(991 products available)

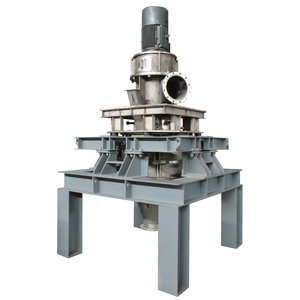

An air classifier is a milling machine designed to separate fine particles from bulk material using air streams. Air classifiers made in China are available in several types, each with a different working principle.

Spiral air classifier:

A spiral classifier uses a helical flight to lift the settled materials out of the classifier tank. The air classifier uses the gravitational force of the material and the centrifugal force of the classifier to separate the particles. It works well in separating relatively fine and light materials. The classifier can have different tank designs depending on the materials. Spiral classifiers are mainly used for the separation of heavy minerals.

Spiral classifier:

The spiral classifier has a screw-like structure that works with a settling tank. It uses the principle of buoyancy to separate materials with different densities. Nevertheless, the principle of buoyancy in water is what makes separation possible. The separating classifier equipment can have different sizes to suit various industrial applications.

Static air classifier:

This classifier uses gravity to settle particles within a chamber. It uses air blowers or fans to create an upward air stream that carries lighter particles. The classifier is then able to separate coarse materials that sink due to gravity. Static air classifiers are mostly used in the recycling industry.

Jet air classifier:

A Jet air classifier separates materials based on particle size and density. It creates an air stream using compressed air, which lifts light particles and ejects them through the outlets. Heavier particles fall into the inlet again. Jet classifiers can be used for the milling and classifying of minerals, powders, and pigments.

Classification:

Air classifiers are designed to separate particles of various shapes and sizes. They can achieve a precise classification of dry materials, including fine, coarse, and oversize particles, depending on the specific model and settings.

Materials:

Air classifiers can process a wide range of materials, such as calcium carbonate, cement, quartz sand, sodium bicarbonate, talcum powder, fly ash, graphite, industrial salt, etc., depending on the model and purpose.

Capacity:

The throughput, usually expressed in tons per hour, is determined by several factors, including the material's characteristics, the classifier's design, and the operating conditions.

Cut points:

This refers to the range of particle sizes that the air classifier can separate. This is usually expressed in microns or mesh sizes, e.g., D97=10μm, D50=5μm.

Precision:

Air classifiers can achieve varying degrees of precision from coarse to fine classifications, depending on the type of classifier and its operating parameters.

Components:

Air classifiers typically consist of several key components, including the feeding device (feeder), separation unit (classifier body), dust collection and conveying system (cyclone separator), and the classifier's control and adjustment system.

Classifier type:

As mentioned before, different types of air classifiers have distinct working principles and structures. For example, an air jet classifier will differ from a cyclone classifier.

Dimensions and weight:

The size and weight of an air classifier will depend on the classifier's type and model and its processing capacity and design.

Regular inspection:

Regularly inspect the classifier components for signs of wear and damage. Pay particular attention to key parts, such as the separation mechanism, the dust collection system, the fan, and the pipelines. If any issues arise, please address them promptly to prevent air classifier classifier malfunction from affecting the material separation effect.

Cleaning:

Timely remove the residual materials inside the air classifier and clean the dust. This prevents dust from accumulating and blocking the ventilation holes and pipelines, thereby avoiding dust pollution to the environment and protecting the air classifier's motor.

Lubrication:

Regularly lubricate the moving parts of the air classifier, such as bearings and transmission mechanisms. Use the proper lubricating oil or grease per the equipment manual requirements to ensure smooth operation and reduce wear.

Adjustment and debugging:

Regularly adjust and debug the parameters of the air classifier according to the characteristics of the processed materials and the desired classification precision to ensure the best classification effects.

Pay attention to temperature and pressure:

Monitor the operating temperature and pressure of the air classifier. Ensure they remain within the specified limits to prevent overloading or overheating issues.

Safety management:

When maintaining the air classifier, ensure the power is turned off. Also, follow the safety operation regulations to prevent accidents.

Due to their versatility, air classifiers find a wide range of applications in different industries.

