All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(32358 products available)

Market Overview: The anodizing titanium machine market is poised for substantial growth, paralleling trends in the broader die casting machinery sector. According to Research and Markets, the die casting machinery market expanded from USD 3.10 billion in 2023 to USD 3.34 billion in 2024, with projections indicating a CAGR of 7.98% to reach USD 5.31 billion by 2030. This growth is fueled by increased applications in aerospace and automotive industries, where titanium's lightweight and corrosion-resistant properties are highly valued. Additionally, the rise in microelectronics and the miniaturization of components further drive demand for advanced anodizing processes, which enhance surface properties of titanium components.

Industry Insights: Key players in the anodizing titanium machine market are focusing on innovation and efficiency to capture market share. The integration of AI and automation technologies is transforming manufacturing processes, making them more cost-effective and precise. As consumer preferences shift towards sustainable and high-performance materials, manufacturers are adapting their strategies accordingly. The Asia-Pacific region is emerging as a pivotal market due to its robust electronics and automotive sectors, particularly in countries like China and Japan. However, challenges such as the technical complexity of anodizing processes and a shortage of skilled technicians remain key pain points for industry players. Addressing these challenges will be crucial for companies aiming to leverage growth opportunities in the anodizing titanium machine market.

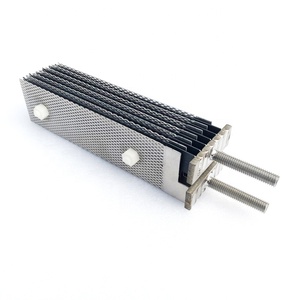

An anodizing titanium machine is equipment used to carry out anodizing, which is an electrochemical process. It is used to coat titanium metal surfaces with oxide layers. This oxide layer is beneficial as it enhances the metal's surface properties, like corrosion resistance, wear resistance, and aesthetic qualities.

Since titanium is used in military-grade metals in weaponry, the machines for anodizing titanium vary. They are not just used to achieve any surface coloration, but there is a need to improve the underlying metal's surface and physical characteristics. So, depending on industry requirements, different anodizing machines accomplish various purposes.

These machines can be categorized into four broad types:

There are other specialized anodizing machines for titanium. These machines help achieve specific results depending on the project's requirement. Some of these may only be available as custom requests.

The titanium anodizing machine specifications and features vary depending on the type and model of the machine. Here are some of them.

Small titanium anodizing machines usually have a power supply of about 10 to 20 volts. This is enough to produce the thin oxide layers required to create the desired colors in the titanium parts. Larger machines have higher power requirements. For instance, barrel anodizers have a power requirement of between 40 to 80 volts. Load capacity is another vital titanium anodizing machine specification. Load capacity is the weight of titanium parts the machine can process at a go. Smaller anodizing machines process about 1 kg of titanium parts per load. Larger machines such as barrel anodizers process up to 250 kg of titanium parts per load.

In terms of dimensions, smaller anodizing machines measure about 1 to 2 meters in length and about 1 meter in width. Larger machines are bigger and take up more floor space. They can measure up to 4 meters in length and 2 meters in width.

Aside from these specifications, the machines have various safety features, such as emergency stop buttons. They also have filtration systems and fume extraction methods to minimize exposure to hazardous materials like lead, arsenic, nickel, and carcinogenic substances.

Many titanium anodizing machines have digital controllers that allow precise control of voltage and temperature. This leads to consistent results. Some machines also have timer functions so operators know how long to subject the titanium parts to the anodizing solution for.

The applications of titanium anodizing machines are wide and varied, especially in industries where titanium is found. The aerospace industry uses titanium very much because it is both light and strong. The machines are used to coat aircraft parts and other accessories so that they can be protected from corrosion.

The medical field also uses these machines. Implants and other accessories are anodized to improve the quality of the surface and to increase biocompatibility.

Many industries that use titanium benefit from titanium anodizing machines. Jewelry makers also use the machines to produce beautiful and vibrant colored titanium jewelry.

