Types of 90mm Engine Pistons

The 90mm engine piston comes in various designs optimized for different engine applications and performance requirements. Understanding these variations is crucial for proper engine building and maintenance.

Reciprocating Engine Pistons

The most common 90mm engine pistons found in both petrol and diesel engines. These pistons convert fuel combustion energy into mechanical energy by moving up and down in the cylinders.

Key feature: Connected to the crankshaft via piston rods, translating linear motion into rotational force

Rotary Engine Pistons

Unlike conventional pistons, rotary engines employ triangular-shaped rotors that spin in an eccentric motion within the combustion chamber, creating expanding and contracting chambers.

Key feature: Provides smoother power delivery with fewer moving parts

90mm Diesel Engine Pistons

Specially designed to withstand the higher compression ratios and pressures in diesel engines. These pistons feature robust construction to handle increased stress during combustion.

Key feature: Reinforced structure for durability under high-pressure conditions

90mm Turbo Engine Pistons

Engineered for turbocharged applications, these pistons incorporate advanced cooling features and high-strength materials to manage elevated temperatures and pressures.

Key feature: Enhanced thermal management and structural integrity

| Piston Type | Primary Application | Construction Features | Performance Characteristics |

|---|---|---|---|

| Reciprocating | Standard gasoline/diesel engines | Cylindrical design with rings | Balanced performance for everyday use |

| Rotary | Wankel and rotary engines | Triangular rotor design | Smooth power delivery, high RPM potential |

| Diesel | Heavy-duty and commercial engines | Reinforced crown, oil cooling galleries | High torque, durability under pressure |

| Turbo | High-performance and racing applications | Heat-resistant alloys, cooling channels | Withstands boost pressure, high-temperature operation |

Expert Tip: When selecting a 90mm piston type, consider not only your current performance needs but also your future tuning plans. Upgrading to a higher-spec piston initially can save costly engine rebuilds later if you plan to increase power.

Specifications and Technical Details

Understanding the technical specifications of 90mm engine pistons is essential for proper selection and application. These specifications determine compatibility, performance, and durability in your engine build.

Piston Diameter

The piston diameter (bore) measures the piston head's surface area. For 90mm pistons, this measurement is precisely 90mm, though manufacturing tolerances may apply for specific fitting requirements.

Piston Pin Diameter

This critical measurement must match the connecting rod specifications. For 90mm pistons, pin diameters typically range between 18mm and 30mm, depending on the engine application and load requirements.

Piston Height

The distance from the piston crown to the center of the piston pin. This measurement affects cylinder head clearance and compression ratio, typically ranging from 70mm to 90mm for 90mm pistons.

Piston Weight

A critical factor in engine balance and performance. 90mm pistons typically weigh between 200g and 600g, with performance applications often using lighter alloys to reduce reciprocating mass.

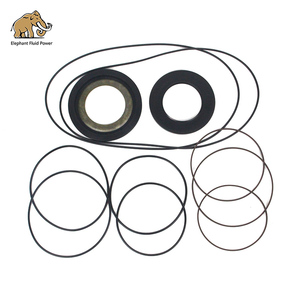

Key Piston Components

| Component | Function | Design Considerations |

|---|---|---|

| Piston Crown | Faces combustion chamber, withstands combustion forces | Flat, domed, or dished designs affect compression and combustion |

| Piston Rings | Seal combustion chamber, control oil consumption | 90mm diameter rings with appropriate tension and materials |

| Piston Skirt | Guides piston in cylinder, transfers force | Full skirt, slipper skirt, or strut designs available |

| Piston Pin Bosses | Connect piston to connecting rod via wrist pin | Must be precisely sized and reinforced for durability |

| Oil Control Features | Manage lubrication and prevent excess oil consumption | Drainage holes, ring design, and surface treatments |

Material Composition

Most 90mm pistons are manufactured from aluminum alloys, offering an excellent balance of weight, strength, and thermal properties. Performance applications may use specialized alloys with silicon, nickel, or magnesium for enhanced durability.

Surface Treatments

Many 90mm pistons feature specialized coatings such as molybdenum disulfide or diamond-like carbon to reduce friction, improve heat management, and extend service life under extreme conditions.

Maintenance Requirements

Proper maintenance of 90mm engine pistons is crucial for ensuring optimal engine performance, efficiency, and longevity. Following these maintenance practices will help prevent premature piston wear and engine failure.