Food industry

A nut classifier is one of the classifiers used to separate the different types of nuts based on their sizes. Nuts such as almonds, pecans, walnuts, and cashews have different sizes; hence the classifiers help to maximize yield and maintain product quality. The classifiers also help to minimize contaminants such as shells and foreign materials. In addition to classifiers, air separator classifiers have different uses in the food industry. For example, flour classifiers separate coarse particles of flour, which helps to improve the texture and quality. Sugar classifiers are used to separate sugar particles based on sizes. The air classifier mills are also used to separate starch and other food ingredients to obtain fine products.

Mineral industry

Air classifiers are used to separate minerals such as calcium carbonate, feldspar, barite, silica, and many others. They help to obtain a mineral with a specific size and purity. Powder classifiers, such as cement classifiers, are widely used in the construction industry. They separate cement and other mineral compounds according to size. The coal classifiers are also common in the mineral industry. They are used to obtain coal with a specific size that can be processed and combusted in power plants.

Recycling industry

Air classifiers are used in the recycling industry to separate valuable materials from contaminants. For example, plastic classifiers are used to separate plastics based on density and size. The classifiers also separate plastics from other materials, such as paper and glass. Air classifiers can be used to separate textiles, rubber, and other materials from unwanted ones.

Pharmaceutical industry

Air classifiers in the pharmaceutical industry separate drugs and chemical compounds by particle size. They improve the quality and ensure process efficiency. Additionally, pesticide classifiers are used to separate pesticides based on sizes to enhance formulations and control efficiency.

Fine powder manufacturing

Air classifiers are used to separate fine powders in industries such as carbon black, kaolin, and titanium dioxide. They play a crucial role in product development.

When choosing an air classifier, among the vast array of classifiers on Alibaba.com, it is imperative to keep several essential things in mind.

Materials and Particle Size:

It is crucial to consider the material and its particle size that the classifier is intended to separate. Each classifier is designed to work with specific materials and particle size ranges. Using the right classifier for the material and particle size will ensure efficient separation and prevent equipment damage.

Classifying Accuracy:

When selecting an air classifier, it is essential to consider its classifying accuracy. Different classifiers have varying levels of accuracy in separating particles based on their size and density. Choosing a classifier with the appropriate level of accuracy for specific materials and desired end products is important. This will ensure that the classifier can effectively separate particles with precision and meet the quality requirements for the intended application.

Air Flow Rate and Pressure:

When selecting an air classifier, it is important to consider the airflow rate and pressure at which the classifier operates. Different classifiers have varying airflow requirements for optimal separation. Choosing a classifier that matches the airflow rate and pressure of the existing air handling system is important. This will ensure proper functioning, efficient separation, and minimal pressure drops in the air distribution system.

Operating Environment:

It is crucial to consider the operating environment when selecting an air classifier. Classifiers are designed to work effectively in specific environmental conditions, such as temperature, humidity, and dust levels. Choosing a classifier suitable for the operating environment will maintain optimal performance, prevent equipment degradation, and ensure reliable separation under the given environmental conditions.

Maintenance Requirements:

Classifiers have varying maintenance requirements, such as cleaning frequency, lubrication, and calibration. Considering the maintenance requirements of the chosen classifier will help determine the necessary resources and time for upkeep. Selecting a classifier with manageable maintenance requirements can help minimize downtime, reduce maintenance costs, and ensure consistent classifier performance over time.

Q1: How does an air classifier work?

A1: An air classifier separates materials of different shapes, sizes, and densities by using air flow and gravitational forces. It typically consists of feeding devices, classifying chambers, separation units, collection devices, and exhaust systems. Raw materials enter the classifier through the feeder and spread evenly on the classifier. Air flow then lifts light particles, while heavy particles fall down due to gravity. Light particles move to the collector through the air outlet, and the others are recycled to the classifier for re-classification with the help of a rotating separator.

Q2: What are the trends in air classifier technology?

A2: The air classifier technology is developing in the direction of automation, integration, and energy saving. classifiers are now equipped with intelligent control systems that can realize automated classification processes. Moreover, the integration of classifiers and other processing equipment, such as crushers and mills, is becoming a mainstream solution. Meanwhile, classifiers are designed to consume less energy, thus achieving more environmentally friendly operations.

Q3: What are the advantages of air classifiers?

A3: The air classifier offers several advantages. First, it can process large amounts of materials and have high capacity. Second, it can separate particles with higher precision and more grades than traditional classifiers, such as spiral classifiers or screening classifiers. Third, the air classifier has a simple structure and occupies less space, making it easy to integrate into production lines.