All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2389 products available)

Ready to Ship

Ready to Ship

Acoustic felt fabric is a textile material commonly used in soundproofing and noise management applications. It's designed to reduce noise by absorbing sound waves, making it an essential component in various acoustical solutions. Acoustic felt fabric is primarily made from wool or polyester. Acoustic felt fabric is available in different types, as discussed below:

Wool Acoustic Felt:

This fabric is made from wool fibers. It can also be made from a blend of wool and synthetic fibers. Wool acoustic felt is preferred by many due to its excellent sound-absorbing properties. It is also environmentally friendly. Additionally, this fabric comes in different thicknesses and densities. These variations allow for customization based on specific acoustic needs. For instance, greater thickness and density improve sound absorption, especially in lower frequencies. Wool acoustic felt is also known for its durability. It can maintain its acoustic performance over time despite repeated use and exposure to various conditions.

Polyester Acoustic Felt:

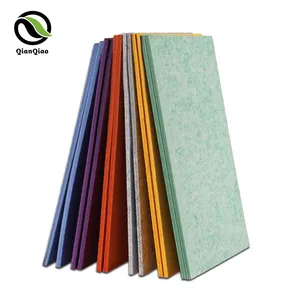

This type of felt is made from 100% recycled PET (polyethylene terephthalate) plastic bottles. It is a more widely used acoustic felt as it is cheaper to produce. It is also lightweight and versatile. Polyester acoustic felt is available in various colors. These colors range from neutral tones to bold hues that match different design requirements. Polyester acoustic felt is also easy to work with. It is available in various forms, such as sheets, panels, and rolls, which can be easily cut and shaped for different applications.

Composite Acoustic Felt:

This is a blend of different materials designed to enhance sound absorption. It typically combines synthetic fibers like polyester with natural fibers such as wool or cotton. Composite acoustic felt is suitable for applications requiring a balance of sound absorption and aesthetic appeal. For instance, it can be used as wall panels or room dividers. Additionally, it is available in various textures and finishes.

Mass Loaded Acoustic Felt:

This type of acoustic felt fabric incorporates denser materials. For example, it has vinyl or rubber. This increases its mass and improves soundproofing capabilities. Mass-loaded acoustic felt is ideal for applications requiring superior noise reduction. These applications include theater rooms and recording studios.

Acoustic felt fabric is a versatile material with various applications. Its primary function is to reduce noise levels. However, it has other functions as well. Below are some features of acoustic felt fabric.

Sound Absorption

Acoustic felt is primarily designed to absorb sound waves. It minimizes echo and reverb by reducing noise levels. Acoustic felt is made from polyester fibers or wool felt. These materials are known for their sound-absorbing capabilities. The structure of acoustic felt is dense and porous. This enables it to trap sound waves and prevent them from bouncing off surfaces.

Soundproofing

Acoustic felt fabric is used for soundproofing. It prevents outside noise from entering a room or space. Acoustic felt is durable and thick. When applied to walls, ceilings, or floors, it forms a barrier. This barrier blocks unwanted sound from coming in or leaving a room.

Noise Reduction

Noise reduction is the primary function of acoustic felt. It minimizes the overall noise level in a space. Lower noise levels create a more quiet and peaceful environment. A more peaceful environment is conducive for various activities like studying or working.

Eco-Friendly

The materials used to make acoustic felt are recycled plastics or natural wool fibers. These materials are sustainable. Acoustic felt fabric is 100% recyclable. This makes acoustic felt a good choice for designers or homeowners who are eco-conscious.

Versatility

Acoustic felt fabric comes in different designs, colors, and textures. This allows it to be used in different spaces. For instance, acoustic panels are made using acoustic felt. Acoustic panels are used in offices, concert halls, homes, and studios. Acoustic panels improve the aesthetic appearance of a space. Acoustic felt can also be used in furniture, partitions, and ceilings.

Easy to Install

Acoustic felt is user-friendly. It is easy to install. Acoustic felt comes with adhesive backing. This makes it easy to apply on different surfaces. Acoustic felt fabric can also be stapled or glued onto surfaces.

Acoustic felt fabric is used in different industries for various purposes. Here are some of its usage scenarios:

Office Spaces

Acoustic felt is widely used in corporate environments. It is used to create sound-absorbing partitions, office furniture, and wall panels. These solutions reduce noise and promote private conversations. Reducing noise in the workstations enhances focus and productivity.

Educational Institutions

Schools, Colleges, and Universities use acoustic panels and baffles made from felt fabric. The noise canceling properties of these products create quiet learning environments. They minimize sound interferences in classrooms. This helps students to concentrate and educators to deliver instructions effectively.