Lubrication Management

The single most important aspect of piston maintenance is proper lubrication. High-quality engine oil creates a protective film between the piston and cylinder wall, reducing friction and heat.

- Use manufacturer-recommended oil viscosity

- Maintain proper oil levels at all times

- Replace oil filters during every oil change

Oil Change Intervals

Regular oil changes are essential for removing contaminants and maintaining proper lubrication properties. Neglected oil changes lead to sludge formation that can block oil passages.

- Change oil every 3,000-5,000 miles for conventional oil

- Synthetic oils may allow 7,500-10,000 mile intervals

- Severe duty requires more frequent changes

Warning: Engine overheating is extremely damaging to pistons. Always monitor temperature gauges and address cooling system issues immediately to prevent piston damage from excessive heat exposure.

Preventive Maintenance

Regular engine maintenance prevents conditions that can damage pistons, such as misfires, detonation, and pre-ignition.

- Maintain ignition system components

- Service fuel injectors and delivery systems

- Keep air intake systems clean

- Address unusual noises or vibrations promptly

Operating Considerations

How you operate your engine significantly impacts piston longevity. Proper driving and operating habits can extend piston life considerably.

- Allow proper warm-up before high loads

- Avoid unnecessary high RPM operation

- Don't overload engine beyond design capacity

- Use appropriate fuel grade for engine design

Maintenance Insight: Listen for "piston slap" - a distinctive tapping noise when cold that diminishes as the engine warms up. This can indicate excessive piston-to-wall clearance and potential premature wear. Early detection can prevent catastrophic failure.

How to Choose the Right 90mm Engine Piston

Selecting the appropriate 90mm piston for your engine requires careful consideration of numerous factors to ensure compatibility, performance, and reliability. Follow this comprehensive selection guide to make an informed decision.

1. Determine Your Engine's Purpose

The intended use of your engine is the primary consideration when selecting pistons:

- Daily Driver: Focus on durability, noise reduction, and fuel efficiency

- Performance Street: Balance between performance and reliability

- Racing Application: Maximum performance with appropriate durability for the competition type

- Heavy-Duty/Commercial: Emphasis on longevity and durability under sustained loads

2. Match Engine Specifications

Ensure the piston is compatible with your specific engine design:

- Verify exact engine make, model, and production year

- Consider any previous engine modifications

- Determine if standard or oversized pistons are needed

- Match connecting rod specifications

- Verify cylinder head compatibility

| Piston Material | Best Application | Advantages | Considerations |

|---|---|---|---|

| Cast Aluminum | Stock replacement, daily drivers | Affordable, good thermal properties | Limited strength for high performance |

| Hypereutectic Aluminum | Moderate performance upgrades | Better strength than cast, good heat tolerance | More brittle than forged pistons |

| Forged Aluminum | High-performance, boosted applications | Superior strength, impact resistance | Higher cost, requires more clearance |

| Coated Pistons | Racing, extreme conditions | Reduced friction, improved heat management | Highest cost, specialized application |

3. Consider Compression Ratio

The piston's crown design significantly affects compression ratio, which impacts power, efficiency, and fuel requirements:

- Flat-Top: Standard compression, versatile for most applications

- Domed: Increases compression ratio for more power (requires higher octane fuel)

- Dished: Decreases compression for forced induction or lower octane fuel

4. Evaluate Piston-to-Wall Clearance

Proper clearance is critical for noise control, heat management, and longevity:

- Stock replacements typically use tighter clearances (0.001"-0.002")

- Performance applications require more clearance (0.004"-0.006")

- Consider your climate and operating conditions

- Material expansion rates affect required clearance

Selection Tip: When in doubt, consult with engine building professionals or the piston manufacturer's technical support team. Providing detailed information about your specific application will help them recommend the optimal piston for your needs.

DIY 90mm Engine Piston Replacement Guide

Replacing engine pistons is an advanced mechanical procedure that requires significant technical knowledge and specialized tools. This guide provides an overview of the process, but is recommended primarily for experienced mechanics.

Important Warning: Piston replacement is a complex mechanical task that requires extensive engine knowledge. Improper installation can cause catastrophic engine failure. If you're unsure about your abilities, consult a professional mechanic for this service.

