficiency and better performance of machinery, resulting in lower maintenance costs.

- Versatility: Available in multiple sizes and configurations, anti vibration bobbin mounts can be adapted to fit a wide range of applications and equipment.