Hospitality Sector

Acoustic felt is an integral part of the hotel and restaurant design. It is incorporated in the ceiling, wall coverings, and custom-furnishings. These applications provide a calm and pleasant ambiance for diners and hotel guests. It also allows the seamless blending of noise control with aesthetic functions.

Healthcare Facilities

Reduction of noise is critical in medical environments. Acoustic felt fabric is used to craft wall coverings and partitions for hospitals and clinics. These products lower sound levels. They ensure a serene environment for patients' recovery and consultations.

Homes

Acoustic felt is extensively used in residential spaces. It is used to manufacture acoustic panels, soundproof doors and windows, and rugs. These applications enhance the overall aesthetic. They also reduce noise pollution from external environments. Most home theaters use the fabric to regulate acoustics. This ensures clear sound delivery and improves the movie watching experience.

Retail Outlets

Felt fabric is used in shops and stores to create acoustic solutions. These solutions control noise echoes and interferences. This creates a comfortable shopping environment. This encourages potential customers to make buying decisions.

Public Spaces

Acoustic felt is used in civic centers, libraries, and community halls. Here, it is integrated into architectural elements. These include ceilings, walls, and furnishings. It helps to maintain a serene environment for the functions of these spaces.

Broadcast Studios

Sound felt fabric is used in the communication centers. These include radio and television stations. It is integrated into the studio walls, ceilings, and furnishings. Acoustic felt absorbs sound waves. This minimizes echoes and reverberation. This ensures clarity and quality of sound recordings and broadcasts.

Places of Worship

Acoustic panels made of felt are used in churches and mosques. The panels reduce echoes and sound interferences. They ensure clear sound delivery. This is important during sermons, prayers, and communal gatherings.

When selecting acoustic felt fabric, there are several factors to consider to ensure it meets the desired performance requirements and aesthetic preferences. Here are some key considerations:

Sound Absorption

Look for acoustic felt fabrics specifically designed for sound absorption. These fabrics are usually made from polyester or wool blend, which are known to absorb sound waves effectively. Consider the NRC rating (Noise Reduction Coefficient) of the fabric. A higher NRC rating indicates better sound absorption.

Thickness and Density

Generally, thicker and denser felts provide better sound absorption, especially in lower frequencies. When choosing acoustic felt, consider the space's soundproofing needs. For higher frequency sounds, thinner felts may be sufficient. For more soundproofing, a denser and thicker acoustic felt should be chosen.

Flame Resistance

For many applications, it is important that the acoustic felt fabric is flame resistant. Check the manufacturer's specifications for the acoustic felt fabric to see if it has passed any relevant fire safety standards.

Breathability

Breathability is important when the acoustic felt is used in applications such as interiors of vehicles and wall coverings. Breathable acoustic felts prevent moisture buildup and promote air circulation.

Environmental Impact

Choose acoustic felt fabrics made from recycled materials or sustainable practices. Some manufacturers provide information about the environmental impact of their products. Consider the product's lifecycle from manufacturing to disposal.

Durability and Maintenance

Consider the durability of the acoustic felt fabric, especially in high-traffic areas. Look for fabrics that are tear-resistant and easy to clean. Check the cleaning instructions to determine if the fabric is washable or requires dry cleaning.

Aesthetics

Acoustic felt is available in various colors, textures, and finishes. Choose a fabric that complements the design of the space. Consider the fabric's application, whether it is used as a wall covering, acoustic panels, or partitions.

Cost

While performance is the main consideration, it is important to consider the budget. Acoustic felt fabrics are available at different price points. Weigh the cost against the desired performance and quality.

Q1: What are the characteristics of acoustic felt fabrics?

A1: Acoustic felt fabrics have unique features that are essential. First, they are made from wool, polyester, or recycled materials. They are lightweight and flexible, which makes them easy to handle and sew. Acoustic felt fabrics are available in different colors, which makes them suitable for aesthetic uses. They are also durable, meaning they can withstand regular use, and their edges can be finished to prevent fraying.

Q2: What are the uses of acoustic felt fabric?

A2: Acoustic felt fabrics are used in various applications due to their sound-absorbing capabilities. They are used in partitions, wall panels, office spaces, and ceilings for noise reduction. Acoustic panels are decorative and functional, improving sound quality. Acoustic felt is used in the automotive industry for sound insulation in vehicles. Acoustic felt is also used in the construction industry.

Q3: How is acoustic felt fabric maintained?

A3: Maintaining acoustic felt is simple. It involves regular cleaning using a soft brush to remove dust and debris. The fabric can be vacuumed using a handheld vacuum cleaner with a soft brush attachment. Deep cleaning can be done periodically using a professional cleaning service or acoustic panels.