All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(8357 products available)

A 4x8 plastic HDPE ground mat refers to a specific size of a ground HDPE mat, measuring 4 feet by 8 feet. HDPE, or high-density polyethylene, is a durable plastic known for its strength, lightweight nature, and resistance to water, chemicals, and UV rays. This ground mat is commonly used in various outdoor and industrial settings.

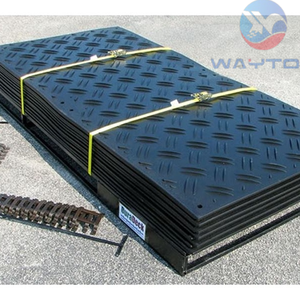

Heavy-Duty Ground Mat

These ground mats are designed for extremely challenging use. Normally, they give support to vehicles that work on the ground, including military trucks and heavy construction machines. Most of these mats possess an innovative grip, assuring perfect performance on uneven or damp surface conditions, which boosting stability and slip safety. They also endure high intensity and demanding conditions since they are manufactured with thicker HDPE and reinforced sections.

Professional Ground Mat

These mats are needed in ground protection mats that are demanded in professionally managed events like concerts, fairs, and sporting activities. Normally, they help vehicles and tireless equipment, such as stage units and lighting systems, work on the surface without causing disaster to the ground. Because of their large size, these mats can be placed adjacent to one another to form extensive pathways or staging areas, minimizing damage to grass or soil. Their light weight ensures that they can be installed fast and simple, and they include provisions to avoid slipping on the given surface.

Construction Ground Mats

In construction projects, 4x8 plastic ground mats are deployed frequently to safeguard the ground, especially in ecological sensitive areas. Apart from providing a level area for the given construction tools and vehicles, these mats also avert soil disintegration and minimize disturbance to unblemished sites. They usually carry large weights and endure hazardous weather elements and chemical exposures found in construction settings. Many of them are marked with visibility colors to enhance safety.

Tactical Ground Mat

HDPE ground mats are needed in military applications to offer a stable working ground surface in unpaved areas. They create a designated area for operations, reducing the impact of travel on the existing vegetation and soil. Their toughness, coupled with resistance to chemical exposures and moisture, makes them suitable for outdoor use under numerous circumstances. They can be reused a number of times and easily washed after use in the field.

Texture and Grip

The texture of ground protection sheets is deliberate for the feet to ensure protection is assured regardless of the coming precipitation situation. These mats have a non-slip surface feature that gives traction in wet and dry conditions. This will minimize the possibility of slippage, which is especially essential if vehicles operate on inclined gradients. Normally, the textured patterns differ and can include dots, ridges, or raised designs that augment the contact with the given surface.

Environmental Resistance

It is important for ground mats to be designed for environmental use. The 4x8 plastic HDPE ground mats possess the quality of UV pointing and moisture pointing, so they can easily be used anywhere, be it tropical or temperate. While HDPE does not absorb moisture, it also stands the ill effects of rain or water; UV light exposure typically leads to cracking or weakening the material. The common HDPE is UV light resistant, ensuring the mats retain their integrity after long hours in the sun.

Weight and Portability

The ground protection mats are usually portable and weigh quite well for easy transportation. To enable handling by just one person, they are designed so that their thickness does not exceed 1 inch. They can be stored in vans, ferries, or trucks with no space complications. Once they are deployed, stakes or connectors assist in holding adjacent mats firmly in position as the mat is moved around.

Edge Design

The edges of the ground mats are also deliberated to ensure functionality and safety. More often than not, they possess a beveled edge that aids in enhancing smooth vehicle entry and decreases edge chipping possibility. This inset edging not only helps in reducing the chances of tripping, but it also assists in seamlessly interlinking multiple mats together to form a broad, consistent working surface.

Compact Size

The size of the 4x8 plastic HDPE ground mat is very ideal in many respects. Usually, the measurements are flexible enough to be used in most space constraints. Also, the size allows easy interconnection with other identical pieces to form bigger surfaces when appropriate.

These mats are highly versatile and can be used in a variety of scenarios, including:

Construction Sites

On the first day of construction, ground mats help reduce the impact on soil and vegetation while creating a stable surface for vehicles and equipment. When working at any site, whether wet, muddy, or dry, the ground mats provide a platform that helps prevent erosion and keep the project on schedule. Apart from that, they are useful on soft and fragile ground surfaces where dislocation and damage need to be minimized.