The beauty about titanium anodizing machines is that they can also be used to anodize other metals, like aluminum. Aluminum is widely used in automotive, aerospace, construction, and packaging industries, so there is a high demand for anodizing machines. Anodizing improves aluminum's strength, durability, and corrosion resistance, making it suitable for these applications. When the machine is used to anodize aluminum, not only the functional characteristics, but also the aesthetic appeal, is improved. This enhances the product's market value, and more people are willing to pay a premium for it.

When choosing titanium anodizing machines for sale, buyers should focus on the most important features that the customers care about. This will ensure they are getting machines that will sell quickly.

First, buyers should get machines that can process different shapes. This includes rods, rings, tubes, and solid parts. Customers normally look for versatile machines that can meet different needs, so this feature will definitely appeal to them.

Second, buyers should get anodizing machines with variable voltage. This is an important feature for most customers to control the thickness and color of anodizing easily.

Another important feature buyers should consider when getting machines is safety. Customers want to see anodizing machines with safety features like overcurrent protection and emergency stop buttons. This will protect the operators from accidents and ensure safe operation.

Additionally, buyers should get machines that come with good instructions. Most customers who buy these machines will have to train their employees on how to use and maintain the machines. Therefore, when the machine comes with manuals and guides, it will be easier for the customers to train their employees. Also, the employees will have an easier time learning how to use and care for the machine.

More importantly, buyers should get machines that are easy to maintain and clean. The anodizing process can be quite complex and messy, so customers will want machines that are easy to take care of.

Finally, buyers should get anodizing machines in different sizes and models to suit various customers' preferences. Some customers will want large industrial machines with high capacities, while others will want small-benchtop models for small-scale production.

Q1: What materials can an anodizing machine use?

A1: Titanium anodizing machines are specially designed to work with titanium. Other metals cannot be used in these machines because the titanium anodizing process requires a specific set of conditions that may not be suitable for other metals, including the same voltage ranges that produce distinct colors on titanium.

Q2: How long does the titanium anodizing machine take?

Anodizing machines usually complete their tasks in one to fourteen minutes. Factors like the alloy, the thickness of the oxide layer required, the size of the part, and the anodizing color can all influence the time taken. For example, getting a gold color takes less time than other colors.

Q3: What are the three steps in titanium anodizing?

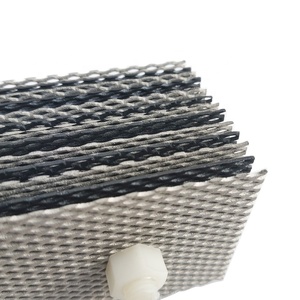

A3: There are three main stages in the titanium anodizing process - cleaning, anodizing, and sealing. First, the Titanium is cleaned, often by immersion in a solution. In some cases, the anodizing itself can also clean the Titanium. Second, during the anodizing part of the process, an electrical charge is sent through the Titanium in the anodizing bath. This creates a Titanium oxide layer that changes the appearance of the metal. Third, sealing involves the completion of the process. Not all anodizing processes require sealing. Still, for aluminum and other metals, sealing will be vital to lock in the color and enhance corrosion resistance.

Q4: What are the advantages of titanium anodizing machines?

A4: Titanium anodizing machines have several benefits. Unlike other coating methods, the anodized layer will have higher adhesion. The titanium color anodizing machine also offers a plethora of color choices for business customers to choose from. Unlike other methods, the anodizing process highlights the underlying metal structure, and in some cases, the titanium will remain lighter than other types of anodized metals. Another plus is that anodized titanium is more chemically resistant than titanium that has not been anodized. This chemical resistance can be crucial in certain applications.

Q5: What are the most important safety precautions when using titanium anodizing machines?

A5: There are a few safety precautions that must be taken when using these machines. The first is to wear the appropriate PPE, or personal protective equipment, which may include goggles, gloves, and masks. Second, ensure that there is adequate ventilation in the area where the machine is being used because harmful gases or chemicals may be present from the anodizing process. Third, conduct a risk assessment of the area and ensure that all safety measures have been taken to eliminate or reduce any risks.