Preparation and Required Tools

- Complete socket and wrench set (metric and standard)

- Torque wrench

- Piston ring compressor

- Piston ring expander

- Cylinder hone

- Micrometers and dial bore gauge

- Engine assembly lubricant

- Service manual specific to your engine model

- Clean, organized workspace with engine stand

Step-by-Step Replacement Process

-

Engine Removal and Disassembly

Remove the engine from the vehicle and secure it to an engine stand. Drain all fluids including oil and coolant. Label and organize all components during disassembly to ensure proper reassembly.

-

Cylinder Head Removal

Remove the intake manifold, exhaust manifold, and valve cover. Following the proper sequence in your service manual, remove the cylinder head bolts and carefully lift off the cylinder head.

-

Connecting Rod and Piston Removal

Rotate the crankshaft to access the connecting rod bolts. Remove the rod cap, noting its orientation. Carefully push the piston/rod assembly out through the top of the cylinder using a wooden handle.

-

Piston Inspection and Preparation

Measure cylinder bore dimensions for wear. If necessary, have the cylinders professionally bored and honed. Clean all components thoroughly and inspect for damage.

-

New Piston Assembly

Install the piston rings on the new piston following the manufacturer's gap orientation instructions. Assemble the piston to the connecting rod, ensuring proper orientation of both components.

-

Piston Installation

Lubricate the cylinder walls, piston, and rings with assembly lubricant. Use a ring compressor to compress the rings and carefully insert the piston into the cylinder. Orient the piston according to manufacturer specifications (typically an arrow pointing toward the front of the engine).

-

Connecting Rod Installation

Guide the connecting rod onto the crankshaft journal. Install the rod cap in its original orientation and torque the bolts to manufacturer specifications using a torque wrench and the proper sequence.

-

Engine Reassembly

Reassemble all components in the reverse order of disassembly. Use new gaskets and seals throughout. Torque all fasteners to factory specifications following the correct sequences.

Pro Tip: Take photos throughout the disassembly process to serve as reference during reassembly. This visual documentation can be invaluable, especially for complex connections and component orientations.

Frequently Asked Questions

No, 90mm engine pistons are not universally interchangeable between different vehicle makes and models, despite having the same diameter. Each engine design has unique specifications including compression height, pin diameter, ring groove dimensions, and crown configuration that must match precisely. Using an incorrect piston can result in performance issues, mechanical damage, or catastrophic engine failure.

While 90mm pistons alone won't significantly increase power, they can be part of a comprehensive performance upgrade strategy. Performance gains are achieved by combining specialized pistons with other modifications such as:

- Modified cylinder heads with improved port flow

- Performance camshafts with optimized lift and duration

- Enhanced intake and exhaust systems

- Properly tuned engine management systems

Performance pistons typically feature different crown designs, ring packages, and materials that can support higher compression ratios or forced induction when combined with other engine modifications.

90mm engine pistons are manufactured from various aluminum alloys, each offering different performance characteristics:

- Cast aluminum alloys: Common in OEM applications, offering good thermal conductivity and cost-effectiveness

- Hypereutectic aluminum alloys: Feature higher silicon content (12-20%) for improved strength and reduced thermal expansion

- Forged aluminum alloys: Created under pressure for superior strength and durability, ideal for high-performance applications

- Specialized alloys: May include additions of nickel, copper, magnesium, or other elements to enhance specific properties

Some high-end racing pistons may also incorporate steel or titanium components in critical areas for additional strength.

90mm engine pistons don't require specific maintenance beyond standard engine care practices. However, ensuring their longevity depends on:

- Using the manufacturer-recommended oil type and viscosity

- Following proper oil change intervals (or more frequently in severe conditions)

- Ensuring the cooling system functions properly to prevent overheating

- Using fuel with the appropriate octane rating to prevent detonation

- Addressing any unusual engine noises, vibrations, or performance issues promptly

Performance engines with high-compression or forced induction may require more frequent inspection and maintenance of piston-related components.

No, 90mm engine pistons are not used in electric or hybrid electric powertrains. Electric motors operate on entirely different principles:

- Electric motors convert electrical energy directly into rotational motion

- They utilize electromagnetic fields rather than combustion

- Electric drivetrains have far fewer moving parts than internal combustion engines

Hybrid vehicles do contain internal combustion engines that use pistons, but the electric motor components operate independently of the piston system. The 90mm measurement specifically refers to internal combustion engine components.