Outdoor Events

Often, concert promoters and event organizers use these mats to create smooth, stable paths and working areas for attendees when organizing outdoor events such as concerts, festivals, and fairs. They protect the existing vegetation from being uprooted or damaged, and the mats give a clean and dry area for vendors, stages, and seating. Because of their portability, they can easily be carried and placed in different areas of the venue as required.

Emergency and Military Operations

In some conditions, HDPE ground mats are used in military operations to bring a stable working surface in undeveloped and ecological areas. In such areas, stability is difficult to find, and these mats give it to vehicles and soldiers. They are particularly useful in sandy, marshy, or rocky soils since they provide a surface on which the vehicles can maneuver without sinking or slipping.

Military Use

The ground protection mat provides a reliable working surface for troops and vehicles in rugged or unstable terrain. It reduces the impact on natural ground cover and provides a stable platform for operations.

Agricultural Applications

Occasionally, farmers use the mats in some of their fields to shield the conditions and have a stable place to park machines during planting or harvesting seasons. The mats keep the machines from sinking into the ground, doing damage to the valuable topsoil, or giving the impression that they are working on a muddy or moist floor.

Tent and RV Camps

These mats are put to use in camping grounds to offer a level place for tents and recreational vehicles. They keep campers off the mud in times of rain, or they keep the ground dry, enabling them to have a comfortable experience without worrying about the conditions below them. Besides, the mats aid in reducing wear and tear on the ground, ensuring that the campsite remains intact for future users.

Thickness

The thickness of the 4x8 plastic HDPE ground mat is critical to its performance capabilities. The thickest mats have the greatest tensile strength and bear the heaviest load without warping, bending, or breaking.

These mats can be safely used in high-demand jobs like heavy traffic construction sites or military operations. On the other hand, there are thinner mats ideal for light-duty use, like at outdoor events or on fragile grass surfaces. Although not as robust, the lighter designs are easier to handle and store, which are periodically needed for short-term applications.

Weight Capacity

These 4x8 ground mats can withstand many loads, depending on the thickness and quality of the HDPE used to make them. Heavily constructed mats are specifically made to bear maximum loads, whether from large construction traffic, military vehicles, or heavy machinery.

In contrast, lighter-duty mats are more appropriate to event equipment, tents, or light vehicles. In all cases, the weight limits are specified by the manufacturers, and the limits should always be observed to prevent possible failures and other mat-related problems.

Installation and Setup

Ground mats are easy to set and install. First, the area should be cleaned and brushed off any debris or vegetation that might interfere with the mat. The mats should be laid out so that they form a path or working area suitable for the activity that is going on.

Next, the adjoining mats should be linked together by using connection pins or by interlocking edges. If needed, ground stakes should be driven into the mat corners to secure them, especially when windy or unstable. Finally, one should check that the mat was placed evenly and properly interlinked and that it looked ready for use.

Cleaning and Care

HDPE ground mats are frequently lauded for their easy cleaning procedures. A simple soap-and-water cleaning removes general dirt and residues. For stubborn stains, one could use a gentle solution of vinegar and water or a dedicated plastic cleaner.

They should not be left under constant heavy items for longer periods since this may lead to imprints on the material. To maintain the mats' pristine state, a thorough storage in a cool, dry place is recommended when the mat is not in use. HDPE is famous due to its resilience characteristics, but it also requires regular maintenance to prolong its lasting usefulness.

A: HDPE ground mats are a great way to create stable surfaces over existing soil and vegetation where vehicles and equipment might have a hard time operating. These mats provide a hard, flat, and stable surface for anything from construction equipment to military vehicles, event staging, or outdoor wedding and party tents.

A: The 4x8 plastic HDPE ground mats can normally be used at construction sites to protect soil and vegetation; during outdoor events, to create flat, dry areas for guests, vendors, and performers; by the military to support vehicles in rough terrain; on farms to prevent mud from overtaking equipment and campers to keep dry ground under tents and RVs.

A: These mats are tough enough to handle a wide variety of conditions. High-density polyethylene, or HDPE, is a type of plastic that is strong although lightweight. These mats won't break or crack easily. They are resistant to chemicals commonly found at construction sites, like fuels and solvents, and weather, such as rain and intense sunlight.

A: These mats are portable, easy to carry, and store. Although they are large, they are designed so that their thickness won't be more than 1 inch, which makes handling them smoother. They can be stacked or laid flat for storage.

A: Maintenance of ground protection sheets involves frequent washing with soap and water, along with storing them in a shaded place when not in use. It is advised not to place heavy objects on the mats for extended periods.